Types of Jigs and Fixtures

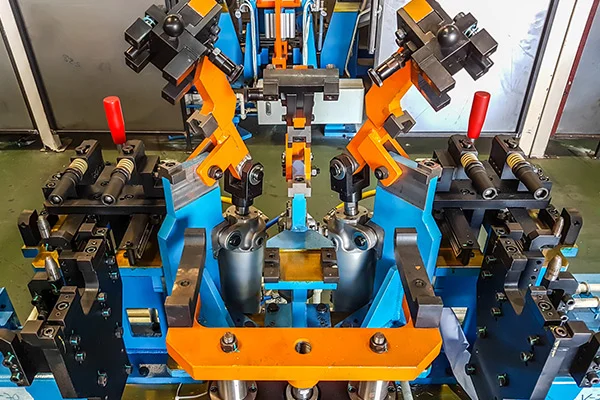

Table of content Types of Jigs Types of Fixtures We know that jigs and fixtures are the devices that help in the machining of jobs and reduce the human efforts required for producing these parts. It has been explained why a center lathe is an ideal machine tool for creating individual pieces of different shapes and sizes. Still, for manufacturing similar objects in high numbers, its use is not economical. Different objects may require drilling, milling, planing, grinding machines, etc. Specific tools are necessary for producing these objects in identical shapes and sizes on a mass scale by holding and locating tasks to minimize the repetition work. That is when various types of jigs and fixtures come into play. Considering the variety in the nature of jobs to be machined, the quality, and the associated functions, the type of jig and fixture varies. Following are the various kinds of jigs and fixtures. Types of Jigs Template Jig: The template jig is the simplest of all the models. The plate, having two holes, acts as a template fixed on the component to be machined. The drill is guided through these template holes, and the required holes are drilled on the workpiece at the same relative positions as on the template. Plate Jig: A plate jig improves the template jig by incorporating drill bushes on the template. The plate jig is employed to drill holes on large parts, maintaining accurate spacing with each other. Channel Jig: Channel jig is a simple type of jig having a channel-like cross-section. The component is fitted within the channel and is located and clamped by rotating the knurled knob. The tool is guided through the drill bush. Diameter Jig: A diameter jig is used to drill radial holes on a cylindrical or spherical workpiece. Leaf Jig: The leaf jig has a leaf that may be swung open or closed on the work for loading or loading purposes. Ring Jig: Ring jig is employed to drill holes on circular flanged parts. The work is securely clamped on the drill body, and the holes are drilled by guiding the tool through drill bushes. Box Jig: Box jig is of box-like construction within which the work is rigidly held so that it can be drilled or machined from different angles at a single setting depending on which face of the jig is turned toward the tool. Ensure top notch tool & fixture design Our team of experts having knowledge of various manufacturing processes enables them to design & develop high precision tools without any impact on required shape/profile. Visit our website for more details. Types of Fixtures Turning Fixtures: These fixtures are generally mounted on the nose of the machine spindle or a faceplate, and the workpieces hold them. The fixture may have to be provided with a counterweight or balance the unbalance fixture whenever necessary. Milling Fixtures: Milling fixtures are typically mounted on the nose of the machine spindle or a faceplate, and the workpieces hold them. The table is shifted and set in the proper position about the cutter. The workpieces are located in the base of the fixture and clamped before starting the operation. Broaching Fixtures: Broaching fixtures are used on different broaching machines to locate, hold and support the workpieces during the operations, such as keyway broaching operations, such as keyway broaching, hole broaching, etc. Indexing Fixtures: Several components need machining on different surfaces such that their machined surface surfaces or forms are evenly spaced. Such elements must be indexed equally as many as the number of surfaces to be machined. The holding devices (jigs or fixtures) used are made to carry a suitable indexing mechanism. A fixture having such a device is known as an indexing fixture. Grinding Fixtures: These fixtures may be the standard work-holding devices, such as chucks, mandrels, chuck with shaped jaws, magnetic chucks, etc. For external surface grinding, cylindrical grinding utilizes plain or tapered mandrels. The workpiece is located and held on the mandrel with the help of the bore so that the external surface may be machined truly concentric to the bore. For internal grinding, the chuck is the most standard fixture. For holding irregularly shaped components, the fixture is designed the same as turning or boring fixtures. Boring Fixtures: This fixture incorporates almost all the prevailing principles of jig and fixture design; their construction need not be as sturdy as that of the milling fixtures because they never have to bear as heavy cutting loads as involved in milling fixtures because they never have to endure as heavy cutting loads as involved in milling operations. Tapping Fixtures: Tapping fixtures are specially designed to position and firmly secure identical workpieces to cut internal threads in drilled holes. Odd-shaped and unbalanced components will always need such fixtures, especially when the tapping operation is to be carried out repeatedly on a mass scale on such parts. Duplex Fixtures: It is the name given to the fixture which holds two similar components simultaneously and facilitates simultaneously machining of these components at two separate stations. Welding Fixtures: Welding fixtures are carefully designed to hold and support the various components welded in proper locations and prevent distortions in welded structures. For this, the locating element needs to be careful; clamping has to be light but firm, and the placement of clamping elements has to be clear of the welding area. The fixture must be pretty stable and rigid to withstand the welding stresses. Assembly Fixtures: The function of these fixtures is to hold different components together in their proper relative position when assembling them. Source:The Engineers post, https://www.theengineerspost.com/jigs-and-fixturesJigs & Fixtures with differences, Types of Jigs & Fixtures and Constructional details of Jigs & Fixtures, Mechtalk

Read MoreDesigning Jigs and Fixtures

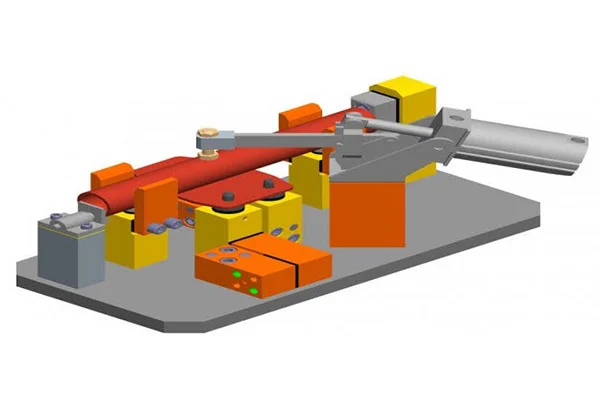

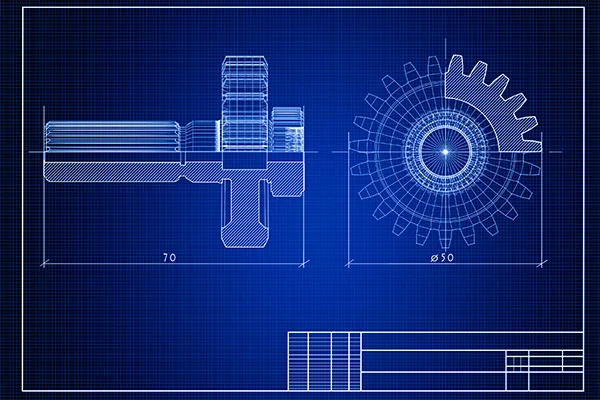

The design of jigs and fixtures is dependent on numerous factors which are analysed to achieve optimum output. Jigs should be made of rigid light materials to facilitate secure handling, as it has to be rotated severally to enable holes to be drilled from different angles. It is recommended that four feet should be provided for jigs that are not bolted on the machine tool, to enable the jig to wobble if not well positioned on the table and thereby alert the operator. Drill jigs provide procedures for proper location of the work-piece concerning the cutting tool, tightly clamp and rigidly support the work-piece during machining, and also guide the tool position and fasten the jig on the machine tool. To achieve their expected objectives, jigs and fixtures consist of many elements: The factors below are to be reflected upon during design, production, and assembly of jigs and fixtures due to the targeted increase in throughput, quality of products, interchangeability, and more accuracy. Elements of Jigs and Fixtures The significant features of Jigs and Fixtures are: The body: The body is the most outstanding element of jigs and fixtures. It is constructed by welding of different slabs and metals. After the fabrication, it is often heat-treated for stress reduction as its main objective is to accommodate and support the job. Clamping devices: The clamping devices must be straightforward and easy to operate, without sacrificing efficiency and effectiveness. Apart from holding the work-piece firmly in place, the clamping devices are capable of withholding the strain of the cutting tool during operations. The need for clamping the work-piece on the jig or fixture is to apply pressure and press it against the locating components, thereby fastening it in the right position for the cutting tools. Locating devices: Thepin is the most popular device applied for the location of work-piece in jigs and fixtures.The pin’s shank is press-fitted or driven into a jig or fixture. The locating width of the pin is made bigger than the shank to stop it from being pressed into the jig or fixture body because of the weight of the cutting tools or work-piece. It is made with hardened steel. Jig bushing or tool guide:Guiding parts like jig bushings and templates are used to locate the cutting tool relative to the component being machined. Jig bushes are applied in drilling and boring, which must be wear resistant, interchangeable, and precise. Bushes are mainly made of a reliable grade of tool steel to ensure hardening at a low temperature and also reduce the risk of fire crackling. Selection of Materials There is a wide range of materials from where jigs and fixtures could be made, to resist tear and wear, the materials are often tempered and hardened. Also, phosphor bronze and other non-ferrous metals, as well as composites, and nylons for wear reduction of the mating parts, and damage prevention to the manufacturing part is used. Some of the materials are discussed below: Other materials for the making of jigs and fixtures include Nylon and Fibre, steel castings, stainless steel, cast iron, high tensile steels, case hardening steels, and spring steels. Reference Charles ChikwenduOkpala, EzeanyimOkechukwu C “The Design and Need for Jigs and Fixtures in Manufacturing” Science Research.Vol. 3, No. 4, 2015, pp. 213-219. DOI: 10.11648/j.sr.20150304.19

Read MoreDesign principles of Jigs and Fixtures

The art of metalworking has a primary concern, locating the part to be machined relative to the platform. A CNC machine starts machining at a specific point corresponding to the fixture and proceeds from there. Therefore, the preciseness with which a job is machined is dependent on the accuracy that holds in the fixture. The accurate location of every part loaded into the fixture is essential. Any deviation in part location adds to the dimensional tolerance that must be assigned to the finished pieces. Furthermore, improper supporting and securing the part in the fixture affects surface finishes by temporarily or permanently deforming it. Hence, techniques for supporting, clamping, and locating must be considered together to assure repeatability from part to part. Basic principles of Jigs and Fixtures design LOCATING POINTS: Locating the work is a prime necessity and requires suitable facilities. The correct setup ensures smooth insertion of a workpiece in the proper position and removing a workpiece from a jig without operational hassles or time consumption. The workpiece position needs to be precise with the guiding tool in the jig or setup pieces in the fixture. FOOLPROOF: A foolproof design of jigs and fixtures does not permit a tool or workpiece to be placed in any other way other than the intended one. REDUCTION OF IDLE TIME: Jigs and Fixtures must be designed in such a way that ensures smooth loading, clamping, machining, and unloading of a WEIGHT OF JIGS AND FIXTURES: A jig and fixture must be compact, easy to handle, and low cost regarding the number of materials used without giving up stiffness and rigidity. JIGS PROVIDED WITH FEET: Some jigs require feet so that they can be placed on the table firmly. MATERIALS FOR JIGS AND FIXTURES: Jigs and Fixtures are usually created with hardened materials to resist wear & tear and avoid frequent damage—for example, Mild steel, Cast iron, Die steel, High-speed steel, Caesium. CLAMPING DEVICE: A suitable clamp is rated for its strength. It should be able to hold a workpiece firmly in its position while bearing the strain of the cutting tool simultaneously, without springing. Broad rules of Jigs & Fixtures Design The 3-2-1 principle Locating a part to be machined involves mainly three steps: Supporting, Positioning, and Clamping. Two main intentions when placing a job on a jig/fixture are: An extensively used method for obtaining these objectives is the 3-2-1 principle or six degrees of freedom for part location. The 3-2-1 method is a work-holding principle where three pins are located on the 1st principle plane, i.e., either XY, YZ, ZX. And two pins are located on the 2nd plane perpendicular to the 1st plane, and at last, one pin on the plane is mutually perpendicular to the 1st and 2nd planes. The aim is to constrain the movement of the workpiece along all three axes. Design objectives of Jigs and Fixtures Before sitting down to design jigs/fixtures, the designer must consider the following points: The designer must know the basics of the process and the tools associated with it for which the jig/fixture is designed. Overall objectives to look out for a while developing such tools are: Reference: National Institute of Technology, Calicut

Read More