What is Mesh and what are the types of Meshing

- Home

- Blog Details

- February 19 2019

- admin

For those acquainted with mechanical design and reverse engineering, they can testify to the fact that the road to a new product design involves several steps. In reverse engineering, the summary of the entire process involves scanning, point cloud generation, meshing, computer-aided designing, prototyping and final production. This section covers a very crucial part of the process — Meshing or simply put, Mesh.

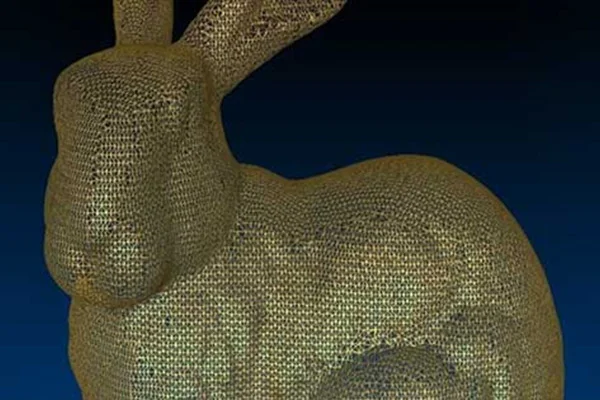

To put a simple definition, a mesh is a network that constitutes of cells and points.

Mesh generation is the practice of converting the given set of points into a consistent polygonal model that generates vertices, edges and faces that only meet at shared edges. It can have almost any shape in any size. Each cell of the mesh represents an individual solution, which when combined, results in a solution for the entire mesh.

Mesh is formed of facets which are connected to each other topologically. The topology is created using following entities:

- Facet – A triangle connecting three data points

- Edge – A line connecting two data points

- Vertex – A data point

These include:

- Face-vertex meshes

- Winged edge meshes

- Corner tables

- Vertex-vertex meshes

Types of Meshing

Meshes are commonly classified into two divisions, Surface mesh and Solid mesh. Let us go through each section one by one.

Surface Mesh

A surface mesh is a representation of each individual surface constituting a volume mesh. It consists of faces (triangles) and vertices. Depending on the pre-processing software package, feature curves may be included as well.

Generally, a surface mesh should not have free edges and the edges should not be shared by two triangles.

The surface should ideally contain the following qualities of triangle faces:

- Equilateral sized triangles

- No sharp angles/surface folds etc. within the triangle proximity sphere

- Gradual variation in triangle size from one to the next

The surface mesh generation process should be considered carefully. It has a direct influence on the quality of the resulting volume mesh and the effort it takes to get to this step.

Solid Mesh

Solid mesh, also known as volume mesh, is a polygonal representation of the interior volume of an object. There are three different types of meshing models that can be used to generate a volume mesh from a well prepared surface mesh.

The three types of meshing models are as follows:

- Tetrahedral – tetrahedral cell shape based core mesh

- Polyhedral – polyhedral cell shape based core mesh

- Trimmed – trimmed hexahedral cell shape based core mesh

Once the volume mesh has been built, it can be checked for errors and exported to other packages if desired.

Types of Meshing as per Grid Structure

A grid is a cuboid that covers entire mesh under consideration. Grid mainly helps in fast neighbor manipulation for a seed point.

Meshes can be classified into two divisions from the grid perspective, namely Structured and Unstructured mesh. Let us have a look at each of these types.

Structured Mesh

Structured meshes are meshes which exhibits a well-known pattern in which the cells are arranged. As the cells are in a particular order, the topology of such mesh is regular. Such meshes enable easy identification of neighboring cells and points, because of their formation and structure. Structured meshes are applied over rectangular, elliptical, spherical coordinate systems, thus forming a regular grid. Structured meshes are often used in CFD.

Unstructured Mesh

Unstructured meshes, as the name suggests, are more general and can randomly form any geometry shape. Unlike structured meshes, the connectivity pattern is not fixed hence unstructured meshes do not follow a uniform pattern. However, unstructured meshes are more flexible. Unstructured meshes are generally used in complex mechanical engineering projects.

Get access to our mesh tools library today

Mesh Tools library offers a comprehensive set of operation for meshes for all your needs. Developed in C++, this library can be easily integrated in to your product. To learn more,