Part Segregation

Ensuring Product Quality Through Effective Separation

Transform Your Inventory Management with Advanced Part Segregation

In today’s fast-paced manufacturing and inventory management landscapes, efficient organization is paramount. Here at Prescient Technologies, we understand the challenges of maintaining accurate part segregation. We offer a comprehensive suite of services, powered by cutting-edge technologies, to transform your inventory management.

Our Powerful Part Segregation Solution

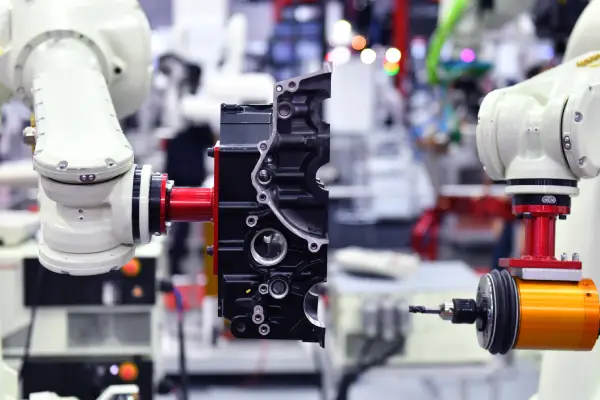

Automated Scanners

Leverage high-speed, non-contact scanners with machine vision and AI capabilities for rapid and accurate part identification and segregation based on pre-defined criteria (barcodes, QR codes, or part features).

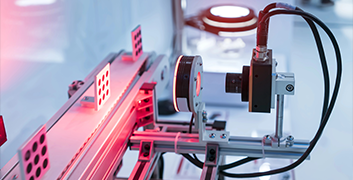

Optical Laser Systems

Employ the precision of laser technology to ensure parts meet dimensional specifications. This aids in segregation based on size and shape for perfect compatibility within your assemblies.

Thermal Imaging Cameras

Go beyond the surface with thermal imaging. Identify potential internal defects or temperature variations that might necessitate separate storage or handling procedures.

Download our free guide now and revolutionize your inventory management!

Methods of Part Segregation

Physical Barriers

Using bins, containers, designated storage areas, or even designated sections on shelves to keep parts separated.

Labeling and Coding

Implementing clear labeling systems with part identification, quality grades, or other relevant information to ensure proper segregation and tracking.

Inventory Management Software

Utilizing software systems to track part location, quantity, and segregation criteria within the overall inventory.

Benefits of Part Segregation

Improved Quality Control

Easier identification and handling of defective parts minimizes the risk of them being used in finished products.

Enhanced Efficiency

Organized storage and retrieval of parts streamline production processes and reduce wasted time searching for components.

Reduced

Errors

Clear segregation minimizes the risk of picking or using the wrong parts during assembly.

Inventory Accuracy

Segregated storage allows for better stock control and identification of potential inventory issues.

Safety and Regulatory Compliance

Ensures proper handling and storage of potentially hazardous or regulated parts.

Why Choose Prescient Technologies for Part Segregation?

Enhanced Accuracy

Eliminate human error with our automated systems, ensuring parts are consistently categorized and stored correctly.

Improved Efficiency

Streamline workflows with faster and more reliable part identification and retrieval.

Optimized Space Utilization

Utilize our advanced segregation methods to maximize storage capacity and minimize wasted space.

Real-Time Visibility

Gain complete transparency into your inventory with real-time data on part location and segregation status.

Reduced Costs

Minimize errors, optimize processes, and save time to reduce overall operational costs.

Part Segregation in Different Industries

Manufacturing

Finds surface defects, assembly errors, and misaligned parts.

Electronics

Inspects circuit boards, solder joints, and semiconductor wafers.

Automotive

Detects paint flaws, scratches, and structural issues.

Pharmaceuticals

Checks packaging, labels, and tablet quality.