10 Benefits of Vision-Based Inspection Systems in Manufacturing

- Home

- Blog Details

- October 17 2023

- admin

Table of content

Advantages of Vision-Based Inspection Systems

- Elevated Quality Assurance

- Unsurpassed Accuracy and Consistency

- Energy Modeling and Simulation

- Tangible Cost-Efficiency

- Adaptability and Flexibility

- Insights Driven by Data

- Non-Intrusive Evaluation

- Mitigation of False Positives and Negatives

- Streamlined Documentation and Reporting

- Gaining a Competitive Edge

Conclusion

In the rapidly evolving realm of modern manufacturing, the pursuit of impeccable product quality and streamlined efficiency has become the linchpin of success. Manufacturers are ceaselessly exploring innovative methods to ensure the precision of their products while optimizing intricate production processes.

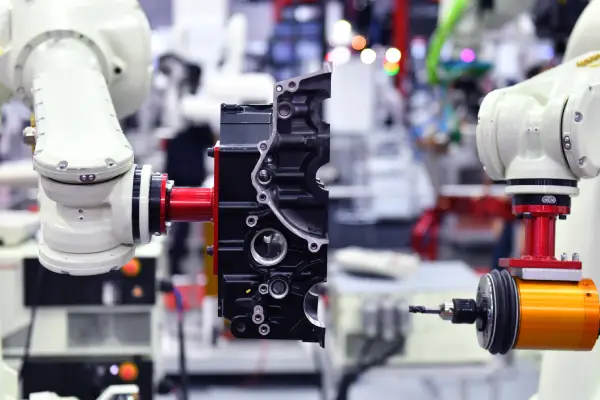

Vision-based inspection systems have emerged as a transformative and indispensable technology in this pursuit. Leveraging advanced imaging techniques coupled with the power of artificial intelligence, these systems conduct meticulous inspections that empower manufacturers to achieve unparalleled levels of quality and productivity.

In this article, we will explore the ten pivotal and multifaceted benefits of integrating vision-based inspection systems into the fabric of the manufacturing landscape.

Advantages of Vision-Based Inspection Systems

Vision-based inspection systems have emerged as a transformative force in manufacturing, combining advanced imaging and artificial intelligence to revolutionize quality control. Their benefits reverberate across the spectrum:

1. Elevated Quality Assurance

Quality is the cornerstone of manufacturing success, and vision-based inspection systems are at the forefront of upholding this standard. Equipped with unparalleled precision, these systems excel in detecting even the most minuscule defects that might elude the human eye.

Through their high-resolution imaging capabilities employed at various production stages, these systems provide a comprehensive canvas for defect identification.

These systems are primed to identify and eliminate faulty products, be it surface irregularities, dimensional deviations, or alignment discrepancies. This ensures that only products meeting stringent quality benchmarks reach the market.

2. Unsurpassed Accuracy and Consistency

Despite their unwavering diligence, human inspectors can succumb to fatigue and the potential for variability. Vision-based inspection systems, in stark contrast, exhibit unwavering precision and consistency.

These systems consistently maintain their remarkable accuracy levels throughout the inspection process, effectively eradicating the potential for errors stemming from human limitations.

The reliability and uniformity in product quality generated by these systems are of paramount importance, particularly in industries such as electronics, pharmaceuticals, and automotive manufacturing.

3. Expedited Inspection Speed

Conventional manual inspection methods often prove to be time-intensive, inevitably leading to production bottlenecks and costly delays. Vision-based inspection systems revolutionize this by expediting the inspection process at remarkable speed.

Propelled by high-resolution cameras and sophisticated algorithms, these systems process colossal volumes of data in real time. This capability ensures the seamless movement of products through the production line without compromising the rigor of the inspection process.

4. Tangible Cost-Efficiency

The seamless integration of vision-based inspection systems translates into substantial cost savings over the long haul. Through the automation of inspections, manufacturers significantly reduce their reliance on labor-intensive manual assessments.

This reduction not only slashes labor costs but also mitigates expenses related to defects, rework, and potential recalls. Furthermore, the heightened operational efficiency and minimized downtime amplify production throughput, thereby enhancing revenue streams and optimizing the overall Return on Investment (ROI).

5. Adaptability and Flexibility

By their very nature, manufacturing processes are susceptible to evolution, often triggered by shifts in product design or specifications. Vision-based inspection systems truly shine in such dynamic scenarios, showcasing their inherent adaptability and flexibility.

With the capacity to swiftly program new inspection criteria, these systems enable seamless transitions between diverse product variants. This adaptability translates to minimized setup times and heightened operational agility, which is crucial in staying ahead in today’s fast-paced manufacturing landscape.

6. Insights Driven by Data

Beyond their role in defect detection, vision-based inspection systems also emerge as robust data repositories. These systems generate abundant data during the inspection, capturing crucial information about defects, patterns, and anomalies. Manufacturers can harness this trove of data to glean valuable insights into their production processes.

This includes pinpointing areas for optimization, refining process parameters, and even preemptively identifying potential issues before they manifest. The data-driven approach empowers manufacturers to make well-informed decisions that elevate both product quality and production efficiency.

7. Non-Intrusive Evaluation

Certain manufacturing processes involve intricate components particularly susceptible to damage through contact-based inspection methods. Vision-based inspection systems offer a non-intrusive solution, relying on visual imaging without requiring physical contact.

This characteristic renders them ideal for scrutinizing delicate or sensitive items, ensuring that products remain pristine and intact throughout the inspection process.

8. Mitigation of False Positives and Negatives

In the intricate domain of inspections, the challenge lies in minimizing the occurrence of false positives (erroneously identifying a defect) and false negatives (failing to detect a defect). Vision-based inspection systems employ advanced algorithms and machine learning to navigate this challenge.

Drawing insights from vast datasets, these systems progressively enhance their ability to differentiate between authentic defects and minor product variations. The result is an elevated level of accuracy, significantly reducing instances of both false positives and negatives.

9. Streamlined Documentation and Reporting

Manufacturers often find themselves in need of meticulous records of their inspection processes for regulatory compliance and rigorous quality control audits. Vision-based inspection systems simplify this task by autonomously generating comprehensive reports and documentation.

These reports encompass not just images but also measurements and other pertinent data collected during the inspection process. This streamlined approach not only expedites compliance efforts but also furnishes an exhaustive record of product quality, an invaluable resource for quality control analysis and ongoing process optimization.

10. Gaining a Competitive Edge

In the current cutthroat manufacturing landscape, maintaining a competitive edge is no longer a choice but an imperative. The adoption of vision-based inspection systems confers a tangible competitive advantage.

Through consistently delivering top-tier products, manufacturers cultivate a reputation for reliability and excellence in the market. This, in turn, translates into heightened customer satisfaction, recurrent business, and enduring brand loyalty, all of which contribute to a formidable market presence.

Conclusion

Vision-based inspection systems represent a revolutionary amalgamation of cutting-edge imaging technology and artificial intelligence within the manufacturing sector. Their impact is wide-ranging, spanning from elevated quality assurance and unparalleled accuracy to expedited inspection speeds and quantifiable cost-efficiency.

Manufacturers embracing this technology embark on a trajectory toward heightened success, simultaneously elevating both product quality and operational efficiency. With the help of Prescient Technologies, commence your journey towards efficiency, accuracy, reliability, and cost-efficiency right away. As technology continues its rapid evolution, the pivotal role of vision-based inspection systems in shaping the contours of the manufacturing landscape is poised to expand even further.