The Advantages And Limitations Of Additive Manufacturing: A Comprehensive Overview

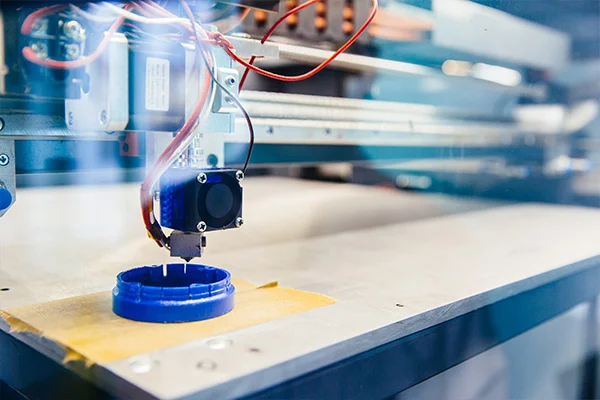

Table of content Top 6 Advantages of Additive Manufacturing: Top 6 Limitations of Additive Manufacturing Conclusion In the last few years, 3D printing and additive manufacturing have enhanced the scope of production. 3D printing is the process of putting layers of material together to make things that are three-dimensional. This technology is better than the old ways of making things in a lot of ways, but it comes with its own set of limitations. Here, we’ll look more closely at the top six pros and cons of additive manufacturing. Top 6 Advantages of Additive Manufacturing: 1.Reduced Time and Cost One benefit of additive manufacturing is that it makes production faster and cheaper. Usually, when making a new product, you start by making a prototype, then the tools, and finally the finished product. This process could take a long time and cost a lot of money. But additive manufacturing makes the process go faster. 2.Complex Geometries With additive printing, you can make things that would be hard to make in any other way. Additive manufacturing can be used to make structures with hollow channels inside and curved surfaces.3 3.Customization and Personalization Additive manufacturing makes it possible to change and personalize products. In traditional manufacturing, the same product is made over and over again, and there is no way to change it. Customers can use additive manufacturing to make one-of-a-kind items with their own specs, sizes, and shapes. 4.Reduced Material Waste If additive manufacturing is used, there may be less need to throw away materials. With traditional ways of making things, like subtractive manufacturing, a lot of materials are wasted. In additive manufacturing, just the right amount of material is used. This cuts down on waste and saves money on materials. 5.Faster Prototyping One more benefit of additive manufacturing is that prototyping can be done more quickly. When standard production methods are used, prototyping can take a long time and cost a lot of money. Additive manufacturing can be used to make prototypes quickly and cheaply. You can easily change designs, try out new materials and shapes, and repeat the process. This makes it easier and cheaper to get products to market faster. 6.Simplified Supply Chains Since additive manufacturing makes it possible to make things only when they are needed, supply chains may be easier to run. Instead of making a lot of the same thing and storing it in warehouses, additive manufacturing lets people make things as they need them. This might make people need less storage space and be less likely to keep things they don’t need. Top 6 Limitations of Additive Manufacturing: 1.Limited Materials One problem with additive manufacturing is that it can only print with a certain number of materials at one time. Even though the number of materials is growing, it is still very small compared to conventional methods. This limitation could affect how well the final product works, how long it lasts, and how well it lasts. 2.Surface Quality A glaring limitation of additive manufacturing is that the surface quality of the parts is still not very good. Especially, when complex structures are made, a smooth surface finish is difficult to achieve. 3.Size Limitations With additive manufacturing, the size of objects may be limited. How big an item is depends on how big the printer is and how much room it has to work with. Larger things may need to be printed in parts before they can be put together. This will take time and make the process harder. 4.Complexity Limitations Using additive manufacturing, you can make buildings with complex shapes, but the shapes can only be complicated. Complex designs can be hard to make because they often need more support structures or post-processing steps, which take more time and money. 5.Limited Scale Another problem with additive manufacturing is that it can only make small quantities. Additive manufacturing is great for making small batches of goods, but it’s not ready yet to make a lot of things at once. This is because additive manufacturing is a slow method that might take a long time to make a lot of parts. 6.Environmental Impact When you use additive printing, it might be hard to get rid of things like support structures and failed prints. Also, if the materials used in additive manufacturing are not recycled or thrown away in the right way, they could hurt the environment. Conclusion In conclusion, additive manufacturing is faster, cheaper, more flexible, and wastes less material. It does, however, have a number of flaws, including a paucity of materials, poor surface quality, small size, and complexity issues. Despite these problems, additive manufacturing is an important part of the manufacturing industry and will continue to change and improve over time. Do you want to go to the next level with additive manufacturing? We can help you at Prescient Technologies. Our software development services could change the way you think about 3D printing and other methods of “additive manufacturing.” References:

Read MoreAdditive Manufacturing: The past and the prominence of 3D Printing

Additive Manufacturing is one of the most significant reforms in a fast-changing world of manufacturing and construction. Additive manufacturing has triggered newer processes, sustainable output, smart machines, and more unique means of operation, management, and increased efficiency. Additive manufacturing is a computer-operated and controlled system that creates three-dimensional objects by carefully sequentially depositing various material compositions in layers. A comprehensive digital layout is fed as design data, and the machine operates accordingly. Additive manufacturing is mainly used for making rapid prototypes and forging complex geometric objects. The other names for Additive Manufacturing are 3D printing, Additive Layer Manufacturing. The technology has gained worldwide prominence with the name of 3D printing. FAQ Commercialization of 3D printers 3D printing is not an archaic process, but rather, it came up in the ’80s. Here is a summary of the history of 3D printers in the last four decades: The 80’s witnessed the first commercial use of additive manufacturing with stereolithography from 3D Systems. The SLA-1 was the first commercially released AM machine. Acrylate resins were commercialized. The Somos stereolithography machine also entered the market in the same year. In the ’90s, Germany’s Electro-Optical Systems sells the first stereolithography system. Fused deposition modeling (FDM), solid ground curing (SGC), and laminated object manufacturing (LOM) were commercialized. Selective laser sintering (SLS) and Soliform stereolithography system were also commercialized. This year saw a bunch of new additives manufacturing systems such as ModelMaker, Solid Center, or EOSINT. An inkjet printing mechanism that deposited wax materials layer by layer was also introduced. The late 2000s saw a rapid growth of the 3D printing machine market. The 3D printing Industry witnessed massive investment 2000’s saw the emergence of new technologies. The world got its first commercially available multi-color 3D printer. The Electron Beam melting machine was one of the groundbreaking 3D printing machines introduced in the early 2000s. In March 2015, Exerial was introduced, a large machine with multiple stations to enable continuous production. Early 3D printers were not very light and convenient to handle. Only after the advent of the 21st century have they become more affordable, straightforward, easy to operate, and versatile enough to be used in a wide range of operations ranging from tools & component manufacture, electronics, metalwork, polymers, etc., product prototypes. Past three years, there has been a tendency to employ 3D printing and AM tech in the real estate industry. Current 3D Printing market trends The worldwide 3D printing products and services market valued at around 12.6 billion U.S. dollars in 2020. The industry is expected to grow at a compound annual growth rate of some 17 percent between 2020 and 2023. As more businesses begin to have their printers, printing software will grow faster than printing services. We can see how fast Additive manufacturing emerged within just three decades and how it is relevant across multiple industrial verticals today. Whether it is about building prototypes, constructing affordable housing, or producing components, AM and 3D printing have offered effective systems that triumph over traditional methods. This technology enables faster product development and market entry, smoother product customization, and seamless integration at lesser cost and time. Thus, additive manufacturing provides OEM manufacturers an excellent opportunity to unleash their products at a higher rate at much lesser expenses for great returns and better customer benefits while ensuring sustainability. Reference: 1. Wohlers, T. and Gornet, T., (2016). History of additive manufacturing, Wohlers Report 2016. 2. Global 3D printing products and services market size from 2020 to 2026, Statista

Read MorePoint Clouds | Point cloud formats and issues

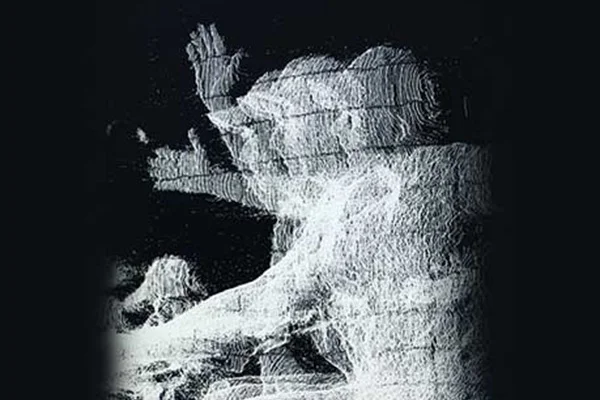

Table of content Different 3D point cloud file formats Challenges with point cloud data Whether working on a renovation project or making information data about an as-built situation, it is understandable that the amount of time and energy spent analyzing the object/project can be pretty debilitating. Technical literature over the years has come up with several methods to make a precise approach. But inarguably, the most prominent method is the application of Point Clouds. 3D scanners gather point measurements from real-world objects or photos for a point cloud that can be translated to a 3D mesh or CAD model. But what is a Point Cloud? A standard definition of point clouds would be – A point cloud collection of data points defined by a given coordinates system. In a 3D coordinates system, for example, a point cloud may determine the shape of some real or created physical system. Point clouds are used to create 3D meshes and other models used in 3D modeling for various fields, including medical imaging, architecture, 3D printing, manufacturing, 3D gaming, and various virtual reality (VR) applications. When taken together, a point is identified by three coordinates that correlate to a precise point in space relative to the end of origin. Different 3D point cloud file formats Scanning a space or an object and bringing it into designated software lets us manipulate the scans further, and stitch them together, which can be exported to be converted into a 3D model. Now there are numerous file formats for 3D modeling. Different scanners yield raw data in different formats. One needs other processing software for such files, and each & every software has its exporting capabilities. Most software systems are designed to receive a large number of file formats and have flexible export options. This section will walk you through some known and commonly used file formats. Securing the data in these common formats enables using different software for processing without approaching a third-party converter. Standard point cloud file formatsOBJ: It is a simple data format that only represents 3D geometry, color, and texture. And this format has been adopted by a wide range of 3D graphics applications. It is commonly ASCII (American Standard Code for Information Interchange). ASCII is a rooted language based on a binary that conveys information using text. Standard ASCII represents each character as a 7-bit binary number. In reverse engineering, characters are the focus of data. E57: E57 is a compact and widely used open, vendor-neutral file format for point clouds, and it can also be used to store images and data produced by laser scanners and other 3D imaging systems. Its compact, binary-based format combines the speed and accessibility of ASCII with the precision and accuracy of binary. E57 files can also represent normals, colors, and scalar field intensity. However, E57 is not universally compatible across all software platforms. PLY: The full form of PLY is the polygon file format. PLY was built to store 3D data. It uses lists of nominally flat polygons to represent objects. The aim is to store a more significant number of physical elements. It makes the file format capable of representing transparency, color, texture, coordinates, and data confidence values. It is found in ASCII and binary versions. PTS, PTX & XYZ: These three formats are familiar and compatible with most BIM software. It conveys data in lines of text. They can be easily converted and manipulated. PCG, RCS & RCP: These three formats were developed by Autodesk to meet their software suite’s demands. RCS and RCP are relatively newer. Binary point cloud file formats are better than ASCII or repurposed file types. It is because the latter is more universal and has better long-term storage capabilities. However, this type of format can be used to create a backup of the original data. If you need to convert binary point cloud files to ASCII, back up your binary files before reformatting them. This way, you can restore your data if something goes wrong. Challenges with point cloud data In reverse engineering, you may encounter several Point Cloud issues. The laser scanning procedure has catapulted product design technology to new heights. 3D data capturing system has come a long way, and we can see where it’s headed. As more and more professionals and end users are using new devices, the scanner market is rising at a quick pace. But along with a positive market change, handling and controlling the data available becomes a vital issue. These problems can result in poor quality point cloud data. Read on to learn more about five key challenges professionals working with point cloud face are: Data Quality: You must identify the quality issues in reverse engineering point cloud data. Reconstruction algorithms differ in their behavior based on the properties of point clouds. Many studies have classified the properties of point clouds by their effect on algorithms. The quality of point clouds affects the precision of the reconstructions. Point clouds produced by body scanners typically contain many duplicated and overlapping patches. These features cause a large amount of noise and redundancy in the final data. Reconstruction of free-form surfaces requires the use of clean-up meshes. This data must be transformed into a model that is consistent and accurate. Fortunately, this task is possible with the help of cloud-to-cloud alignment tools. Data Format: New devices out there in the market yield back data in a new form. Often, one needs to bring together data in different formats from different devices against a compatible software tool. It presents a not-so-easy situation. Identifying the wrong point cloud file format in reverse engineering is of great importance. Often when a company attempts to perform reverse engineering, it will be presented with a point cloud file in the wrong format. It can cause problems because the data is not in the correct format. EMPA has made it their business to work with point clouds as soon as possible. However, this doesn’t mean that you should give up

Read MoreTypes & Benefits of 3D Scanners and 3D Scanning Technologies

Table of content 3D Scanning Technology Types of scanners Benefits of 3D Laser Scanners As we have seen during the introduction, the first step to reverse engineering a product is through scanning with the help of 3D scanners. Early eras have seen the painstaking task of obtaining dimensions of an existing product. These methods were time-consuming and needed attention to detail from the first stage. However, with the rapid development in the scanning technology, the inception of a product has caught speed, and the chances of errors have reduced dramatically, making 3D scanning and measurement a vital part, starting from the design stage to the inspection stage. 3D laser scanning is the technology to capture a physical object’s exact size and shape using a laser beam to create a digital 3-dimensional representation of the same. 3D laser scanners produce “point clouds” of data from the surface of an object. 3D Scanning Technology 3D laser scanning efficiently takes the measurements of contoured surfaces and complex geometries, requiring vast amounts of data for accurate description. Doing this using traditional measurement methods is impractical and time-consuming. Acquiring sizes and dimensions of free-form shapes creates precise point cloud data. The basic working principle of a 3D scanner is to collect an entity’s data. It can either be:an object In reverse engineering, a laser scanner’s primary aim is to provide a lot of information about the design of an object which in the later stages gets converted to 3D CAD models, considering the compatibility of 3D scans and Computer Aided Design (CAD) software. 3D scans are even compatible with 3D printing, requiring specific computer software.3D scanning technologies vary with different physical principles and can be classified as follows:Laser triangulation 3D scanning technology: In this category, the laser scanner projects a laser beam on a surface and measures the deformation of the laser ray. Structured light 3D scanning technology: This technology involves projecting structured patterns of light on an object and acquiring a surface’s shape by measuring the light pattern’s deformation. Photogrammetric technology: It is also known as a 3D scan from photography. It reconstructs an object from 2D to 3D and has specific computational geometrical algorithms for the task. Photogrammetry is cheap, precise, and used to scan large objects such as buildings and stadiums.Photogrammetric technology Laser pulse 3D scanning technology: This unique process collects geometrical information by evaluating the time a laser beam takes to travel between its emission and reception. Computerized Tomography (CT scan): A widely used technique in the medical sector, CT scan is generally used to scan images of the human interiors. CT scans consist of scanning a part and taking a series of 2D images of various sections with X-rays. The 2D images are later superimposed on each other to imitate a 3D model. Contact-based 3D scanning technology: This process requires contact between the probe and the object, where the probe is moved firmly over the surface to acquire data. Types of scanners Apart from scanning technologies, there are various types of 3D scanners. Some are built for short- range scanning, while others are ideal for medium or long-range scanning. The building and usage of specific scanners hugely depend upon the object’s size to be scanned. The scanners for measuring small things vastly differ from those used for large-bodied objects, such as ships. Here is a summary of the types of 3D laser Scanners: Short Range 3D scanners: Short Range 3D scanners utilize either a Laser triangulation technology or Structured Light technology. Laser-based 3D scanners: These scanners employ trigonometric triangulation to capture a 3D object as millions of points. Laser scanners work by projecting a laser beam or multiple laser beams on an object and capturing its reflection with sensors located at a fixed distance from the scanners. Laser scanners come in various designs such as handheld portable units, arm-based, CMM-based, long-range, and single-point long-range trackers. Structured light 3D scanners: These are also known as white light scanners. However, most structured scanners use blue or white LED lights. The light pattern usually consists of a geometrical shape such as a bar, block, or other shape projected onto the object. The sensors consider the edge of the pattern to determine the 3D shape of the object. Blue or white light scanners are generally used to obtain outward dimensions. Medium and Long range scanners: Long-range 3D scanners are used for large objects such as buildings, ships, aircraft, and military vehicles. These scanners rotate and spin a mirror which reflects the laser outward towards the thing or areas to be 3D scanned. Arm-based scanners: Arm-based scanners are handy when measuring small minor parts, as they can be maneuvered by attaching them to the arm and is generally portable. Benefits of 3D Laser Scanners 3D scanners have contributed a lot over the years; needless to say; they come up with many benefits. Some of them are as follows:Able to scan harsh surfaces, such as shiny or dark finishes.This is strictly for handheld or other portable scanners. But given their importance, it is safe to say that the portability of scanners has played a significant role in easing up engineering.The scanning technology has enabled it to capture millions of points in less time.Scanners are less sensitive to changing light conditions and ambient light.Scanning of complex contours and geometrical figures has become more convenient with the invention of groundbreaking scanning technologies.Laser scanners have become so diverse that they are produced depending upon various projects or the objects to be scanned. The right place for your reverse engineering solutions Whether it is scanning or point cloud generation or meshing or 3D model creation, our engineers have been thoroughly trained in end-to-end reverse engineering.

Read More