A Guide to Choosing the Right Vision Based Inspection System

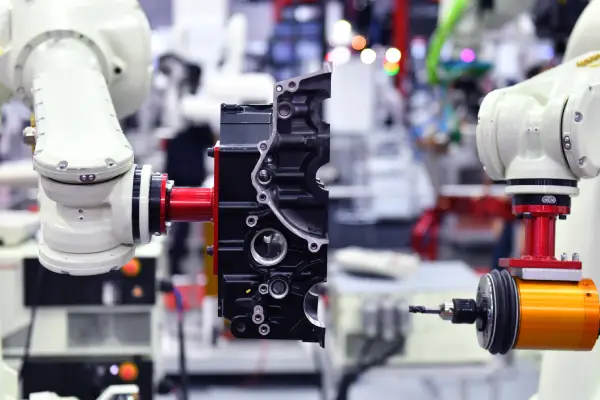

Table of content Introduction What Can Vision Based Inspection Systems Do? Vision Based Inspection Examples Steps to Choose the Right Vision based Inspection System 1. The Inspection System Should be AI Driven 2. Look for Specialization in Your Industry 3. Go Through Customer Reviews 4. Choosing for employee Safety Conclusion Introduction Vision inspection systems harness automated digital imaging to fulfill crucial manufacturing tasks. These tasks encompass steps that require a high degree of precision such as quality control, sorting, and verification. Regarded as indispensable by industrialists today, the technology liberates production line staff for more strategic roles leaving the cumbersome work to the machines. Efficiency of the vision inspection system lies in their high-speed operation, which results in significant time and cost savings for manufacturers. These systems excel in rapid data processing and continually improve through artificial intelligence integration. Furthermore, their capability to generate high-resolution images allows operators to scrutinize product defects with exceptional detail, contributing to less errors in the manufacturing process. In this article, we take a closer look at some of the vision-based inspection solutions and choose one that is right for you. What Can Vision Based Inspection Systems Do? Intelligent inspection systems are often equipped with multiple cameras, along with video and lighting features. These vision systems excel in measuring parts, verifying their correct positioning, recognizing shapes and more. Capable of high-speed measurement and sorting, they employ computer software to process captured images during the assessment process, extracting valuable data. Integration into production lines allows these systems to offer a continuous flow of information, ensuring real-time insights and efficient decision-making for enhanced operational precision. Vision Based Inspection Examples Here are some of the frequently used vision inspection systems in different industries: Steps to Choose the Right Vision based Inspection System While you may already know precisely the vision-based inspection you need for your industry, choosing the system goes well beyond the technology. It is equally important to choose the right partner/vendor who can deliver precisely what you need and ease the process of implementation. So here’s how you arrive at your solution before implementing vision based inspection: 1. The Inspection System Should be AI Driven Legacy systems with simple programming have been the standard since visual-based inspection came into existence. However, AI reinforcement can fundamentally augment detection systems and increase the scope of error detections in production. Visual-based Inspection, powered by deep learning algorithms, elevates the process by enabling the differentiation of parts, characters, and anomalies. This mirrors the capacity of human visual defect detection while leveraging the computational efficiency of a computer system. What’s more, unlike human operators who are subject to fatigue and experience, the AI system performs consistently. 2. Look for Specialization in Your Industry Selecting a vision-based inspection system tailored to your industry can make a significant difference. Opting for a partner specializing in your specific sector is not merely a matter of cost; it is an investment in precision and expertise. Entrusting an experienced partner even if their service may entail a slightly higher cost, outweighs the risks of inexperienced handling. A specialized partner comprehends the intricacies of your industry, foreseeing and addressing impending challenges with well-tailored solutions. The decision to engage an industry-focused expert ensures the perfect integration of vision-based inspection systems, enhancing efficiency and mitigating risks associated with subpar solutions. 3. Go Through Customer Reviews When choosing a partner, go deeper into customer reviews, industry relevance, and challenges faced. Scrutinize project quality, services, timelines, duration, and costs comprehensively to avoid partnering with an unsuitable vendor. Assess their success rates and industry track record, examining their impact on businesses. Analyze their approach and ensure their solutions align precisely with your needs. Explore their client base from past and present to gauge their expertise and the breadth of industries they are able to serve. Additionally, verify if their technology is a good match for your requirements and does not fall short of any future upgrades you have planned. 4. Choosing for Employee Safety When picking vision based systems for employee safety, it is crucial to look for a solution that offers more features than what you need. For instance, the system should incorporate face recognition to detect individuals not adhering to mask or safety gadget guidelines. It should also adeptly identify damaged equipment, such as compromised harnesses, helmets, or other PPE, facilitating prompt alerts and replacements. The system must also monitor adherence to safety protocols like social distancing, machinery standard operating procedures, and plant safety protocols, instantly alerting authorities in case of non-compliance. Conclusion By adopting vision-based inspection systems, industries can harness a powerful system for precision and efficiency in manufacture. The integration of advanced cameras, software, and artificial intelligence not only boosts defect detection but also finds application in end-of-line inspections and part segregation.Now that you know the different types of vision-based systems that exist and how to choose the right tech partner for your process, it is time to take the next step! Get in touch with our team and learn how sensing technology and automation can boost your productivity today!

Read More10 Benefits of Vision-Based Inspection Systems in Manufacturing

Table of content Advantages of Vision-Based Inspection Systems Conclusion In the rapidly evolving realm of modern manufacturing, the pursuit of impeccable product quality and streamlined efficiency has become the linchpin of success. Manufacturers are ceaselessly exploring innovative methods to ensure the precision of their products while optimizing intricate production processes. Vision-based inspection systems have emerged as a transformative and indispensable technology in this pursuit. Leveraging advanced imaging techniques coupled with the power of artificial intelligence, these systems conduct meticulous inspections that empower manufacturers to achieve unparalleled levels of quality and productivity. In this article, we will explore the ten pivotal and multifaceted benefits of integrating vision-based inspection systems into the fabric of the manufacturing landscape. Advantages of Vision-Based Inspection Systems Vision-based inspection systems have emerged as a transformative force in manufacturing, combining advanced imaging and artificial intelligence to revolutionize quality control. Their benefits reverberate across the spectrum: 1. Elevated Quality Assurance Quality is the cornerstone of manufacturing success, and vision-based inspection systems are at the forefront of upholding this standard. Equipped with unparalleled precision, these systems excel in detecting even the most minuscule defects that might elude the human eye. Through their high-resolution imaging capabilities employed at various production stages, these systems provide a comprehensive canvas for defect identification. These systems are primed to identify and eliminate faulty products, be it surface irregularities, dimensional deviations, or alignment discrepancies. This ensures that only products meeting stringent quality benchmarks reach the market. 2. Unsurpassed Accuracy and Consistency Despite their unwavering diligence, human inspectors can succumb to fatigue and the potential for variability. Vision-based inspection systems, in stark contrast, exhibit unwavering precision and consistency. These systems consistently maintain their remarkable accuracy levels throughout the inspection process, effectively eradicating the potential for errors stemming from human limitations. The reliability and uniformity in product quality generated by these systems are of paramount importance, particularly in industries such as electronics, pharmaceuticals, and automotive manufacturing. 3. Expedited Inspection Speed Conventional manual inspection methods often prove to be time-intensive, inevitably leading to production bottlenecks and costly delays. Vision-based inspection systems revolutionize this by expediting the inspection process at remarkable speed. Propelled by high-resolution cameras and sophisticated algorithms, these systems process colossal volumes of data in real time. This capability ensures the seamless movement of products through the production line without compromising the rigor of the inspection process. 4. Tangible Cost-Efficiency The seamless integration of vision-based inspection systems translates into substantial cost savings over the long haul. Through the automation of inspections, manufacturers significantly reduce their reliance on labor-intensive manual assessments. This reduction not only slashes labor costs but also mitigates expenses related to defects, rework, and potential recalls. Furthermore, the heightened operational efficiency and minimized downtime amplify production throughput, thereby enhancing revenue streams and optimizing the overall Return on Investment (ROI). 5. Adaptability and Flexibility By their very nature, manufacturing processes are susceptible to evolution, often triggered by shifts in product design or specifications. Vision-based inspection systems truly shine in such dynamic scenarios, showcasing their inherent adaptability and flexibility. With the capacity to swiftly program new inspection criteria, these systems enable seamless transitions between diverse product variants. This adaptability translates to minimized setup times and heightened operational agility, which is crucial in staying ahead in today’s fast-paced manufacturing landscape. 6. Insights Driven by Data Beyond their role in defect detection, vision-based inspection systems also emerge as robust data repositories. These systems generate abundant data during the inspection, capturing crucial information about defects, patterns, and anomalies. Manufacturers can harness this trove of data to glean valuable insights into their production processes. This includes pinpointing areas for optimization, refining process parameters, and even preemptively identifying potential issues before they manifest. The data-driven approach empowers manufacturers to make well-informed decisions that elevate both product quality and production efficiency. 7. Non-Intrusive Evaluation Certain manufacturing processes involve intricate components particularly susceptible to damage through contact-based inspection methods. Vision-based inspection systems offer a non-intrusive solution, relying on visual imaging without requiring physical contact. This characteristic renders them ideal for scrutinizing delicate or sensitive items, ensuring that products remain pristine and intact throughout the inspection process. 8. Mitigation of False Positives and Negatives In the intricate domain of inspections, the challenge lies in minimizing the occurrence of false positives (erroneously identifying a defect) and false negatives (failing to detect a defect). Vision-based inspection systems employ advanced algorithms and machine learning to navigate this challenge. Drawing insights from vast datasets, these systems progressively enhance their ability to differentiate between authentic defects and minor product variations. The result is an elevated level of accuracy, significantly reducing instances of both false positives and negatives. 9. Streamlined Documentation and Reporting Manufacturers often find themselves in need of meticulous records of their inspection processes for regulatory compliance and rigorous quality control audits. Vision-based inspection systems simplify this task by autonomously generating comprehensive reports and documentation. These reports encompass not just images but also measurements and other pertinent data collected during the inspection process. This streamlined approach not only expedites compliance efforts but also furnishes an exhaustive record of product quality, an invaluable resource for quality control analysis and ongoing process optimization. 10. Gaining a Competitive Edge In the current cutthroat manufacturing landscape, maintaining a competitive edge is no longer a choice but an imperative. The adoption of vision-based inspection systems confers a tangible competitive advantage. Through consistently delivering top-tier products, manufacturers cultivate a reputation for reliability and excellence in the market. This, in turn, translates into heightened customer satisfaction, recurrent business, and enduring brand loyalty, all of which contribute to a formidable market presence. Conclusion Vision-based inspection systems represent a revolutionary amalgamation of cutting-edge imaging technology and artificial intelligence within the manufacturing sector. Their impact is wide-ranging, spanning from elevated quality assurance and unparalleled accuracy to expedited inspection speeds and quantifiable cost-efficiency. Manufacturers embracing this technology embark on a trajectory toward heightened success, simultaneously elevating both product quality and operational efficiency. With the help of Prescient Technologies, commence your journey towards efficiency, accuracy, reliability, and cost-efficiency right away. As technology continues its rapid evolution, the pivotal

Read MoreHow 3D Product Configurators propel sales and customer satisfaction

Introduction Interaction with 3D Product Configurators What are 3D Product Configurators? Boosting sales and satisfaction Introduction Customers are often reluctant to buy customized products because they don’t know the outcome. People are often hesitant to purchase made-to-order or engineered-to-order products after being disappointed. Sometimes, people may order something they thought was great but get a completely different product. It can be challenging to return custom-made products purchased online. Customers can overcome this fear with 3D product configurators. Increasingly popular in the build-to-order industry, 3D product configurators help customers visualize and feel their purchasing product. The 3D product configurator software does not require a third-party plugin, and they work offline as well. They encourage customer participation by allowing them to virtually test product combinations. They enable customers to customize their options to their liking, and they’re available on any device without requiring plugins. As a result, this software has various applications for different industries and sectors. Interaction with 3D Product Configurators 3D product configurators allow you to estimate complex products quickly and accurately. It is vital for those manufacturers that must handle increased product complexity. Customers have always wanted to have their own customized stuff, and today they have no problem paying a premium for it. They want to be involved in the design of products and have the opportunity to influence their development. It puts pressure on manufacturers to find ways to make their processes more accessible to people outside of their four walls. It was long before consumers could be expected to accept standardized products that fit all. Modern customers desire the ability to customize and personalize products according to their individual needs. This is one of the most demanding competencies manufacturers have to focus on. It means a gradual relocation to mass customization from mass production. The rise of 3D product configuration software has prompted many online retailers to integrate product visualization into their eCommerce sites seamlessly. In the past, customers had to select a pre-made model. Now, they can choose a product by selecting from thousands of combinations. Customizing a product is the key to attracting and retaining customers. Whether your customers choose a color or material, they can easily envision it with the help of 3D configurators. What are 3D Product Configurators? In today’s visual economy, interactive product experiences are a must for customers. 3D product configurators are valuable tools for illustrating how products can be customized. In the past, a person could only see the final product or design iteration in full detail in a physical location, such as a showroom or with manufacturing samples. This has been changed by digital 3D configuration tools, which allow products to be created directly at the customer’s fingertips, giving them unique options rather than standard off-the-shelf designs. Using the visualization tool, users can see designs in real-time. It includes rotating the model or zooming in to view the fine details of each option. 3D models react instantly to changes in color and dimensions. Users can then immediately reconsider their selections and reselect the features and options that are most important to them until they find the best design. It is significant for designers of complex products, as it can be challenging to visualize how features and options related to each other. Boosting sales and satisfaction The increasing use of 3D configurators has increased customer satisfaction, engagement, and average basket value, increasing sales and conversion rates. These tools can monitor customer behavior and combine this information with other marketing data to create more relevant products and personalized interactions. And the best part is that they’re free to use in any way you see fit, allowing you to create a customized experience for every customer. 3D configurators can help you boost customer satisfaction and sales. They enable customers to select and change various aspects of products, including color, wheel configuration, seats, and even lighting and vision. By allowing customers to personalize their purchases, 3D product configurators enhance the experience of online shoppers. They create an emotional connection with the products, increasing the chances of making a purchase. Understanding customer behavior is one of the essential pillars of an e- commerce business. By giving customers a chance to see products and choose the features that matter to them, 3D configurators smooth out this process and make it easier for companies to track and measure it. Boosting customer satisfaction and sales with 3D configurators will give you a competitive edge over other brands and make you stand out from the competition. What does the future say? 5G, the next generation in high-speed mobile networks, will provide more data, and thus more detail, to users. As such, rich content is expected to continue to increase. However, augmented reality is the most significant development and opportunity. Manufacturers will be able to present an immersive experience to customers thanks to the rapid advancement in augmented reality technology’s usability and capability. This will allow them to educate them about the specific capabilities and fit of particular products or configurations. Seamless experiences like these are crucial to increasing brand awareness and loyalty and ultimately generating additional sales orders. The future of 3D configurators for customer satisfaction and sales will involve new technologies and innovations. AR and 3D technologies are becoming more affordable and accessible. The cost of 3D image configurators can be recovered within two to three months of investment. By allowing consumers to customize their products in AR, retailers will be able to create a direct-to-consumer sales channel. A 3D product configurator can be an essential tool for businesses looking to enhance customer engagement and boost sales and ROI. This technology makes it possible to provide customers with a 360-degree view of a product before purchasing it. With the 4th Industrial Revolution coming close, brands must start putting consumers in the driver’s seat. Brands can quickly and efficiently fulfill their needs when customers know exactly what they want. By letting them customize products and make them unique, brands can quickly meet customer demand and boost sales. As the customer becomes an integral part of the

Read More