The Advantages And Limitations Of Additive Manufacturing: A Comprehensive Overview

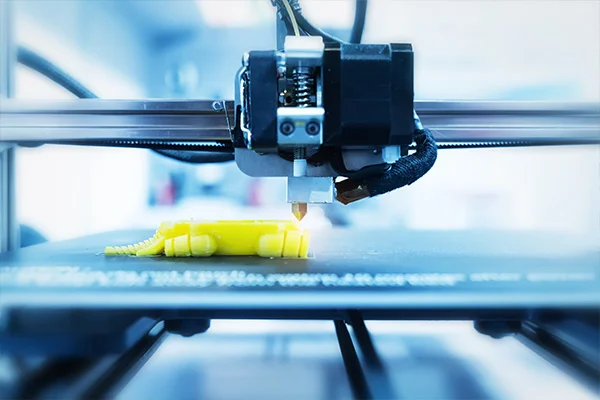

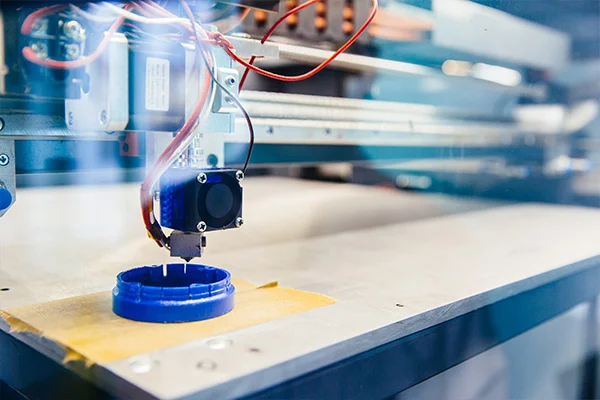

Table of content Top 6 Advantages of Additive Manufacturing: Top 6 Limitations of Additive Manufacturing Conclusion In the last few years, 3D printing and additive manufacturing have enhanced the scope of production. 3D printing is the process of putting layers of material together to make things that are three-dimensional. This technology is better than the old ways of making things in a lot of ways, but it comes with its own set of limitations. Here, we’ll look more closely at the top six pros and cons of additive manufacturing. Top 6 Advantages of Additive Manufacturing: 1.Reduced Time and Cost One benefit of additive manufacturing is that it makes production faster and cheaper. Usually, when making a new product, you start by making a prototype, then the tools, and finally the finished product. This process could take a long time and cost a lot of money. But additive manufacturing makes the process go faster. 2.Complex Geometries With additive printing, you can make things that would be hard to make in any other way. Additive manufacturing can be used to make structures with hollow channels inside and curved surfaces.3 3.Customization and Personalization Additive manufacturing makes it possible to change and personalize products. In traditional manufacturing, the same product is made over and over again, and there is no way to change it. Customers can use additive manufacturing to make one-of-a-kind items with their own specs, sizes, and shapes. 4.Reduced Material Waste If additive manufacturing is used, there may be less need to throw away materials. With traditional ways of making things, like subtractive manufacturing, a lot of materials are wasted. In additive manufacturing, just the right amount of material is used. This cuts down on waste and saves money on materials. 5.Faster Prototyping One more benefit of additive manufacturing is that prototyping can be done more quickly. When standard production methods are used, prototyping can take a long time and cost a lot of money. Additive manufacturing can be used to make prototypes quickly and cheaply. You can easily change designs, try out new materials and shapes, and repeat the process. This makes it easier and cheaper to get products to market faster. 6.Simplified Supply Chains Since additive manufacturing makes it possible to make things only when they are needed, supply chains may be easier to run. Instead of making a lot of the same thing and storing it in warehouses, additive manufacturing lets people make things as they need them. This might make people need less storage space and be less likely to keep things they don’t need. Top 6 Limitations of Additive Manufacturing: 1.Limited Materials One problem with additive manufacturing is that it can only print with a certain number of materials at one time. Even though the number of materials is growing, it is still very small compared to conventional methods. This limitation could affect how well the final product works, how long it lasts, and how well it lasts. 2.Surface Quality A glaring limitation of additive manufacturing is that the surface quality of the parts is still not very good. Especially, when complex structures are made, a smooth surface finish is difficult to achieve. 3.Size Limitations With additive manufacturing, the size of objects may be limited. How big an item is depends on how big the printer is and how much room it has to work with. Larger things may need to be printed in parts before they can be put together. This will take time and make the process harder. 4.Complexity Limitations Using additive manufacturing, you can make buildings with complex shapes, but the shapes can only be complicated. Complex designs can be hard to make because they often need more support structures or post-processing steps, which take more time and money. 5.Limited Scale Another problem with additive manufacturing is that it can only make small quantities. Additive manufacturing is great for making small batches of goods, but it’s not ready yet to make a lot of things at once. This is because additive manufacturing is a slow method that might take a long time to make a lot of parts. 6.Environmental Impact When you use additive printing, it might be hard to get rid of things like support structures and failed prints. Also, if the materials used in additive manufacturing are not recycled or thrown away in the right way, they could hurt the environment. Conclusion In conclusion, additive manufacturing is faster, cheaper, more flexible, and wastes less material. It does, however, have a number of flaws, including a paucity of materials, poor surface quality, small size, and complexity issues. Despite these problems, additive manufacturing is an important part of the manufacturing industry and will continue to change and improve over time. Do you want to go to the next level with additive manufacturing? We can help you at Prescient Technologies. Our software development services could change the way you think about 3D printing and other methods of “additive manufacturing.” References:

Read MoreHow Artificial Intelligence and 3D Printing can collaborate

Artificial Intelligence 3D Printing Machine Learning Applications of AI in 3D printing AI and 3D printing has been a hot tech for sometime and ever since their inception, these two domains has climbed steadfastly on the global market ladder. The 2019-20 global automation market size has displayed this rise. It is obvious that these two domain would cross paths sometime and strike up a beneficial collaboration. The intersection of AI and 3D printing has long been predicted. AI can analyze a 3D model and determine which parts will fail to form the part. 3D printers can also remove material from failed regions and use AI to create a different version. AI can even analyze a part’s geometry and identify a potential problem so an alternative way to create it can be found. The end result? A better-designed part with a high rate of success. Artificial Intelligence The merging of artificial intelligence and 3D printing is an evolution of manufacturing paradigms. Prosthetics design, for instance, is one of the most important applications of 3D printing. As technology advances, artificial intelligence and 3D printers can be used to control 3D printers and increase the number of compatible materials for the process. By combining these two technologies, manufacturers can create new and improved products and production processes. Artificial intelligence and 3D printing will eventually help humans create better prosthetics. The advancement of 3D printing has made it possible to create complex objects without the need for a human. Despite the complexity of the manufacturing process, AI can help to improve the process. The combination of AI and 3D printers will also create new applications. Here are some applications that will benefit from the convergence of these technologies. Once this technology becomes more widespread, it will revolutionize the manufacturing industry. It could even be used to create new prosthetic limbs that can be used for surgery. 3D Printing AI and 3D printing are often associated, but it can also be used to create better products and objects. By automating processes, AI can help eliminate human error and enhance 3D printing performance. The fusion of AI and 3D printing has a number of benefits for manufacturing and quality control. It also helps accelerate the rise of Industry 4.0 and the Industrial Internet of Things. But which use cases will AI have in manufacturing? What are some examples of where AI is already being applied to 3D printing? Machine learning, or AI, is a technology that can analyze a data stream and find hidden relationships. For instance, in the 3D printing process, artificial intelligence helps maintain the material properties of complex alloys, such as titanium, carbon, and other metals. The resulting models can be used for predictive maintenance. Machine learning can even help manufacturers improve spare parts and predict when to replace them. This is an exciting development for manufacturers and researchers alike. Machine Learning Bioprinting, also known as 3D bioprinting, is an emerging field in which machine learning is being used to improve the process of making organoids. This technique involves constructing a scaffold with a specific design to support cell growth and function. The complexity of the scaffold can have a big impact on the printed organ’s function. For this reason, scaffolds should be designed carefully and precisely to optimize the process. Using machine learning in 3-D bioprinting can help detect defects, such as incorrectly positioned cells, curved layers, and microstructure errors. It can also monitor the entire bioprinting process and identify problems before they arise. One such example is shown in Figure 4, which uses CNN to detect defects during the bioprinting process. In this example, images from high-quality cameras during the bioprinting process are input data for the CNN, which analyzes the images to determine whether they are defects. Applications of AI in 3D printing AI has a number of advantages when it comes to 3D printing, including the ability to analyze an object before starting the process, and to predict the quality of the part. The use of machine learning algorithms also improves the fixation process and reduces manufacturing waste. Some projects are even aiming for zero-waste additive manufacturing. AI can also be used to protect important data about the printing process, such as reducing the number of errors. A recent example of an application of machine learning in 3D printing is automated monitoring of 3D printed parts. By integrating image processing and camera data, supervised machine learning algorithms can detect defects during the printing process and help companies fix them without human intervention. The technology can also help companies cut the cost of reprinting parts if they have to fix a problem. Another cost-saving application of artificial intelligence in 3D printing is the guarantee of high- precision prints. A project developed by the University of Southern California has been designed to ensure that parts produced by 3D printing processes meet high-quality standards. The possibilities for AI and 3D printing to collaborate are endless. We’ve seen how they can work together to create a prosthetic hand, and we believe that as these technologies continue to develop, the potential value they can provide each other will only increase.

Read MoreAdditive Manufacturing: The past and the prominence of 3D Printing

Additive Manufacturing is one of the most significant reforms in a fast-changing world of manufacturing and construction. Additive manufacturing has triggered newer processes, sustainable output, smart machines, and more unique means of operation, management, and increased efficiency. Additive manufacturing is a computer-operated and controlled system that creates three-dimensional objects by carefully sequentially depositing various material compositions in layers. A comprehensive digital layout is fed as design data, and the machine operates accordingly. Additive manufacturing is mainly used for making rapid prototypes and forging complex geometric objects. The other names for Additive Manufacturing are 3D printing, Additive Layer Manufacturing. The technology has gained worldwide prominence with the name of 3D printing. FAQ Commercialization of 3D printers 3D printing is not an archaic process, but rather, it came up in the ’80s. Here is a summary of the history of 3D printers in the last four decades: The 80’s witnessed the first commercial use of additive manufacturing with stereolithography from 3D Systems. The SLA-1 was the first commercially released AM machine. Acrylate resins were commercialized. The Somos stereolithography machine also entered the market in the same year. In the ’90s, Germany’s Electro-Optical Systems sells the first stereolithography system. Fused deposition modeling (FDM), solid ground curing (SGC), and laminated object manufacturing (LOM) were commercialized. Selective laser sintering (SLS) and Soliform stereolithography system were also commercialized. This year saw a bunch of new additives manufacturing systems such as ModelMaker, Solid Center, or EOSINT. An inkjet printing mechanism that deposited wax materials layer by layer was also introduced. The late 2000s saw a rapid growth of the 3D printing machine market. The 3D printing Industry witnessed massive investment 2000’s saw the emergence of new technologies. The world got its first commercially available multi-color 3D printer. The Electron Beam melting machine was one of the groundbreaking 3D printing machines introduced in the early 2000s. In March 2015, Exerial was introduced, a large machine with multiple stations to enable continuous production. Early 3D printers were not very light and convenient to handle. Only after the advent of the 21st century have they become more affordable, straightforward, easy to operate, and versatile enough to be used in a wide range of operations ranging from tools & component manufacture, electronics, metalwork, polymers, etc., product prototypes. Past three years, there has been a tendency to employ 3D printing and AM tech in the real estate industry. Current 3D Printing market trends The worldwide 3D printing products and services market valued at around 12.6 billion U.S. dollars in 2020. The industry is expected to grow at a compound annual growth rate of some 17 percent between 2020 and 2023. As more businesses begin to have their printers, printing software will grow faster than printing services. We can see how fast Additive manufacturing emerged within just three decades and how it is relevant across multiple industrial verticals today. Whether it is about building prototypes, constructing affordable housing, or producing components, AM and 3D printing have offered effective systems that triumph over traditional methods. This technology enables faster product development and market entry, smoother product customization, and seamless integration at lesser cost and time. Thus, additive manufacturing provides OEM manufacturers an excellent opportunity to unleash their products at a higher rate at much lesser expenses for great returns and better customer benefits while ensuring sustainability. Reference: 1. Wohlers, T. and Gornet, T., (2016). History of additive manufacturing, Wohlers Report 2016. 2. Global 3D printing products and services market size from 2020 to 2026, Statista

Read More