5 Ways to Optimise Your Product Configurator: A Comprehensive Guide

Table of content The Growing Importance of Product Customization 1. User-Friendly Interface 2. Streamlined Product Options3. Real-Time Pricing and Availability4. Integration with CRM and Analytics5. Customer Support and Feedback Conclusion In today’s competitive business landscape, offering customizable products is a key strategy for many companies. Customers appreciate the ability to tailor products to their specific needs and preferences, and this can lead to increased sales and customer loyalty. However, managing a product configurator effectively is no small task. It requires careful planning and optimization to ensure a seamless and satisfying customer experience. This comprehensive guide will explore five ways to optimize your product configurator and maximize its benefits. The Growing Importance of Product Customization Before diving into optimization strategies, let’s take a moment to understand why product customization has become increasingly important in the modern marketplace. Now that we’ve established the significance of product customization, let’s delve into the five essential ways to optimize your product configurator for maximum success. 1. User-Friendly Interface A user-friendly interface is the cornerstone of a successful product configurator. Customers should be able to easily navigate through the configuration process without feeling overwhelmed or confused. Here are some tips to create a user-friendly interface: A. Intuitive Design: Keep the design clean and intuitive. Use clear and concise labels for options, buttons, and features. Visual cues like icons and color coding help users quickly understand the interface. B. Step-by-Step Guidance: Break down the configuration process into manageable steps. Provide clear instructions and guidance at each step to help users make informed choices. A progress bar can also be helpful to show users how far along they are in the configuration process. C. Responsive Design: Ensure that your product configurator is responsive and works seamlessly on various devices, including desktops, tablets, and smartphones. This is crucial for catering to a wide range of customers. D. Visual Previews: Include visual previews of the product as users make selections. This allows customers to see how their choices impact the final product, which can be a powerful motivator for completing the configuration process. E. Error Handling: Implement robust error handling to catch and address any mistakes or inconsistencies in the configuration. Provide clear error messages and suggestions for correction to minimize user frustration. 2. Streamlined Product Options While customization is valuable, it’s essential to balance offering enough options and overwhelming customers with choices. Here’s how you can streamline product options effectively: A. Relevant Choices: Offer choices that are relevant to the product and the customer’s needs. Avoid including options that are too niche or rarely selected. Conduct market research to identify the most popular customization options. B. Smart Defaults: Set intelligent default options based on common customer preferences. These defaults can save customers time and effort while still allowing them to customize as desired. C. Conditional Logic: Use conditional logic to display options based on previous selections. This ensures that customers are only presented with choices that make sense in the context of their previous selections, reducing confusion. D. Bundling: Consider offering pre-configured bundles or packages that include popular combinations of customization options. This simplifies the decision-making process for customers who may be overwhelmed by too many choices. Also Read: What is RFID and how does RFID tags, RFID readers work 3. Real-Time Pricing and Availability Customers often want to know how their customizations impact the final price and product availability. Providing real-time pricing and availability information is crucial for transparency and customer satisfaction. Here’s how to achieve this: A. Dynamic Pricing: Implement a dynamic pricing system that adjusts the total price as customers make customization selections. Clearly display the price changes so that customers can make informed decisions. B. Inventory Tracking: Integrate your product configurator with your inventory management system to ensure that customers are informed about the availability of their customized product. If a particular configuration is out of stock, provide estimated restock dates or alternative options. C. Pricing Breakdown: Offer a detailed pricing breakdown that shows how each customization choice contributes to the final cost. This transparency builds trust and helps customers understand the value they are getting. 4. Integration with CRM and Analytics To optimize your product configurator, you need insights into customer behavior and preferences. Integrating it with Customer Relationship Management (CRM) systems and analytics tools can provide valuable data. Here’s how: A. Customer Profiles: Use CRM integration to create and update customer profiles based on their configuration choices. This allows you to personalize future marketing efforts and product recommendations. B. Analytics Tracking: Implement robust analytics tracking to monitor user interactions with the configurator. Track drop-off points, popular customizations, and any usability issues. Use this data to make continuous improvements. C. A/B Testing: Conduct A/B tests to compare different configurations of your product configurator. Test variations in design, layout, and the number of customization options to determine what resonates best with your audience. 5. Customer Support and Feedback Even with a well-optimized product configurator, some customers may have questions or encounter issues. Providing excellent customer support and collecting feedback is essential for ongoing improvement: A. Live Chat and FAQs: Offer live chat support during the configuration process to assist customers in real time. Create a comprehensive FAQ section that addresses common questions and issues. B. Feedback Forms: Implement feedback forms at the end of the configuration process to gather customer insights. Ask for their opinions on usability, customization options, and overall satisfaction. C. Continuous Iteration: Use customer feedback to drive continuous iteration and improvement of your product configurator. Identify pain points and areas where customers struggle, and make necessary adjustments. Also Read: The emergence of computer vision market Conclusion A well-optimized product configurator can be a powerful tool for increasing sales and enhancing the customer experience. By focusing on a user-friendly interface, streamlined options, real-time pricing and availability, integration with CRM and analytics, and excellent customer support and feedback, you can create a configurator that not only meets but exceeds customer expectations. Remember that optimization is an ongoing process, and staying attuned to customer

Read MoreA Comprehensive Guide to Implementing a Product Configurator in Manufacturing

Table of content Introduction Benefits of Implementing a Product Configurator Understanding Product Configurators What is a Product Configurator? Types of Product Configurators Applications and Use Cases Planning for Product Configuration Selecting the Right Product Configurator Software Designing the Product Configuration Rules Defining Product Constraints and Dependencies Establishing Rule Hierarchy Creating a User-Friendly Configurator Interface Implementing and Integrating the Configurator Ensuring a Seamless Customer Experience Overcoming Challenges and Pitfalls Case Studies: Successful Product Configurator Implementations Conclusion Companies are continually looking for new, effective ways to deliver tailored products in the highly competitive manufacturing industry. A product configurator in manufacturing is a potent tool that enables these industries to visualize and design their preferred items. This extensive manual seeks to give producers a thorough grasp of product configurators and a step-by-step process for successfully adopting them. It also covers every step they need to fully realize the possibilities of a product configurator in production, from idea conceptualizing to choosing the appropriate software and ensuring seamless integration. Introduction Customers now want tailored items that cater to their interests, which has resulted in a paradigm shift in consumer demands for the manufacturing sector. Manufacturers are increasingly using product configurators to address this growing trend. An interactive and immersive experience is provided by a product configurator, which is a software that allows customers to design products based on specified options and rules. This manual intends to help manufacturers comprehend how to successfully deploy a product configurator in manufacturing. Benefits of Implementing a Product Configurator Manufacturers can gain a wide range of advantages by using a product configurator. These include improved client interaction, more effective operations, shorter lead times, fewer mistakes, more sales conversions, and more efficient production procedures. A properly implemented product configurator may set a business apart from its competitors and boost customer loyalty. Understanding Product Configurators Understanding the principles is crucial before moving on to implementation. You can reap the advantages of product configurators and promote business growth by obtaining a thorough understanding of them. What is a Product Configurator? A product configurator allows customers to personalize and visualize products according to their preferences. They select and combine various features, options, and components to create a customized product. The configurator validates the chosen options against predefined rules and constraints to ensure feasibility and generate accurate specifications. Types of Product Configurators Product configurators can be categorized into three main types: Applications and Use Cases Additionally, product configurators are used in business-to-business (B2B) scenarios to configure intricate industrial machinery and equipment conveniently. Planning for Product Configuration Proper planning sets the stage for a successful product configurator implementation. By investing time and effort in the planning phase, you can ensure a well-defined roadmap for implementing your product configurator. It helps you achieve your desired outcomes efficiently. Before implementing a product configurator, it is essential to define the scope and objectives of the project. This involves identifying the target market, understanding customer preferences, and determining the level of customization to be offered. Clear goals and a well-defined scope will guide the implementation process and ensure alignment with business objectives. The manufacturer must identify the customization choices available for a product’s design. This comprises adaptable features, elements, materials, colors, sizes, and other pertinent characteristics. You can choose the most desirable customization by carefully examining consumer needs, market trends, and rivals’ products. The complexity of the product plays a crucial role in designing an effective product configurator. Manufacturers must assess the complexity of the products and evaluate if they can configure them within the desired constraints. Complex products often require more sophisticated configurator solutions and meticulous rule definitions. A thorough understanding of data needs and system integration helps to implement a product configurator. Manufacturers should assess their current data infrastructure, which includes product details, costs, available stock, and manufacturing capacities. It’s vital to determine appropriate integration points with current enterprise systems. These include ERP (Enterprise Resource Planning) and CRM (Customer Relationship Management). Selecting the Right Product Configurator Software The correct software must be chosen in order for your product configurator installation to succeed. You can then support the goals of your business and provide a solid foundation for customization and efficiency. Let’s review some crucial elements: Manufacturers should take into account elements like the vendor’s experience, industry knowledge, track record, and customer feedback. Selecting a dependable, seasoned vendor with a solid, scalable solution is essential. Manufacturers should evaluate the features and functionality of different product configurator software solutions. Key features include a user-friendly interface, real-time visualization, 3D modeling, and dynamic pricing. They should also check for automated bill of materials generation, integration capabilities, and reporting and analytics tools. Software for product configuration should be scalable to enable future expansion. It should also be adaptable to changing consumer expectations. Additionally, it should be adaptable to shifting market trends, product configurations, and corporate procedures. It should also be able to manage big product catalogs and support many product lines. Seamless integration with existing enterprise systems is critical for efficient operations. The product configurator software should integrate smoothly with ERP, CRM, PLM (Product Lifecycle Management), and other relevant systems. It ensures accurate data synchronization, efficient order management, and streamlined production processes. Designing the Product Configuration Rules A successful product configurator’s foundation consists of effective configuration rules. Let’s examine several configurators and show how to set dependencies and rules. Offer accurate and practical setups and give clients a seamless customization experience by defining rule hierarchies and limitations. Rule-based configurators utilize predefined rules and logic to guide the configuration process. Manufacturers need to define these rules, which include compatibility constraints, dependencies among features, and valid combinations. Ensure the rules accurately represent the product’s configuration possibilities while preventing invalid or impractical combinations. Constraint-based configurators focus on defining constraints and dependencies among product features. These constraints can be in the form of logical rules, mathematical equations, or conditional statements. Always identify the dependencies and constraints between different features and establish validation mechanisms. It helps the configurator to generate feasible and valid configurations. Knowledge-based configurators leverage artificial

Read MoreHow 3D Product Configurators propel sales and customer satisfaction

Introduction Interaction with 3D Product Configurators What are 3D Product Configurators? Boosting sales and satisfaction Introduction Customers are often reluctant to buy customized products because they don’t know the outcome. People are often hesitant to purchase made-to-order or engineered-to-order products after being disappointed. Sometimes, people may order something they thought was great but get a completely different product. It can be challenging to return custom-made products purchased online. Customers can overcome this fear with 3D product configurators. Increasingly popular in the build-to-order industry, 3D product configurators help customers visualize and feel their purchasing product. The 3D product configurator software does not require a third-party plugin, and they work offline as well. They encourage customer participation by allowing them to virtually test product combinations. They enable customers to customize their options to their liking, and they’re available on any device without requiring plugins. As a result, this software has various applications for different industries and sectors. Interaction with 3D Product Configurators 3D product configurators allow you to estimate complex products quickly and accurately. It is vital for those manufacturers that must handle increased product complexity. Customers have always wanted to have their own customized stuff, and today they have no problem paying a premium for it. They want to be involved in the design of products and have the opportunity to influence their development. It puts pressure on manufacturers to find ways to make their processes more accessible to people outside of their four walls. It was long before consumers could be expected to accept standardized products that fit all. Modern customers desire the ability to customize and personalize products according to their individual needs. This is one of the most demanding competencies manufacturers have to focus on. It means a gradual relocation to mass customization from mass production. The rise of 3D product configuration software has prompted many online retailers to integrate product visualization into their eCommerce sites seamlessly. In the past, customers had to select a pre-made model. Now, they can choose a product by selecting from thousands of combinations. Customizing a product is the key to attracting and retaining customers. Whether your customers choose a color or material, they can easily envision it with the help of 3D configurators. What are 3D Product Configurators? In today’s visual economy, interactive product experiences are a must for customers. 3D product configurators are valuable tools for illustrating how products can be customized. In the past, a person could only see the final product or design iteration in full detail in a physical location, such as a showroom or with manufacturing samples. This has been changed by digital 3D configuration tools, which allow products to be created directly at the customer’s fingertips, giving them unique options rather than standard off-the-shelf designs. Using the visualization tool, users can see designs in real-time. It includes rotating the model or zooming in to view the fine details of each option. 3D models react instantly to changes in color and dimensions. Users can then immediately reconsider their selections and reselect the features and options that are most important to them until they find the best design. It is significant for designers of complex products, as it can be challenging to visualize how features and options related to each other. Boosting sales and satisfaction The increasing use of 3D configurators has increased customer satisfaction, engagement, and average basket value, increasing sales and conversion rates. These tools can monitor customer behavior and combine this information with other marketing data to create more relevant products and personalized interactions. And the best part is that they’re free to use in any way you see fit, allowing you to create a customized experience for every customer. 3D configurators can help you boost customer satisfaction and sales. They enable customers to select and change various aspects of products, including color, wheel configuration, seats, and even lighting and vision. By allowing customers to personalize their purchases, 3D product configurators enhance the experience of online shoppers. They create an emotional connection with the products, increasing the chances of making a purchase. Understanding customer behavior is one of the essential pillars of an e- commerce business. By giving customers a chance to see products and choose the features that matter to them, 3D configurators smooth out this process and make it easier for companies to track and measure it. Boosting customer satisfaction and sales with 3D configurators will give you a competitive edge over other brands and make you stand out from the competition. What does the future say? 5G, the next generation in high-speed mobile networks, will provide more data, and thus more detail, to users. As such, rich content is expected to continue to increase. However, augmented reality is the most significant development and opportunity. Manufacturers will be able to present an immersive experience to customers thanks to the rapid advancement in augmented reality technology’s usability and capability. This will allow them to educate them about the specific capabilities and fit of particular products or configurations. Seamless experiences like these are crucial to increasing brand awareness and loyalty and ultimately generating additional sales orders. The future of 3D configurators for customer satisfaction and sales will involve new technologies and innovations. AR and 3D technologies are becoming more affordable and accessible. The cost of 3D image configurators can be recovered within two to three months of investment. By allowing consumers to customize their products in AR, retailers will be able to create a direct-to-consumer sales channel. A 3D product configurator can be an essential tool for businesses looking to enhance customer engagement and boost sales and ROI. This technology makes it possible to provide customers with a 360-degree view of a product before purchasing it. With the 4th Industrial Revolution coming close, brands must start putting consumers in the driver’s seat. Brands can quickly and efficiently fulfill their needs when customers know exactly what they want. By letting them customize products and make them unique, brands can quickly meet customer demand and boost sales. As the customer becomes an integral part of the

Read MoreWhat is CAD Automation and its Impact on Manufacturing

Running a manufacturing business is no child’s play. Amid cutthroat competition, manufacturers must develop innovative ways to stay afloat in the market by churning out well-made products, addressing rapid customer demands, boosting sales, etc. Often, time-consuming issues have been a setback for such businesses. The back and forth between engineering and sales teams have been a grueling, arduous task since creating CAD models and drawings takes meticulous work and a long time. However, CAD automation is a game-changer and, in all honesty, a lifesaver. CAD Automation denotes automated tools and processes to create CAD models, manuals, and setup CAD workflows. CAD automation adds value to an engineer’s craft by pushing innovation and also helps the sales team to provide accurate CAD data to boost sales. How CAD automation helps the manufacturing industry CAD automation can dramatically improve the productivity of a manufacturing organization by automating the design process. This is an essential advantage of CAD automation. It will enable your manufacturing business to improve its productivity and increase its profits. CAD automation makes it easier for manufacturers to produce high-quality products quickly. By eliminating the need for manual processes, manufacturing teams can concentrate on developing new products and improving customer satisfaction. CAD automation allows design engineers to focus on improving the manufacturing process, enabling businesses to become more cost-efficient and innovative. Manufacturers can also reduce the number of misunderstandings and delays in the design process. Therefore, CAD automation will help manufacturers achieve speed and accuracy through correct product logic. The use of CAD automation for manufacturing can reduce the number of errors by 80% or more. CAD software is also a valuable tool for reducing costs by increasing productivity and ensuring product quality. Manufacturing engineers will be able to see the design of the products and their functionality more quickly. Using 3D modeling for design simulations will also help manufacturers anticipate any potential problems with a product. Further, CAD automation can help manufacturers reduce waste and streamline design-to-production processes. In a recent study, a UK-based stainless steel retail furniture manufacturer improved customer satisfaction by incorporating an automated furniture configurator. Using this tool, they were able to generate 100% accurate sales quotes and documents. Inventory management is another critical element for smooth production flow, as an unavailability of certain parts can put the production on hold. In addition, a lack of timely replenishment of raw materials increases lead time. How CAD automation and CPQ collaborate CAD integration with CPQ (Configure, Price, Quote) solutions can streamline the sales process and make it easier for sales representatives to customize products for customers. Previously, sales reps had to take a customer’s specifications to the engineering department, which would generate a drawing, BOM, and quote. This process could take days or even weeks. Now, CAD automation enables the sales representative to manipulate the CAD model in real-time to address customers’ requests. The customer can go to a company website and customize their products using a visual configurator. One of the primary reasons a CPQ solution is valuable is that it helps manufacturers make decisions in minutes instead of hours. Having a single product data source can prevent costly mistakes, thereby increasing customer satisfaction. CAD automation can also be used to automate the creation of standardized products. Manufacturers can send CAD models directly to the production floor by using a product configurator. With the right CPQ system, the entire process can be automated, making it easy for salespeople to generate CAD drawings within minutes. Another advantage of CPQ software is that it can help elevate the manufacturing performance of a company. Its use frees up the engineering department from constant meetings and long email chains, allowing them to focus on product development. Sales reps can also generate CAD drawings without assistance, producing realistic quotes without guesswork or special skills. Engineers can focus on higher- value tasks because the CPQ software is automated. If you’re looking for a high-quality solution for your manufacturing business, CAD automation is the perfect solution. Prescient Technologies has extensive experience working with almost all CAD platforms and creating customized CAD workflows.

Read MoreBenefits of CAD Automation

Table of content CAD automation automates repetitive tasks CAD automation automates systems integration CAD automation helps in cost-cutting CAD automation boosts collaboration CAD automation helps Sales process CAD automation reduces the time We have read what CAD automation is and its primary contribution to the entire CAD model and product development workflow. CAD automation has brought immense benefits to the manufacturing sector (refer to What is CAD Automation and its impact on Manufacturing). But to say CAD automation has brought immense benefits to the manufacturing sector is an understatement since it is increasingly hard to find a manufacturing firm without automated workflow in place. Although listing out CAD automation’s contributions is a bit hard since different players have their own success stories with this technology, here are the primary benefits that CAD automation brings to the table: CAD automation automates repetitive tasks CAD automation is a powerful tool that can save time by automating repetitive tasks and events in design. CAD Automation is a great way to free up your design engineers’ time for more productive tasks. Whether designing a new building, designing a product, or developing a system, you can automate repetitive tasks with CAD automation. The process of CAD automation helps engineers focus on higher- level tasks. Examples of CAD automation software include feature catalogs and template designs. CAD automation automates systems integration CAD integration enables engineers to create 3D designs instantly, removing the need for engineering consultation. In addition, CAD integration lets customers see a 3D model of their product without requiring the engineer’s input. This advancement is the next step in the manufacturing industry’s evolution. Automating the design process will allow companies to move the configuration process along faster and ensure the products are appropriately designed. And, with today’s faster processors and improved graphics, CAD automation is becoming more popular. CAD automation helps in cost-cutting CAD automation helps to simplify the process of designing and manufacturing products. By automating the entire design process, CAD engineers can focus on innovation and cost-cutting. Additionally, CAD automation can prevent costly mistakes that may cause delays in production and customer returns. It can also empower your engineering team to produce high-quality products faster. CAD automation also makes your business more cost-efficient and innovative. CAD automation boosts collaboration CAD automation can increase collaboration. If you have an engineering team and a sales team, CAD automation can help you make better product designs more quickly. It can help you reduce your sales costs and streamline the entire sales and engineering process. Plus, CAD automation can be used for sales and engineering, so your teams can focus on higher-value work instead of pre-sales activities. It can also help you increase your collaboration and productivity by reducing errors. CAD automation helps Sales process CAD integration can accelerate the sales process. Sales associates can customize products by referring to the CAD model. Without CAD integration, the sales associate would have to go to the engineering department and request the design they needed. Once the engineering team had the requirements, they would create a drawing, BOM, and quote. The entire process could take days. By using CAD automation, the sales associates can make custom products in a matter of hours rather than days. CAD automation reduces the time CAD automation offers many benefits. For starters, it frees up engineers’ time for more critical problem- solving tasks. With such a solution, engineers can work on their most challenging projects instead of spending hours repeating the same steps over again. Additionally, according to research, it improves employee morale and the quality of their work. You may have reasons to implement CAD automation in system workflows, but we would love to hear all of it and provide our two cents to help you automate effectively. Contact us today to know more about our offers. Prescient’s product configurators offer you complete design automation to manage your product variants.

Read MoreThe Increasing Prominence of Modularization in Mass Customization

Engineer-to-Order Modularization Industry 4.0 has driven the era of mass customization to inflated levels never seen before in manufacturing history. Accompanied by new-age technologies such as IoT, big data, 3D printing, and robotics, mass customization is executed on an unprecedented scale. Traditionally, the personalization of products was only available at a premium price. Ever since mass customization reached prominence, customers can order customized vehicles, cell phones, clothes and apparels, and even specific task- oriented machinery delivered on time. It has been possible due to the dramatic automation and modularity of workspaces that can be rapidly configured and then reconfigured to adapt to different specifications supplied by the customer. Mass customization trend is evident in both B2B and B2C sectors. Industries such as aviation, construction, glass, and ceramic manufacturing have adopted mass customization with a particular emphasis on 3D printing to a great extent. An exciting aspect of mass customization is lean customization, a just-in-time (JIT) inventory system, and digital tech to produce items with lesser costs. Lean customization allows consumers to select their preferred designs and colors at no extra cost to the company. Since lean customization involves a specific batchwise production process, it can be implemented in the well-known crafting specialty strategy known as Engineer-to-order. Engineer-to-Order Engineer-to-order means craftsmanship where production is tailored for specific customer requirements. It means the entire research and development, design, and build is suited for certain specifications, and it differs from customer to customer. Although such productions offer a great deal of personalized content to the customers, it comes with reasonable operational costs, making the product quite expensive. So, the prime goal is to reduce operating costs which will reflect on the product’s price. Incorporating lean customization into engineer-to-order addresses this issue, getting modular work processes. Modularization About 100 years ago, Henry Ford presented the first assembly line to the automotive industry. Since then, auto manufacturing has primarily been in a fixed and sequenced line, operated by pre-defined and rigid processes. Once an assembly line is defined for a specific model, it cannot be modified throughout the entire product’s lifecycle and commands over the intra-logistical methods of the production and supply chain. The auto manufacturers had to incur huge costs if they wanted to release a modified model since it involved creating an entirely different assembly line. This issue is not limited to car manufacturing but also apparel, chemical, and pharma industries. To address an agile and flexible production process, the industry is using the concept of modularization. Modularity essentially refers to the capability of a system to be reconfigured on a plug-n-play basis, thereby allowing it to respond to changes in customer requirements quickly and efficiently. Audi is one such company that has created independent workstations, each assigned a particular production function. Unfinished cars move autonomously from one workstation to the other, with the help of driverless transport systems (DTS), where connected robots and a few humans assemble a particular part of the car. Suppose one DTS reaches a station that is already occupied. In that case, it is programmed to head to another available station, thereby removing the delays part of the conventional assembly line. This modular assembly also allows for changes to be made on the go. The key advantages of modularization include: Modularization involves taking in requirements and specifications from customers and passing them off to the production floor directly without any significant engineering maneuver in between. Thus, it needs a rule-driven production that regulates how modularization is successfully achieved. To enforce a well- functioning and effective rules-driven production system, manufacturers can take these three steps: Modularization is the key to unlocking mass customization. By breaking down a product into smaller, more manageable parts, it becomes easier and faster to produce customized versions of that product. It also becomes more cost-effective, as each individual component can be produced in larger quantities. It is good news for consumers who want unique products without paying a premium price and for businesses who want to offer those unique products without breaking the bank.

Read MoreCombine Product Digital Twin and Product Configurator for Faster Product

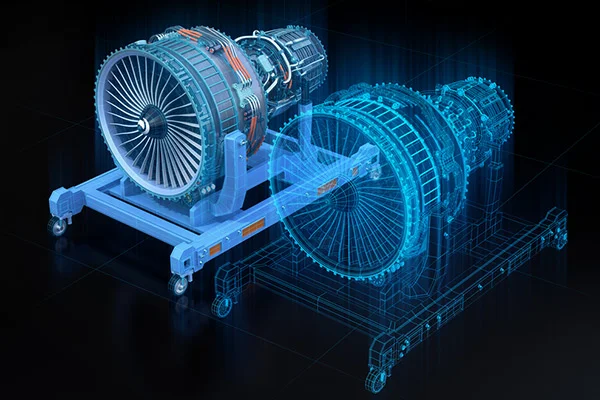

By Swanand Javadekar A digital twin is a dynamic representation of an asset that allows us to understand the better working of the system and predict performance for better design directions. A product configurator is a dynamic representation of the CAD model that allows us to build an intelligent, practical model to enhance the speed of design and development. This paper conceives the concept and applies it to functional scenarios for better understanding and elaboration. Let us quickly elaborate on both the concepts and explore further for combined application: Product Configurator Product Configurator is a single solution that can, Essentially, it’s a solution that helps you get more customers and dramatically increases the productivity of your sales and design team. A product configurator is a design automation solution that works on parameter-driven design. We can create a complete model on the fly by entering a few key parameters. Our Product Configurator solution is based on proven and tested CAD neutral architecture. Hence we can work with the CAD system you use (NX, SolidEdge, SolidWorks, Creo (Pro/E), AutoCAD, Autodesk Inventor, and others). Digital Twin As mentioned earlier, a digital twin is a virtual representation of an actual world entity or a system to understand product behavior better. Generally, we can divide digital twin into three categories: Case Study: Industrial Engineering (Elevator) The product configurator and the digital twin have applications at various levels, typically in operations, commissioning, and installations. If we divide elevator methods and processes into three categories: Install, Operate, Maintain, we will elaborate areas where the standard approach will be helpful. Product configurator can be used to build a CAD model based on available configuration parameters such as allotted space, cage parameters, and internal and external dimensions. The cad model will be ready based upon various options, which can be easily used further for manufacturing drawings or product validation. Once your multiple models are available, the same can be used for further meshing and validation to pick the best-suited configuration. We can calculate the remaining useful life (RUL) and any what-if scenario. With confirmation from the product validation exercise, the final model can be used for further AR/VR exercise for product visualization purposes. Product configurator and digital twin combination will provide faster product development; the final product can also be used for further downstream applications such as AR/VR. Not only does the product manufacturer benefit by delivering a superior product, but other supporting systems such as building, and infrastructure management will benefit from the optimized maintenance cost and less downtime. Case Study: Industrial Engineering (Furniture) The furniture industry is an exciting example involving engineering with style and substance. The customer is demanding in terms of various options or variants, and the possibilities are endless. It’s where science meets the art, and probabilities are limitless. If we take the example of a simple chair, the flow chart is quite exhaustive: Type Base Features executive 5-star base high back conference 4-star base low back dining wood leg headrest auditorium sled base tablet soft stools stackable meeting swivel visitor adjustable plain sitting All the combinations come with the additional complexity of colors, mesh size, etc. In such a case where the manufacturer provides exhaustive options, and customers make customizable chairs, a combination of Product configurator and digital twin offers dynamic support to realize the dream. The CAD model of a chair combination is made faster while tested with the furniture industry-standard of weights. Any unique composite structure design or material changes can also be realized quickly. It allows the manufacturer to release the product faster to customer delight. Combining Product configurator and digital twin is the way forward as it allows manufacturers to manufacture faster to market methodology and offers customers to choose from a wide variety of options leading to customer delight.

Read MorePoint Clouds | Point cloud formats and issues

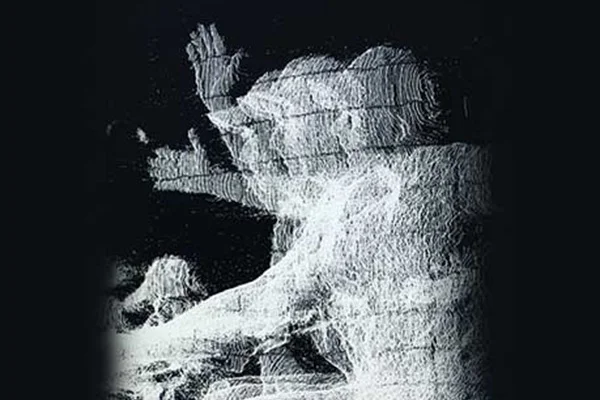

Table of content Different 3D point cloud file formats Challenges with point cloud data Whether working on a renovation project or making information data about an as-built situation, it is understandable that the amount of time and energy spent analyzing the object/project can be pretty debilitating. Technical literature over the years has come up with several methods to make a precise approach. But inarguably, the most prominent method is the application of Point Clouds. 3D scanners gather point measurements from real-world objects or photos for a point cloud that can be translated to a 3D mesh or CAD model. But what is a Point Cloud? A standard definition of point clouds would be – A point cloud collection of data points defined by a given coordinates system. In a 3D coordinates system, for example, a point cloud may determine the shape of some real or created physical system. Point clouds are used to create 3D meshes and other models used in 3D modeling for various fields, including medical imaging, architecture, 3D printing, manufacturing, 3D gaming, and various virtual reality (VR) applications. When taken together, a point is identified by three coordinates that correlate to a precise point in space relative to the end of origin. Different 3D point cloud file formats Scanning a space or an object and bringing it into designated software lets us manipulate the scans further, and stitch them together, which can be exported to be converted into a 3D model. Now there are numerous file formats for 3D modeling. Different scanners yield raw data in different formats. One needs other processing software for such files, and each & every software has its exporting capabilities. Most software systems are designed to receive a large number of file formats and have flexible export options. This section will walk you through some known and commonly used file formats. Securing the data in these common formats enables using different software for processing without approaching a third-party converter. Standard point cloud file formatsOBJ: It is a simple data format that only represents 3D geometry, color, and texture. And this format has been adopted by a wide range of 3D graphics applications. It is commonly ASCII (American Standard Code for Information Interchange). ASCII is a rooted language based on a binary that conveys information using text. Standard ASCII represents each character as a 7-bit binary number. In reverse engineering, characters are the focus of data. E57: E57 is a compact and widely used open, vendor-neutral file format for point clouds, and it can also be used to store images and data produced by laser scanners and other 3D imaging systems. Its compact, binary-based format combines the speed and accessibility of ASCII with the precision and accuracy of binary. E57 files can also represent normals, colors, and scalar field intensity. However, E57 is not universally compatible across all software platforms. PLY: The full form of PLY is the polygon file format. PLY was built to store 3D data. It uses lists of nominally flat polygons to represent objects. The aim is to store a more significant number of physical elements. It makes the file format capable of representing transparency, color, texture, coordinates, and data confidence values. It is found in ASCII and binary versions. PTS, PTX & XYZ: These three formats are familiar and compatible with most BIM software. It conveys data in lines of text. They can be easily converted and manipulated. PCG, RCS & RCP: These three formats were developed by Autodesk to meet their software suite’s demands. RCS and RCP are relatively newer. Binary point cloud file formats are better than ASCII or repurposed file types. It is because the latter is more universal and has better long-term storage capabilities. However, this type of format can be used to create a backup of the original data. If you need to convert binary point cloud files to ASCII, back up your binary files before reformatting them. This way, you can restore your data if something goes wrong. Challenges with point cloud data In reverse engineering, you may encounter several Point Cloud issues. The laser scanning procedure has catapulted product design technology to new heights. 3D data capturing system has come a long way, and we can see where it’s headed. As more and more professionals and end users are using new devices, the scanner market is rising at a quick pace. But along with a positive market change, handling and controlling the data available becomes a vital issue. These problems can result in poor quality point cloud data. Read on to learn more about five key challenges professionals working with point cloud face are: Data Quality: You must identify the quality issues in reverse engineering point cloud data. Reconstruction algorithms differ in their behavior based on the properties of point clouds. Many studies have classified the properties of point clouds by their effect on algorithms. The quality of point clouds affects the precision of the reconstructions. Point clouds produced by body scanners typically contain many duplicated and overlapping patches. These features cause a large amount of noise and redundancy in the final data. Reconstruction of free-form surfaces requires the use of clean-up meshes. This data must be transformed into a model that is consistent and accurate. Fortunately, this task is possible with the help of cloud-to-cloud alignment tools. Data Format: New devices out there in the market yield back data in a new form. Often, one needs to bring together data in different formats from different devices against a compatible software tool. It presents a not-so-easy situation. Identifying the wrong point cloud file format in reverse engineering is of great importance. Often when a company attempts to perform reverse engineering, it will be presented with a point cloud file in the wrong format. It can cause problems because the data is not in the correct format. EMPA has made it their business to work with point clouds as soon as possible. However, this doesn’t mean that you should give up

Read MoreThe perks of Electronic Product Catalog

The perks of Electronic Product Catalog An electronic product catalog is a comprehensive list of all your products in a digital publication. Unlike paper catalogs, electronic product catalogs are easier to navigate and maintain regularly. The primary objective of the electronic product catalog is to facilitate product availability and information to customers, thereby pushing sales. In Computer-Aided Design (CAD), such a digital product catalog consists of a list of CAD products readily available to the customers and other prospects. An increasing number of companies resort to electronic product catalogs with information about CAD products available to their customers and prospects. The reason behind this points towards a handful of benefits that electronic product catalogs bring, they are as follows: An excellent electronic product catalog requires some planning and decisions to be perfect for your requirement. Here are the few areas you need to consider and make decisions on: The Product: The first and foremost task is to decide which products you wish to include in the catalog and how you wish to portray them. You may have dozens or even hundreds of products in your portfolio. You could apply the 80-20 rule and decide on a set of products that gives you maximum coverage. Remember to not flood a single page with the bulk of your products, as that kills the purpose of a smooth customer experience. It would help if you also determined how you group your products. Righ grouping results in a better surfing experience. The Platform: Choose the preferred platform to house your product catalog. The most obvious choice is to make it available on your website. However, you could choose to make a Phone App or create a DVD (if you have a vast number of products). You can also go for a host website that works solely to monitor and maintain your catalog. A particular advantage of host websites is their inventory of pre-existing design features, tools, and templates. It saves a lot of brainstorming. The Data format: Decide what data you wish to make available. You can have a plethora of data, and including all of them will mess up your platform. Visual appeal is a must, and you must carefully decide which one to prefer, be it 2D data vs. 3D data, GA or schematic vs. to the scale drawings, dumb 3D models vs. parametric models, etc. The Technology: At a high level, there are two main approaches to solving this: Pre-Cooked and On- The-Fly. In the Pre-Cooked method, data for all configurations of your products are kept in the repository and are delivered on-demand. This option is suitable if your products’ unique configurations are on the lower side, say up to a few hundred. The On-The-Fly method generates the necessary data in real-time using specific master models. It can very easily handle any number of unique product configurations that you may have. Pricing and tax: Pricing and hidden tax rates are crucial if you want a business-friendly e-catalog. You have to decide the price of your products, and they need to be market-specific. Tax and other charges (shipping charges) contribute to the overall cost of a product, and you must make sure they are reflected under the product description or payment gateway. Links and CTAs: Electronic product catalogs work best with links inside. Links are a great way to point buyers to your shop. Alongside links, we have call-to-action (CTA) buttons short text on buttons prompting the customer to take the next step. CTA buttons alongside links are an excellent tool to boost sales. So it is up to you to decide how you want to enhance your catalog. Search Engine Optimization (SEO): Since your e-catalog will be published online for the public to see, you need a robust SEO strategy to ensure your catalog platform is readily available in the search engines. For that, you will need marketing SEO expertise to help you go through SEO objectives. Electronic product catalogs are a fantastic way to showcase your inventory and make sales. Make sure you have ticked off all the necessary do’s and dont’s before launching your e-catalog.

Read MoreMass Customization: Why “built-to-order” is a healthy step for your business

Product Configurators Mass Customization as a brilliant strategy Nowadays, there is a trend where businesses and consumers opt for more personalized products and services. When scaled appropriately, this trend, called Mass Customization, combines the Customization and flexibility of built-to-order products with low production costs. Mass Customization is the practice of providing products and services built or modified as per a customer’s requirements. In other words, mass Customization involves your blueprint mixed with a professional’s expertise and necessary tools to make the perfect product of your desire, which is uniquely yours. Mass Customization is also called built-to-order or made-to-order. Mass Customization facilitates customized product features while keeping in sync with low unit costs of mass production. Sometimes, mass Customization also involves the modularity of product components. Such flexibility allows effective mix-and-match to build a customized final commodity. Mass Customization has been well adopted in retail, software development, financial services & fintech, and modular home builders. Utilizing such business practices provides an edge over your competitors. With every individual looking for a custom product designed especially for them, more and more companies are now offering Mass Customization to satisfy the needs of their customers. In his book, Mass Customization: The New Frontier in Business Competition, B. Joseph Pine II talks about four mass customization types. They are: CollaborativeCustomization AdaptiveCustomization TransparentCustomization CosmeticCustomization companies collaborate with customers to offer products uniquely crafted to each client companies deliver products based on one standard but customizable by the end-user companies provide personalized products to individual clients without overtly disclosing that they are customized companies build single standard products but deliver them in different ways as per other customer demands Works great in fashion, apparel, & retail businesses It fits good in the lighting, luxury bath fittings sector E-commerce brands and OTT platforms are good examples Applies to textile, food & beverage industry Product Configurators In CAD software development and services, mass Customization is achieved by using web-based tools like Product Configurators which achieves Customization yet results in savings in cost. Software developers apply personalized product configurators that allow end-users to add, change, modify, or tweak certain features & functions of a core product. Don’t miss out your chance to have a customized product configurator today Prescient Technology’s robust IT team can build personalized configurators specifically curated for your business needs. If you have any query, feel free to get in touch with us today. From the top of the pyramid, mass customization can be categorized into two broad areas: Since mass Customization essentially means offering customers according to their orders rather than generic products, it creates a massive differentiator in the minds of both B2B and B2C customers. Let us have a look at how built-to-order personalization works: Configure: The Product Configurators present a simple user interface for customers to try out various options by changing parameters and selecting different options to suit their specific requirements. Once they are satisfied, they can often preview their selections in the form of a 3D model. Instant Quote: The quote generation system is linked to the Product Configurator, helping customers with instant quotes for the selections that they make. Ready to Manufacture: The Product Configurator can generate all the details like manufacturing drawings required by the manufacturing/assembly team without manual intervention. Such innovative manufacturing processes enable the production of interchangeable parts that can be shuffled differently to build a cost-effective product that fulfills client requirements. The levels of automation depend on the complexity of the product and the nature of the sales cycle. It can be autonomous for simple products (typically B2C), and for complex products (typically B2B), it can be semi-autonomous. Even for B2B products, the semi-automatic process dramatically improves the productivity of the sales team and the design team. Product configurators are found at a B2B level across diverse industries ranging from Cranes & Hoists, Material Handling and Storage, Pumps, Valves, Bearings, etc. The benefits are: At a B2C level, product configurators are found across various sectors like laptops, apparel, shoes, jewelry, houses, furniture, etc. The benefits are: Mass Customization as a brilliant strategy There is a term known as “product differentiation,” and mass customization allows manufacturers to postpone product differentiation till the end phase of manufacturing. Customized features are more likely to engage consumers since they get to make many decisions about the operation and makeup. The ability to tweak a product based on personal preference has a high possibility of swinging a client’s choice towards what you have to offer than your competitor. Mass Customization also helps you with excess inventory expenses. A JIT (just-in-time) approach can prevent flooding of inventory unnecessarily. Mass Customization can be used as a part of a marketing strategy where your ability to produce personalized products or provide tailor-made services at a market standard price is used as a lucrative branding of your product. If there is no compromise on quality, on-time delivery, you have a good chance of driving sales, churning profits, and attracting customer loyalty. Prescient Technologes has hands-on experience in creating client-centric, on-demand product config and software solutions and we will be glad to assist you with your needs or queries.

Read More