Issues Faced in Industry 4.0

- Home

- Blog Details

- September 17 2021

- admin

The 21st century is the era of digital transformation where companies are trying to blend operations with automation information and data exchange. The amalgamation of cyber-physical systems, the Internet of Things (IoT), Artificial Intelligence, and cloud computing gave rise to a new generation known as Industry 4.0 or the 4th industrial revolution.

The rise of Industry 4.0 and digital hegemony has changed the face of the manufacturing, industrial, transport, and service sector. All these divisions are giving rise to a new kind of workplace which is popularly called Smart Factories. Smart Factories are just digitalized, automated workspaces capable of accomplishing their assigned objectives with limited human intervention.

A PWC survey suggests that 91% of industrial companies have invested in creating smart factories. Keeping the agendas and ROI on a clear viewpoint, companies now understand the long-term implications of such investment, and they are willing to be in the race putting time and work as much as possible.

However, there are so many cases of businesses that stagger through the process despite setting the ball in motion, only to fail in a successful large-scale rollout. Why do such companies fail to effectively transform their digital, automated ambitions into a full-scale fruitful output?

There are specific backlogs that hamper the smooth journey of a successful digitalized business. Very few have been able to use industry 4.0 to its true potential. Every journey is rife with hurdles; this is a part of every story. There are challenges to face, but there are ways to address & overcome these challenges. If the right step is not taken, the challenges will act like a monkey wrench thrown into a full throttle locomotive engine. Competition is good, and everyone should strive to stay ahead in the race these days. Let us check out some challenges that cause issues to a company’s successful implementation of industry 4.0. We will also look into the tips that can help overcome these challenges.

Cyber threat and security: Cyber connectivity is one of the most prominent pillars of building an industry 4.0 standard workspace. Digitalization and interconnectivity are the prime features while connecting the entire system via the Internet of Things. It opens up the possibility of cyber-attacks and presents a cybersecurity challenge. A cyber attack can cripple your organization and your reputation as a trustworthy company. Cyber-attacks can be a nemesis unless you have a robust cyber security infrastructure in place, whether it is malware, ransomware, or a DDoS attack.

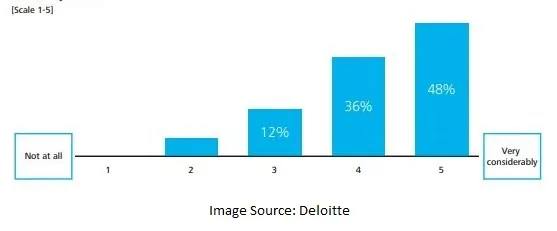

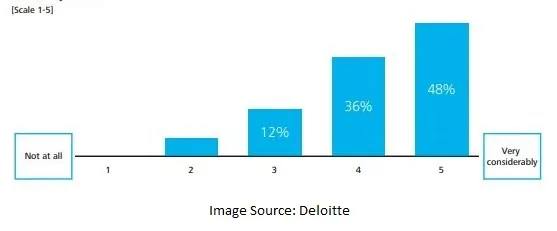

The threat of cyber-attack is such that a Deloitte survey suggests 48% of respondents believe cyber- attacks will increase due to growing industry 4.0.

To address this issue, ensure the following steps:

Create an up-to-date inventory of digital assets and chalk up a schematic workflow of how the entire network works. It is will you in understanding existing loopholes.

Build an authentication system to safeguard physical, digital, and workforce assets.

Your organization must have a sound monitoring system to detect any anomaly and raise an alert. You should also have a dedicated team of experts to carry out rectification & maintenance tasks if needed.

Build an effective risk management contingency plan in case the situation goes south. In such a way, you will have processes, instructions ready to recover lost data and IT assets.

Usable data & its interpretation: Industry 4.0 has enabled data collection. The 21 st century is all about how to manipulate and leverage accumulated data. However, a lot of many businesses struggle to interpret such data. Understanding data can go a long way, like improving key performance indicators, understanding market & consumer trends, analyzing workforce, ROI forecast, etc. The correct evaluation data allows for the proper implementation of the right tech tools. Usually, business owners and manufacturers don’t know what to do with such a large amount of data and sit back wondering how to interpret them.

Since data interpretation and implications are massive, business owners must use the right technologies to carry out such operations. AI is of great importance in this regard. Data collection can be automated, and machines can leverage data and give back valuable insights. Machines can perform calculations, predict probable scenarios on recorded history, simulate different situations to analyze the best possible outcome, and give clear output.

Return on Investment (RoI): Every business ultimately strives for profit. RoI is a complicated subject that is intimidating for business owners and discourages them from stepping up further. Companies wish to look towards the future; they want to know what’s in store for them after an investment, whether it is worthy or not, and understandable.

To address that, companies need to look further than just what the numbers predict. They must understand technology in terms of numbers and predictions and productivity, efficiency, & cost-cutting. There should be a system for detecting flaws and human factor errors. The focus should not only be on the proof of concept but also proof of value. It is essential to know that consumers see the value and not the journey a product or service goes through to reach them. There must be a dedicated CRM, Salesforce, Cloud service to understand the consumer point of view.

A Deloitte survey has revealed that 25% of manufacturing companies have incorporated customer insights in their development and production processes.

Up-to-date workforce technical skills: One must beg for a question, is the workforce well versed with digitalization? Businesses often face a problem with their crew that somehow fails to compliment the advantages industry 4.0 technology offers. Either they are not aware, or they do not want to familiarise themselves with ever-evolving tech. Understandably, there is a shortage of highly skilled employees who understand the ins and outs of these technologies. Still, companies can spare some capital to educate their employees to speed up the familiarization process. Businesses must look for employees who possess digital dexterity to understand digital systems and tools involved. A properly trained workforce can ensure the smooth functioning of operations, thereby productivity. Let’s not forget the rise of chatbots in the customer service sector. Customer grievances are essential feedbacks, and pre-programmed chatbots can make customer service more accessible.

Interoperability and Integration: A significant concern of already existing businesses is interoperability. It delays a company’s run at innovation. There needs to be a clear-cut demarcation line between components, tools, products, systems, and vendor partners.

Another matter of concern is integration. Some businesses thrived on old, outdated legacy data systems such as ERPs to Microsoft Excel sheets. Incorporating new technology becomes a headache since a company’s concern revolves around spending a fortune to set up and integrate the same with not-so- flexible systems. They do not want to sit around spending a big chunk of time coordinating plans and connecting the dots.

However, today’s fast-evolving tech landscape makes it far more manageable than companies realize. Flexible and friendly IoTs and AIs provide seamless integration. All businesses need to add an extra blanket to the existing system and easily blend in without significant modifications and adjustments. Companies can start by classifying possible systems and data that need to be adjusted to accommodate integration + automate manual processes such as updating ledgers, lists, and reports. AI can be trained to carry out such specific jobs.

We understand the Covid-19 pandemic has staggered so many businesses around the world. Companies and manufacturers need to find unconventional solutions to get back on track as the world slowly walks towards normalcy. The tech world is ever-changing, and if we go by history, the ones that can adapt and change with time can go a long way. The blog might not talk about every issue in the industry 4.0 journey since they vary with an individual entity. As the tech world evolves, the hurdles develop as well. This blog can be a lighthouse for starters who embark on their industry 4.0 journey.

References:

https://www2.deloitte.com/content/dam/Deloitte/ch/Documents/manufacturing/ch-en-manufacturing-industry-4-0-24102014.pdf