What is CAD Customization & Automation?

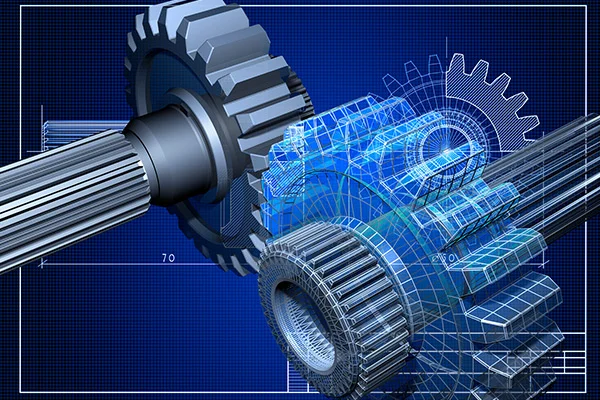

Table of content Steps for Creating a CAD Customization How CAD Customization is done Benefits of CAD Customization CAD Customization and Automation Perks of Automation with CAD Customization There is no doubt that computer-aided design or CAD software has changed the game of manufacturing altogether. The advent of CAD customization has provided immense value to design and production. But what is CAD customization? The manufacturing industry has been using CAD software for some time now. These are when engineering departments, R&D centers & Design departments use Computer-Aided Design (CAD) to ease the product development process, thereby reducing the entire cycle time. CAD software makes our working fast, efficient & accurate. While CAD software offers available tools, it is hard to fathom what each user may find helpful to accomplish particular tasks. Such limitations have pushed the minds of CAD system developers to come up with the capability of customizing their software to cater to their needs. With CAD customization, it is possible to modify or create new tools better suited to our needs. One of the significant improvements we can get with customization is to replace a series of commands with a single tool that accomplishes the task. CAD customization is creating specific enhancements or tools to support CAD software. As the name suggests, CAD customization means customizing or configuring OOTB (out of the box) CAD software to suit the specific needs of a particular organization. CAD customization predominantly involves developing supporting tools for CAD software. It is mainly customized which suits a client’s particular requirements. CAD software built en-masse might not satisfy the needs of every condition, as many organizations have their specific criteria. That is when customizing CAD software comes into play. Customizing existing CAD software is perhaps the fastest and most economical way of getting the work done. Steps for Creating a CAD Customization Before developing customized CAD software, make some preparations as follows: How CAD Customization is done Most CAD systems provide the following two mechanisms: Record-Edit-Play of a macro or VB code VBA stands for Visual Basic Applications, an event-driven programming language by Microsoft. It also allows integration with other applications that use VBA. The implementation of VBA in CAD customization is easy to learn and use. Developers can create application prototypes and receive feedback on designs quickly. VBA provides a highly efficient way for manipulating CAD objects and exchanging data with other applications. Develop an Add-On using Open APIs or toolkits Another method for customizing CAD software is developing add-ons using open-source API and toolkits. One can build API implementations by using a developer toolkit. Nowadays, many API’s come as open-source, which makes the whole operation a lot smoother. APIs can be fabricated as per the requirements and applied as an added feature. One crucial factor is that the API must be compatible with the CAD software. Benefits of CAD Customization Customization of CAD software has indeed introduced us to many benefits, which are as follows: CAD Customization and Automation Design Automation is a knowledge-based process where various engineering concepts are applied in real-time product development. Overlapping CAD customization with automation brings lots of advantages to the table. Since designs are customized per requirements, the outcome is quite precise and enables quick modifications. A good practice is integrating CAD customization with design, process, and systems automation when customizing CAD software. Perks of Automation with CAD Customization: Do you want to have your own customized CAD software? Prescient Technologies has a long list of clients who benefitted a lot from a customized CAD software specifically created for their needs. If you wish to look into our portfolio..

Read MoreWhy CAD Customization is needed

As previously stated; one might encounter complex design situations in engineering scenarios. Earlier, designs were drawn on sheets with pen and necessary scaling instruments and manufactured manually using old school techniques. But now, with the advent of CAD customization, the entire work-process has become easier and smoother than ever. When CAD customization is integrated in CAD software application, a number of advantages occur. With CAD customization, the production of a drawing and design of a mechanical component can be generated with great accuracy. This facilitates the engineers to have tools to make quick modifications to any issues found in the design. The design can be customized according to the needs outlined before or after the CAD design is generated. Need for CAD Customization Implementing a functionality that does not exist in the OOTB package: The activity of CAD customization is carried out when a particular organization needs tailor made CAD software to address their need. It might be a separate functionality that a specific task needs or it might be about a format. Challenges with CAD customization Like every other entity out there, CAD customization comes with its own drawback. One big challenge with CAD customization is keeping it in sync with the latest technology in the market. Also, every CAD software is gets its new releases so it becomes quite hectic to keep a check and customizing accordingly. We have learned before how add-ons/plug-ins has been introduced to add new features to CAD software. Such add-ons are also prone to updates which need to be worked upon to make it compatible with customized software. Modern technology, however, is working its way towards making the process of updating and customizing a more lenient process.

Read MorePoints to consider while developing regression suite for CAD Projects

As the development of software makes its progress, there comes a stage where it needs to be evaluated before concluding it as the final output. This phase is usually known as testing. Testing detects and pinpoints the bugs and errors in the software, which eventually leads to rectification measures. There are instances where the rectifications bring in new errors, thus sending it back to another round of testing, hence creating a repeating loop. This repeated testing of an already tested application to detect errors resulting from changes has a term — Regression Testing. Regression testing is the selective retesting of an application to ensure that modifications carried out has not caused unintended effects in the previously working application. In simple words, to ensure all the old functionalities are still running correctly with new changes. This is a very common step in any software development process by testers. Regression testing is required in the following scenarios: Although, every software application requires regression testing, there are specific points that apply to different applications, based on their functioning and utility. Computer-Aided design or CAD software applications require specific points to keep in mind before undergoing regression testing. Regression testing can be broadly classified into two categories, UI Testing and Functionality Testing. UI testing stands for User Interface which is basically testing an applications graphical interface. Numerous testing tools are available for carrying out UI testing. However, functional testing presents situation for us. This content focuses on the points to take care while carrying out functional regression testing. Here are most effective points to consider for functional regression testing: Failure to address performance issues can hamper the functionality and success of your application, with unwelcome consequences for end users if your application doesn’t perform to expectations.

Read MoreFive points to consider for a CAD Software Development Process

In any software development process, the methodology involved is more or less the same. The most generic requirements are developers, preferred programming language, testers and carefully planned set of actions to perform. The same can be applied to development of CAD software as well. Having CAD software that can actually meet product development needs is an obvious necessity. Although, there is a lot of common ground between a CAD software development project and a regular software development project, there are criteria very specific to CAD software development projects which needs to be addressed. Let us take a walkthrough: Acceptance Criteria Acceptance criteria are a list that mentions user requirements and product scenarios, one by one. Acceptance criteria explain conditions under which the user requirements are desired, thus getting rid of any uncertainty of the client’s expectations and misunderstandings. However, defining acceptance criteria is not simple, but has its complications. Also, it is not convenient to expect a 100% pass rate. In such case, an ideal way is to have a set of test cases with defined input and output data. Algorithmic Complexities To successfully develop a complex product, two critical questions must be answered, how to develop the right product and how to develop the product right.Unlike some of the other problems like interest rate calculations or workflow management system, there is not a defined set of steps that results in the final answer. There are often multiple algorithms for a single issue and the situation becomes more complicated when a particular algorithm, deemed to be perfect for a given situation, may not perform that well in a different scenario, which often leads to trade offs. Tolerances Tolerance is one of the factors to evaluate product quality and cost. It has a significant role. As tight tolerance assignment ensures design requirements in terms of function and quality, it also induces more requirements in manufacturing, inspection and service that results in higher production cost. Most of CAD data works on variables that are doubles and floats and Floating point precision, Tolerance plays a very important role in the algorithms. When using data from other systems say STEP file from other source, if there is a mismatch in the tolerance, the destination system can cause lot of issues. Risk of Regression Adding a new functionality or improving an algorithm always has a risk of impacting the test cases that were working before the fixes. One should always develop a robust test suite for catching regressions while carrying out testing. To create a regression test case suite one must have thorough application knowledge or complete understanding of the product flow. Interoperability The quick emergence of varied CAD software has led designers to democratize, leading to the usage of multiple CAD systems in the design process, thus challenging the CAD interoperability aggressively. Different suppliers require different CAD platforms. It depends on many factors, primarily the nature of the task and product upon which it has to work. Merging different CAD data together without affecting the design intent is quite the hassle. Although, a lot of software these days support different CAD files, there are instances, where the particulars of a project has made the product confined to that one CAD software. Interoperability eases up extra work and whether to make your own software compatible with other, is a decision that should be seriously taken into account.

Read More