Point Clouds | Point cloud formats and issues

Table of content Different 3D point cloud file formats Challenges with point cloud data Whether working on a renovation project or making information data about an as-built situation, it is understandable that the amount of time and energy spent analyzing the object/project can be pretty debilitating. Technical literature over the years has come up with several methods to make a precise approach. But inarguably, the most prominent method is the application of Point Clouds. 3D scanners gather point measurements from real-world objects or photos for a point cloud that can be translated to a 3D mesh or CAD model. But what is a Point Cloud? A standard definition of point clouds would be – A point cloud collection of data points defined by a given coordinates system. In a 3D coordinates system, for example, a point cloud may determine the shape of some real or created physical system. Point clouds are used to create 3D meshes and other models used in 3D modeling for various fields, including medical imaging, architecture, 3D printing, manufacturing, 3D gaming, and various virtual reality (VR) applications. When taken together, a point is identified by three coordinates that correlate to a precise point in space relative to the end of origin. Different 3D point cloud file formats Scanning a space or an object and bringing it into designated software lets us manipulate the scans further, and stitch them together, which can be exported to be converted into a 3D model. Now there are numerous file formats for 3D modeling. Different scanners yield raw data in different formats. One needs other processing software for such files, and each & every software has its exporting capabilities. Most software systems are designed to receive a large number of file formats and have flexible export options. This section will walk you through some known and commonly used file formats. Securing the data in these common formats enables using different software for processing without approaching a third-party converter. Standard point cloud file formatsOBJ: It is a simple data format that only represents 3D geometry, color, and texture. And this format has been adopted by a wide range of 3D graphics applications. It is commonly ASCII (American Standard Code for Information Interchange). ASCII is a rooted language based on a binary that conveys information using text. Standard ASCII represents each character as a 7-bit binary number. In reverse engineering, characters are the focus of data. E57: E57 is a compact and widely used open, vendor-neutral file format for point clouds, and it can also be used to store images and data produced by laser scanners and other 3D imaging systems. Its compact, binary-based format combines the speed and accessibility of ASCII with the precision and accuracy of binary. E57 files can also represent normals, colors, and scalar field intensity. However, E57 is not universally compatible across all software platforms. PLY: The full form of PLY is the polygon file format. PLY was built to store 3D data. It uses lists of nominally flat polygons to represent objects. The aim is to store a more significant number of physical elements. It makes the file format capable of representing transparency, color, texture, coordinates, and data confidence values. It is found in ASCII and binary versions. PTS, PTX & XYZ: These three formats are familiar and compatible with most BIM software. It conveys data in lines of text. They can be easily converted and manipulated. PCG, RCS & RCP: These three formats were developed by Autodesk to meet their software suite’s demands. RCS and RCP are relatively newer. Binary point cloud file formats are better than ASCII or repurposed file types. It is because the latter is more universal and has better long-term storage capabilities. However, this type of format can be used to create a backup of the original data. If you need to convert binary point cloud files to ASCII, back up your binary files before reformatting them. This way, you can restore your data if something goes wrong. Challenges with point cloud data In reverse engineering, you may encounter several Point Cloud issues. The laser scanning procedure has catapulted product design technology to new heights. 3D data capturing system has come a long way, and we can see where it’s headed. As more and more professionals and end users are using new devices, the scanner market is rising at a quick pace. But along with a positive market change, handling and controlling the data available becomes a vital issue. These problems can result in poor quality point cloud data. Read on to learn more about five key challenges professionals working with point cloud face are: Data Quality: You must identify the quality issues in reverse engineering point cloud data. Reconstruction algorithms differ in their behavior based on the properties of point clouds. Many studies have classified the properties of point clouds by their effect on algorithms. The quality of point clouds affects the precision of the reconstructions. Point clouds produced by body scanners typically contain many duplicated and overlapping patches. These features cause a large amount of noise and redundancy in the final data. Reconstruction of free-form surfaces requires the use of clean-up meshes. This data must be transformed into a model that is consistent and accurate. Fortunately, this task is possible with the help of cloud-to-cloud alignment tools. Data Format: New devices out there in the market yield back data in a new form. Often, one needs to bring together data in different formats from different devices against a compatible software tool. It presents a not-so-easy situation. Identifying the wrong point cloud file format in reverse engineering is of great importance. Often when a company attempts to perform reverse engineering, it will be presented with a point cloud file in the wrong format. It can cause problems because the data is not in the correct format. EMPA has made it their business to work with point clouds as soon as possible. However, this doesn’t mean that you should give up

Read MoreTypes & Benefits of 3D Scanners and 3D Scanning Technologies

Table of content 3D Scanning Technology Types of scanners Benefits of 3D Laser Scanners As we have seen during the introduction, the first step to reverse engineering a product is through scanning with the help of 3D scanners. Early eras have seen the painstaking task of obtaining dimensions of an existing product. These methods were time-consuming and needed attention to detail from the first stage. However, with the rapid development in the scanning technology, the inception of a product has caught speed, and the chances of errors have reduced dramatically, making 3D scanning and measurement a vital part, starting from the design stage to the inspection stage. 3D laser scanning is the technology to capture a physical object’s exact size and shape using a laser beam to create a digital 3-dimensional representation of the same. 3D laser scanners produce “point clouds” of data from the surface of an object. 3D Scanning Technology 3D laser scanning efficiently takes the measurements of contoured surfaces and complex geometries, requiring vast amounts of data for accurate description. Doing this using traditional measurement methods is impractical and time-consuming. Acquiring sizes and dimensions of free-form shapes creates precise point cloud data. The basic working principle of a 3D scanner is to collect an entity’s data. It can either be:an object In reverse engineering, a laser scanner’s primary aim is to provide a lot of information about the design of an object which in the later stages gets converted to 3D CAD models, considering the compatibility of 3D scans and Computer Aided Design (CAD) software. 3D scans are even compatible with 3D printing, requiring specific computer software.3D scanning technologies vary with different physical principles and can be classified as follows:Laser triangulation 3D scanning technology: In this category, the laser scanner projects a laser beam on a surface and measures the deformation of the laser ray. Structured light 3D scanning technology: This technology involves projecting structured patterns of light on an object and acquiring a surface’s shape by measuring the light pattern’s deformation. Photogrammetric technology: It is also known as a 3D scan from photography. It reconstructs an object from 2D to 3D and has specific computational geometrical algorithms for the task. Photogrammetry is cheap, precise, and used to scan large objects such as buildings and stadiums.Photogrammetric technology Laser pulse 3D scanning technology: This unique process collects geometrical information by evaluating the time a laser beam takes to travel between its emission and reception. Computerized Tomography (CT scan): A widely used technique in the medical sector, CT scan is generally used to scan images of the human interiors. CT scans consist of scanning a part and taking a series of 2D images of various sections with X-rays. The 2D images are later superimposed on each other to imitate a 3D model. Contact-based 3D scanning technology: This process requires contact between the probe and the object, where the probe is moved firmly over the surface to acquire data. Types of scanners Apart from scanning technologies, there are various types of 3D scanners. Some are built for short- range scanning, while others are ideal for medium or long-range scanning. The building and usage of specific scanners hugely depend upon the object’s size to be scanned. The scanners for measuring small things vastly differ from those used for large-bodied objects, such as ships. Here is a summary of the types of 3D laser Scanners: Short Range 3D scanners: Short Range 3D scanners utilize either a Laser triangulation technology or Structured Light technology. Laser-based 3D scanners: These scanners employ trigonometric triangulation to capture a 3D object as millions of points. Laser scanners work by projecting a laser beam or multiple laser beams on an object and capturing its reflection with sensors located at a fixed distance from the scanners. Laser scanners come in various designs such as handheld portable units, arm-based, CMM-based, long-range, and single-point long-range trackers. Structured light 3D scanners: These are also known as white light scanners. However, most structured scanners use blue or white LED lights. The light pattern usually consists of a geometrical shape such as a bar, block, or other shape projected onto the object. The sensors consider the edge of the pattern to determine the 3D shape of the object. Blue or white light scanners are generally used to obtain outward dimensions. Medium and Long range scanners: Long-range 3D scanners are used for large objects such as buildings, ships, aircraft, and military vehicles. These scanners rotate and spin a mirror which reflects the laser outward towards the thing or areas to be 3D scanned. Arm-based scanners: Arm-based scanners are handy when measuring small minor parts, as they can be maneuvered by attaching them to the arm and is generally portable. Benefits of 3D Laser Scanners 3D scanners have contributed a lot over the years; needless to say; they come up with many benefits. Some of them are as follows:Able to scan harsh surfaces, such as shiny or dark finishes.This is strictly for handheld or other portable scanners. But given their importance, it is safe to say that the portability of scanners has played a significant role in easing up engineering.The scanning technology has enabled it to capture millions of points in less time.Scanners are less sensitive to changing light conditions and ambient light.Scanning of complex contours and geometrical figures has become more convenient with the invention of groundbreaking scanning technologies.Laser scanners have become so diverse that they are produced depending upon various projects or the objects to be scanned. The right place for your reverse engineering solutions Whether it is scanning or point cloud generation or meshing or 3D model creation, our engineers have been thoroughly trained in end-to-end reverse engineering.

Read MoreWhat is CAD | Types of CAD Models and CAD Formats

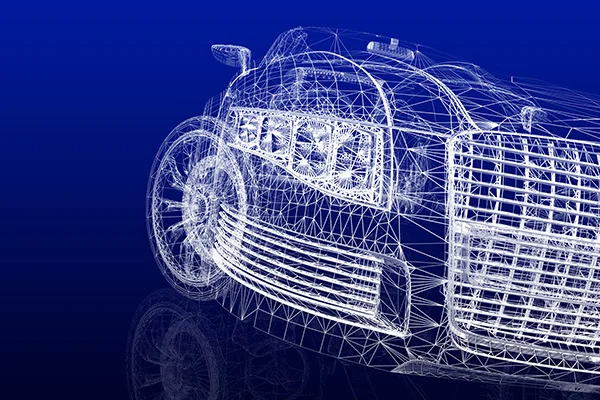

Table of content What is CAD? Types of CAD models Types of CAD formats Use of CAD What is CAD? Computer-Aided Design, aka CAD, is undoubtedly a crucial stage in product development. By definition, CAD is the acronym for Computer-Aided Design. It covers various design tools used by multiple professionals like artists, game designers, manufacturers, and design engineers. After a meshed part is aligned, it goes through surface modeling in tools such as Polyworks. It generates a non-parametric model (IGES or STEP format) or parametric modeling where a sketch of the meshed part is created instead of putting it through surfacing (.PRT format). The resultant is generally called a 3D computer-aided model or CAD model. The technology of CAD systems has tremendously helped users by performing thousands of complex geometrical calculations in the background without anyone dropping a sweat for it. CAD has its origin in early 2D drawings where one could draw objects using basic views: top, bottom, left, right, front, back, and the angled isometric view. 3D CAD programs allow users to take 2D pictures and convert them into a 3D object on the screen. In a simple definition, CAD design is converting primary design data into a more perceptible and more understandable design. Each CAD system has its algorithm for describing geometry mathematically and structurally. Types of CAD models. Everything comes with its variety, and CAD modeling is no stranger. As the technology evolved, CAD modeling came up in different styles. There are many methods of classifying them, but a broad general classification can be as follows: Two-dimensional or 2D CAD: The early version of CAD that most of us are aware of. These are 2-dimensional drawings on a flat sheet with dimensions, layouts, and other information needed to manufacture the object. The 2D CAD objects consist of lines, ovals, circles, ovals, curves, and slots. 2D CAD platforms generally come with a library of geometric images and the ability to create Bezier curves, polylines, and splines. They are also capable of generating a bill of materials (BOM). 2.5D CAD:The 2.5 D CAD are prismatic, which means they represent the depth of an object. They fall between 2D and 3D CAD, and the objects consist of geometric patterns like in 2D CAD. Three-dimensional or 3D CAD:The purpose of both 2D and 3D models is the same. But what sets 3D models apart is their ability to present more excellent details about the individual component and assembly by projecting it as a full-scale 3-dimensional object. 3D CAD offers a realistic portrayal of the CAD model. 3D models can be viewed and rotated in X, Y, or Z axes. It also shows how two objects can fit and operate, which is impossible with 2D CAD. 3D models can be further classified into three categories: 3D Wire-frame Models:These models resemble an entire object made of just wires, with the background visible through the skeletal structure. Surface Models:Surface models are the next stage of wireframe models, and they are created by joining the 3D surfaces together and look like real-life objects. Solid Models:They best represent real physical objects in a virtual environment. Unlike other models, solid models have weight, volume, and density properties. They are the most used models and serve as prototypes for engineering projects. The Boundary Representation (BREP) solid modeling links Constructive Solid Geometry (CSG) images while a hybrid systems mix CSG and BREP to attain the intended design. Types of CAD formats Different professionals use different software platforms for various reasons like cost, project requirements, features, etc. Although the software comes with its file formats, there are instances where one needs to share their project with someone else, either partners or clients, who are using different software. In such cases, it is necessary that both parties’ software understand each other’s file formats or, in other words, interoperable. As a result of this situation, it is essential to have file formats that can be accommodated in various software. CAD file formats can be broadly classified into two types: STEP: This is the most popular CAD file format of all. It is widely used and highly recommended as most software support STEP files. STEP is the acronym for Standard for the Exchange of Product Data. IGES: IGES is the acronym for Initial Graphics Exchange Specification. It is an old CAD file format that is vendor-neutral. IGES has fallen out lately since it lacks many features that newer file formats have. Parasolid: Parasolid was initially developed by Shape Data and is currently owned by Siemens PLM Software. STL: STL stands for Stereolithography which is the format for 3D information created by 3D systems. STL finds its usage mostly in 3D printers. STL describes only the outer structure or surface geometry of a physical object but doesn’t give out the color, texture, and other attributes of an object. VRML: VRML stands for Virtual Reality Modeling Language. Although it gives back more attributes than STL, a handful of software can read it. Prototyping & pilot runs (preliminary design stage) In this stage, prototypes are built and tested after several iterations, and a pilot run of the manufacturing process is conducted. This stage involves creating rapid prototypes for a concept deemed to have business relevance and value. Prototype means a ‘quick and dirty’ model rather than a refined one that will be tested and marketed later. Adjustments are carried out as required before finalizing the design. X3D: X3D is an XML-based file format for representing 3D computer graphics. COLLADA: COLLADA stands for Collaborative Design Activity and is mostly used in gaming and 3D modeling. DXF: DXF stands for Drawing Exchange Format, a pure 2D file format native to AutoCAD. Use of CAD CAD technology has placed the entire engineering process in an adrenaline mode. It is possible to mold or fold, modify, or make a new part from scratch, all with the help of CAD modeling software. The many uses of CAD are as follows:CAD generates design and layouts, details and calculations, and 3-D

Read MoreMesh Generation Algorithms

Table of content FAQs Algorithm methods for Quadrilateral or Hexahedral Mesh Algorithm methods for Triangular and Tetrahedral Mesh Mesh is the various aspects upon which a mesh can be classified. Mesh generation requires expertise in the areas of meshing algorithms, geometric design, computational geometry, computational physics, numerical analysis, scientific visualization, and software engineering to create a mesh tool. FAQs Over the years, mesh generation technology has evolved shoulder to shoulder with increasing hardware capability. Even with fully automatic mesh generators, there are many cases where the solution time is less than the meshing time. Meshing can be used for a wide array of applications; however, the principal application of interest is the finite element method. Surface domains are divided into triangular or quadrilateral elements, while volume domain is divided mainly into tetrahedral or hexahedral elements. A meshing algorithm can ideally define the shape and distribution of the elements. A vital step of the finite element method for numerical computation is mesh generation algorithms. A given domain is to be partitioned into simpler ‘elements.’ There should be a few elements, but some domain portions may need small elements to make the computation more accurate. All elements should be ‘well-shaped.’ Let us walk through different meshing algorithms based on two common domains: quadrilateral/hexahedral mesh and triangle/tetrahedral mesh. Algorithm methods for Quadrilateral or Hexahedral Mesh Grid-Based MethodThe grid-based method involves the following steps: Medial Axis MethodThe medial axis method involves an initial decomposition of the volumes. The technique involves a few steps as given below: Plastering methodPlastering is the process in which elements are placed, starting with the boundaries and advancing towards the center of the volume. The steps of this method are as follows: Whisker Weaving MethodWhisker weaving is based on the spatial twist continuum (STC) concept. The STC is the dual of the hexahedral mesh, represented by an arrangement of intersecting surfaces that bisects hexahedral elements in each direction. The whisker weaving algorithm can be explained in the following steps: Paving MethodThe paving method has the following steps to generate a quadrilateral mesh: Mapping Mesh MethodThe Mapped method for quad mesh generation involves the following steps: Algorithm methods for Triangular and Tetrahedral MeshQuadtree Mesh MethodThe quadtree mesh method recursively subdivided a square containing the geometric model until the desired resolution is reached. The steps for two-dimensional quadtree decomposition of a model are as follows: Delaunay Triangulation MethodA Delaunay triangulation for a set P of discrete points in the plane is a triangulation DT such that no points in P are inside the circum-circle of any triangles in DT. The steps of construction Delaunay triangulation are as follows: Delaunay Triangulation maximizes the minimum angle of all the triangle angles and tends to avoid skinny triangles. Advancing Front MethodAnother famous family of triangular and tetrahedral mesh generation algorithms is the advancing front or moving front method. The mesh generation process is explained in the following steps: Spatial Decomposition MethodThe steps for the spatial decomposition method are as follows: Sphere Packing MethodThe sphere packing method follows the given steps: Get access to our mesh tools library today Mesh Tools library offers a comprehensive set of operation for meshes for all your needs. Developed in C++, this library can be easily integrated in to your product. To learn more,

Read MoreMesh Quality

The quality of a mesh plays a significant role in the accuracy and stability of the numerical computation. Regardless of the type of mesh used in your domain, checking the quality of your mesh is a must. The ‘good meshes’ are the ones that produce results with fairly acceptable level of accuracy, considering that all other inputs to the model are accurate. While evaluating whether the quality of the mesh is sufficient for the problem under modeling, it is important to consider attributes such as mesh element distribution, cell shape, smoothness, and flow-field dependency. Element Distribution It is known that meshes are made of elements (vertices, edges and faces). The extent, to which the noticeable features such as shear layers, separated regions, shock waves, boundary layers, and mixing zones are resolved, relies on the density and distribution of mesh elements. In certain cases, critical regions with poor resolution can dramatically affect results. For example, the prediction of separation due to an adverse pressure gradient depends heavily on the resolution of the boundary layer upstream of the point of separation. Cell Quality The quality of a cell has a crucial impact on the accuracy of the entire mesh. The quality of cell is analyzed by the virtue of three aspects: Orthogonal quality, Aspect ratio and Skewness. Orthogonal Quality: An important indicator of mesh quality is an entity referred to as the orthogonal quality. The worst cells will have an orthogonal quality close to 0 and the best cells will have an orthogonal quality closer to 1. Aspect Ratio: Aspect ratio is an important indicator of mesh quality. It is a measure of stretching of the cell. It is computed as the ratio of the maximum value to the minimum value of any of the following distances: the normal distances between the cell centroid and face centroids and the distances between the cell centroid and nodes. Skewness: Skewness can be defined as the difference between the shape of the cell and the shape of an equilateral cell of equivalent volume. Highly skewed cells can decrease accuracy and destabilize the solution. Smoothness Smoothness redirects to truncation error which is the difference between the partial derivatives in the equations and their discrete approximations. Rapid changes in cell volume between adjacent cells results in larger truncation errors. Smoothness can be improved by refining the mesh based on the change in cell volume or the gradient of cell volume. Flow-Field Dependency The entire effects of resolution, smoothness, and cell shape on the accuracy and stability of the solution process is dependent upon the flow field being simulated. For example, skewed cells can be acceptable in benign flow regions, but they can be very damaging in regions with strong flow gradients. Correct Mesh Size Mesh size stands out as one of the most common problems to an equation. The bigger elements yield bad results. On the other hand, smaller elements make computing so long that it takes a long amount of time to get any result. One might never really know where exactly is the mesh size is on the scale. It is important to consider chosen analysis for different mesh sizes. As smaller mesh means a significant amount of computing time, it is important to strike a balance between computing time and accuracy. Too coarse mesh leads to erroneous results. In places where big deformations/stresses/instabilities take place, reducing element sizes allow for greatly increased accuracy without great expense in computing time.

Read More