Point Clouds | Point cloud formats and issues

- Home

- Blog Details

- February 19 2019

- admin

Whether working on a renovation project or making information data about an as-built situation, it is understandable that the amount of time and energy spent analyzing the object/project can be pretty debilitating. Technical literature over the years has come up with several methods to make a precise approach. But inarguably, the most prominent method is the application of Point Clouds.

3D scanners gather point measurements from real-world objects or photos for a point cloud that can be translated to a 3D mesh or CAD model.

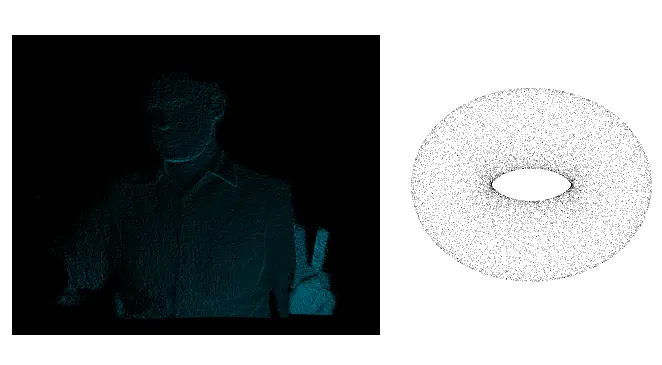

But what is a Point Cloud? A standard definition of point clouds would be – A point cloud collection of data points defined by a given coordinates system. In a 3D coordinates system, for example, a point cloud may determine the shape of some real or created physical system.

Point clouds are used to create 3D meshes and other models used in 3D modeling for various fields, including medical imaging, architecture, 3D printing, manufacturing, 3D gaming, and various virtual reality (VR) applications. When taken together, a point is identified by three coordinates that correlate to a precise point in space relative to the end of origin.

- There are numerous ways of scanning an object or an area with the help of laser scanners which vary based on project requirements. However, to give a generic overview of the point cloud generation process, let us go through the following steps:

- The generation of a point cloud, and thus the visualization of the data points, is an essential step in creating a 3D scan. Hence, 3D laser scanners are the tools for the task. While taking a scan, the laser scanner records a vast number of data points returned from the surfaces in the area being scanned.

- Import the point cloud that the scanner creates into the point cloud modeling software. The software enables visualizing and modeling point cloud, transforming it into a pixelated, digital project version.

- Export the point cloud from the software and import it into the CAD/BIM system, where the data points can convert to 3D objects.

Different 3D point cloud file formats

Scanning a space or an object and bringing it into designated software lets us manipulate the scans further, and stitch them together, which can be exported to be converted into a 3D model. Now there are numerous file formats for 3D modeling. Different scanners yield raw data in different formats. One needs other processing software for such files, and each & every software has its exporting capabilities. Most software systems are designed to receive a large number of file formats and have flexible export options. This section will walk you through some known and commonly used file formats. Securing the data in these common formats enables using different software for processing without approaching a third-party converter.

Standard point cloud file formats

OBJ: It is a simple data format that only represents 3D geometry, color, and texture. And this format has been adopted by a wide range of 3D graphics applications. It is commonly ASCII (American Standard Code for Information Interchange). ASCII is a rooted language based on a binary that conveys information using text. Standard ASCII represents each character as a 7-bit binary number. In reverse engineering, characters are the focus of data.

E57: E57 is a compact and widely used open, vendor-neutral file format for point clouds, and it can also be used to store images and data produced by laser scanners and other 3D imaging systems. Its compact, binary-based format combines the speed and accessibility of ASCII with the precision and accuracy of binary. E57 files can also represent normals, colors, and scalar field intensity. However, E57 is not universally compatible across all software platforms.

PLY: The full form of PLY is the polygon file format. PLY was built to store 3D data. It uses lists of nominally flat polygons to represent objects. The aim is to store a more significant number of physical elements. It makes the file format capable of representing transparency, color, texture, coordinates, and data confidence values. It is found in ASCII and binary versions.

PTS, PTX & XYZ: These three formats are familiar and compatible with most BIM software. It conveys data in lines of text. They can be easily converted and manipulated.

PCG, RCS & RCP: These three formats were developed by Autodesk to meet their software suite’s demands. RCS and RCP are relatively newer.

Binary point cloud file formats are better than ASCII or repurposed file types. It is because the latter is more universal and has better long-term storage capabilities. However, this type of format can be used to create a backup of the original data. If you need to convert binary point cloud files to ASCII, back up your binary files before reformatting them. This way, you can restore your data if something goes wrong.

Challenges with point cloud data

In reverse engineering, you may encounter several Point Cloud issues. The laser scanning procedure has catapulted product design technology to new heights. 3D data capturing system has come a long way, and we can see where it’s headed. As more and more professionals and end users are using new devices, the scanner market is rising at a quick pace. But along with a positive market change, handling and controlling the data available becomes a vital issue. These problems can result in poor quality point cloud data. Read on to learn more about five key challenges professionals working with point cloud face are:

Data Quality: You must identify the quality issues in reverse engineering point cloud data. Reconstruction algorithms differ in their behavior based on the properties of point clouds. Many studies have classified the properties of point clouds by their effect on algorithms. The quality of point clouds affects the precision of the reconstructions. Point clouds produced by body scanners typically contain many duplicated and overlapping patches. These features cause a large amount of noise and redundancy in the final data. Reconstruction of free-form surfaces requires the use of clean-up meshes. This data must be transformed into a model that is consistent and accurate. Fortunately, this task is possible with the help of cloud-to-cloud alignment tools.

Data Format: New devices out there in the market yield back data in a new form. Often, one needs to bring together data in different formats from different devices against a compatible software tool. It presents a not-so-easy situation. Identifying the wrong point cloud file format in reverse engineering is of great importance. Often when a company attempts to perform reverse engineering, it will be presented with a point cloud file in the wrong format. It can cause problems because the data is not in the correct format. EMPA has made it their business to work with point clouds as soon as possible. However, this doesn’t mean that you should give up on capturing your point clouds, as it is not difficult to do.

Data Size: One of the significant challenges in reverse engineering is the massive amount of Point Cloud data. With the advent of new devices, scanning has become cheaper with more significant outputs. It is possible to scan huge assets from a single scan. It has resulted in the creation of tens of thousands of data points. An enormous amount of data points can be challenging to handle and share between project partners. Reverse engineering with large Point Cloud data can be tricky, but it can be done without any major headaches with the proper tools. One method of reverse engineering massive point clouds is by using a system called a “clean-up” or “convolutional” model. The software uses a point cloud containing the data of a body scanner to create a 3D model. This model allows the user to analyze and modify the point cloud data. The software also offers many advanced features, such as multi-resolution support.

Resolution and accuracy: The resolution and accuracy of point cloud data are crucial to reverse engineering. The resolution refers to the smallest object with measurement data, while the accuracy refers to the data closest to the actual part. A study by Berger and Geng found that point clouds contained significant errors. Further, the results showed that the accuracy of the resulting 3D models was poor. The data was also subject to contamination. Ultimately, the quality of the point cloud data will affect the accuracy of a reverse engineering model.

Inter-operability: Integration of new technologies with existing software can be arduous. Although, with the careful investment of time and money, the goal can be achieved nonetheless.

Access: All the professionals involved in the entire lifecycle of a product can benefit from having access to point cloud data. But multiple datasets in multiple formats usually make it more of a hassle.

Ownership: Who owns point cloud data? In the past, EPCs and the contractors who capture the data become custodians of the information.

Reverse engineering involves acquiring knowledge about a lost design. It has evolved from manual measurements to harnessing the power of 3D scanning technologies. The objective of this paper is to survey the literature on reverse engineering, production control, and surface ASCIImodeling.

The right place for your reverse engineering solutions

Whether it is scanning or point cloud generation or meshing or 3D model creation, our engineers have been thoroughly trained in end-to-end reverse engineering.