Remote Machine Monitoring

Reduce on-site visit costs, simplify warranty management, and deliver unmatched value to your customers with our cutting-edge solution.

10% - 20%

100%

5% - 10%

10% - 20%

100%

5% - 10%

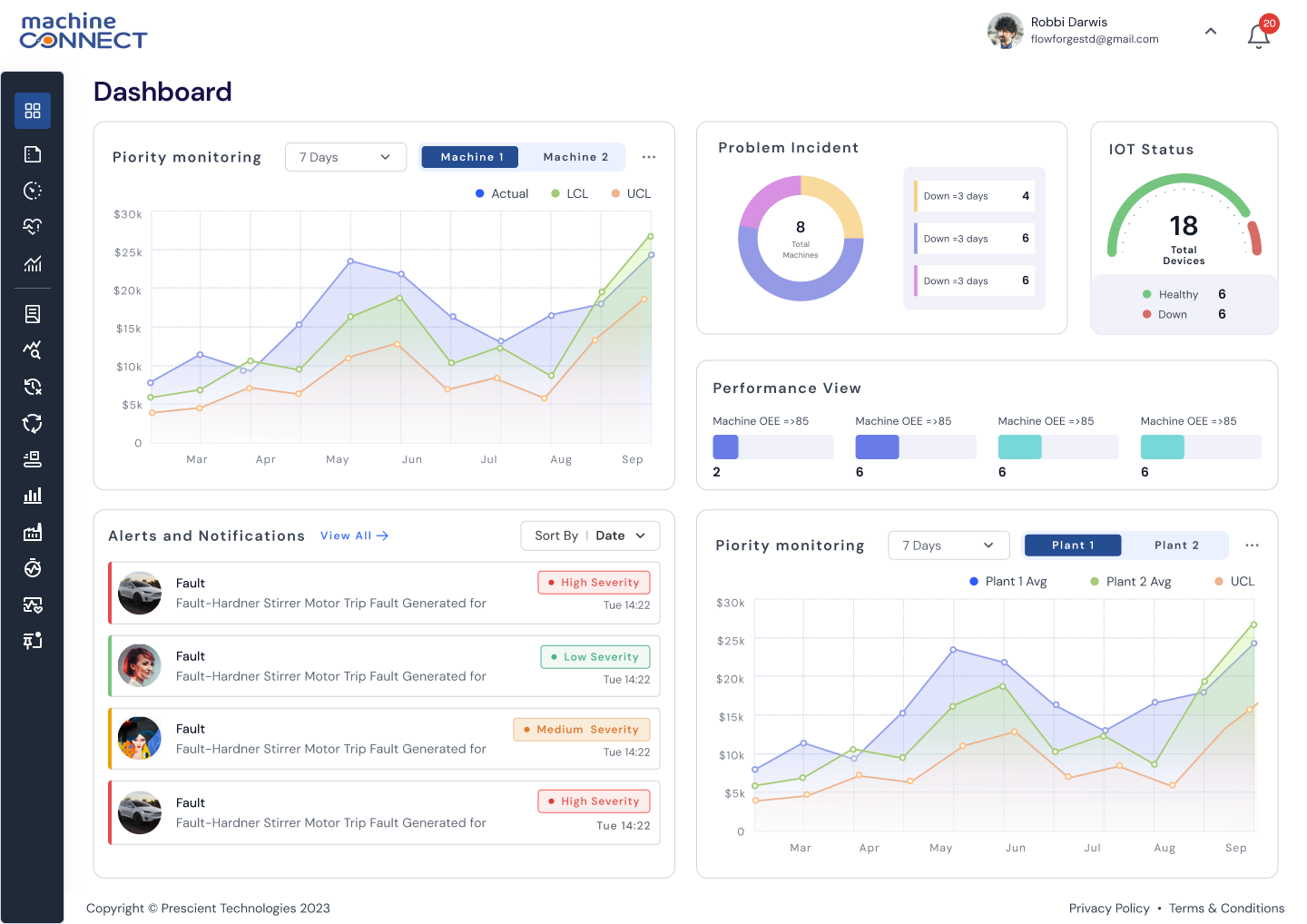

Real-Time Monitoring

With machineCONNECT’s real-time monitoring, you gain instant visibility into your machines’ operational health. By continuously tracking machine data, you can make faster decisions, prevent potential failures, and maintain uninterrupted production.

Machine

Status

Customer

Dashboards

Warranty

Management

Performance Tracking

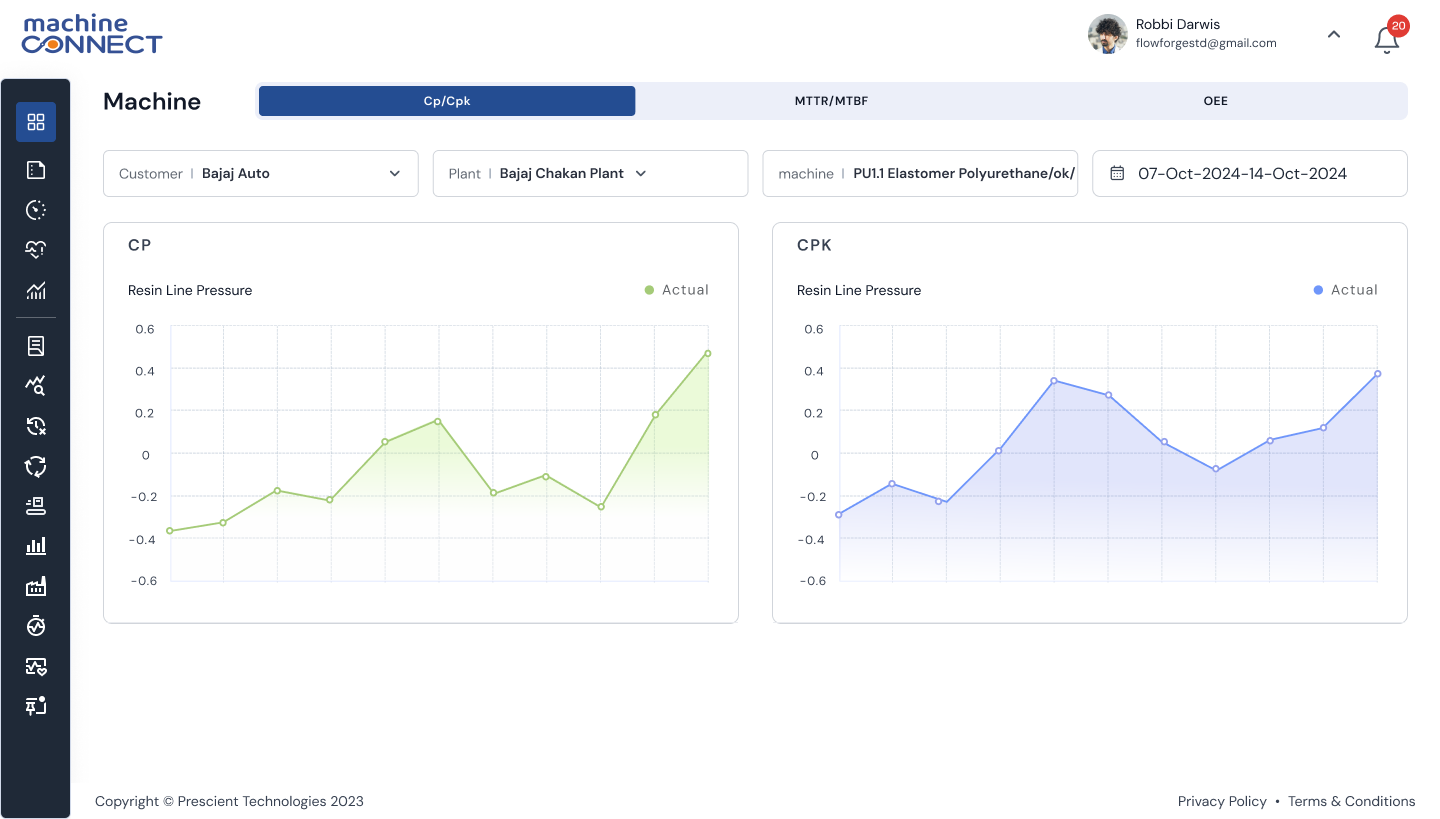

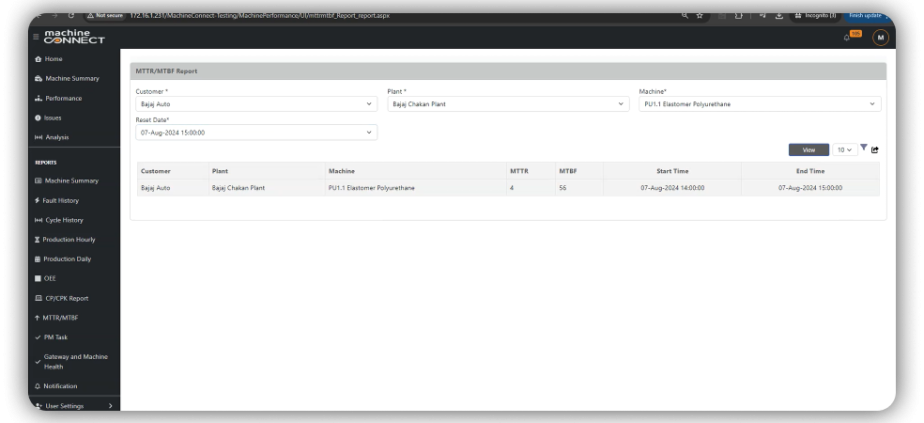

With machineCONNECT you can Track crucial metrics like Overall Equipment Effectiveness (OEE), Mean Time Between Failures (MTBF), and Mean Time to Repair (MTTR) with ease. This performance data helps you understand machine productivity and optimize both machine usage and repair schedules.

CP/CPK

OEE

MTTR – MTBF

Performance Tracking

With machine CONNECT you can Track crucial metrics like Overall Equipment Effectiveness (OEE), Mean Time Between Failures (MTBF), and Mean Time to Repair (MTTR) with ease. This performance data helps you understand machine productivity and optimize both machine usage and repair schedules.

CP/CPK

OEE

MTTR – MTBF

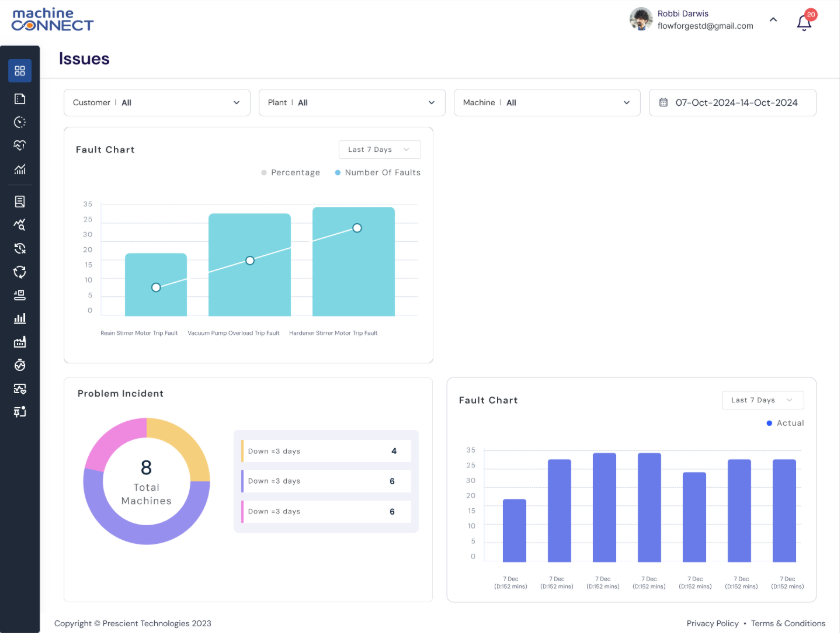

Remote Diagnostics

Remote diagnostics enable you to solve machine issues without the need for on-site visits, saving time and reducing costs. By remotely accessing machine data, you can identify problems early and provide quick resolutions, enhancing customer satisfaction and reducing downtime.

Alerts &

Notifications

Fault

Tracking

Costs

Saving

Inputs for R&D

Data from machines in the field is invaluable for improving your product design and performance. With machineCONNECT, real-time data feedback helps your R&D team innovate and make informed decisions that enhance machine efficiency and reliability.

Enhanced Product Design

Data-Driven

Innovation

Faster

Iteration

Inputs for R&D

Data from machines in the field is invaluable for improving your product design and performance. With machineCONNECT, real-time data feedback helps your R&D team innovate and make informed decisions that enhance machine efficiency and reliability.

Enhanced Product Design

Data-Driven

Innovation

Faster

Iteration

Predictive Maintenance

With machineCONNECT’s predictive maintenance, you can proactively maintain your machines, reducing the risk of unexpected failures. Our solution uses real-time data analytics and machine learning algorithms to predict when your machines are likely to experience issues. This allows you to schedule maintenance at the optimal time-before problems occur, ensuring minimal downtime and maximizing operational efficiency.

Reduced

Downtime

Optimized Maintenance

Schedules

Cost

Savings

Guide to Remote

Machine Monitoring

System

A complete guide to understanding, selecting, and

implementing real-time machine monitoring and optimization

Why Choose machineCONNECT?

Ready to Transform the Way You Sell Machines?

Ready to Transform the Way You Sell Machines?

Our transition to smart machines has been effortless, enabling us to monitor critical parameters remotely and deliver unparalleled value to our customers through proactive, data-driven insights.

Our transition to smart machines has been effortless, enabling us to monitor critical parameters remotely and deliver unparalleled value to our customers through proactive, data-driven insights.

Frequently Asked Questions

Real-time machine monitoring involves tracking the performance and status of machines as they operate. It uses sensors and data collection to provide instant insights into machine health, production metrics, and performance trends. This allows manufacturers to detect issues early, optimize productivity, and ensure smooth operations without unexpected interruptions.

Predictive maintenance uses data from sensors and historical performance to predict when a machine is likely to fail or need maintenance. By identifying issues before they escalate, it allows maintenance teams to address potential problems during planned downtimes, significantly reducing the chances of unexpected breakdowns and improving overall machine availability.

machineCONNECT is an after-sales intelligent monitoring system that enables manufacturers to monitor their machines in real time, detect faults, track performance, and facilitate predictive maintenance.

Yes, MachineConnect is designed to integrate seamlessly with a variety of existing systems, including MES, ERP, and SCADA systems. Its flexible API and modular structure ensure that it can be customized to work with your current infrastructure, enabling smoother data flow and unified machine management.

Remote diagnostics allow technicians to monitor, assess, and troubleshoot machine issues from a distance. Through MachineConnect, real-time data from machines is transmitted to a central dashboard, enabling experts to identify and fix issues without being physically present. This minimizes downtime and speeds up response times for resolving problems.

The pricing for MachineConnect depends on the scale of your operations and the specific features you require. We offer flexible pricing plans based on the number of machines, integrations, and any additional services needed. For a detailed quote tailored to your business, please contact our sales team or request a consultation.

machineCONNECT prioritizes data security and utilizes industry-standard encryption and security protocols to ensure that the monitored data is protected and only accessible to authorized personnel.

machineCONNECT users have access to comprehensive technical support and training to ensure they can maximize the benefits of the system and address any issues that may arise.

Latest Blogs

Learn more about machineCONNECT

© 2024 Prescient Technologies | All Rights Reserved | Powered by WebwideIT

Legal Privacy Policy