End-of-Line Inspection

Advanced systems for perfect product quality

End-of-Line Inspection: The Ultimate Quality Assurance Solution

End-of-Line (EOL) inspection, also known as functional testing, occurs at the very end of the production line. It’s your final opportunity to identify and rectify any defects or malfunctions before products are shipped to customers.

In today’s competitive manufacturing landscape, delivering defect-free products is paramount. End-of-line (EOL) inspection is your final quality checkpoint, safeguarding your brand reputation and customer satisfaction. Prescient Technologies empowers manufacturers with cutting-edge automated EOL testing solutions to eliminate defects and optimize production processes.

Our End-of-Line Inspection Solution

Automated Scanners

High-speed, non-contact machines with eagle-eyed vision detect even the smallest surface flaws

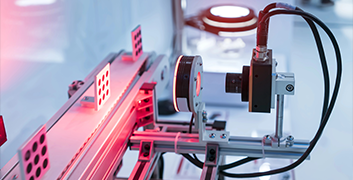

Optical Laser Systems

Laser precision ensures your products meet exact size requirements, guaranteeing a perfect fit.

Thermal Imaging Cameras

See beyond the surface with thermal imaging, revealing hidden defects traditional methods might miss.

Benefits of EOL Inspection

Smoother Production

Early defect detection keeps your production line running smoothly.

Reduced Costs

Prevent defective products and rework to save money in the long run.

Data-Driven Insights

Gain valuable data on defects and improve your processes continuously.

Contact us today for a free consultation!

Ensuring Quality

Key Aspects and Methods of End-of-Line Inspection in Manufacturing

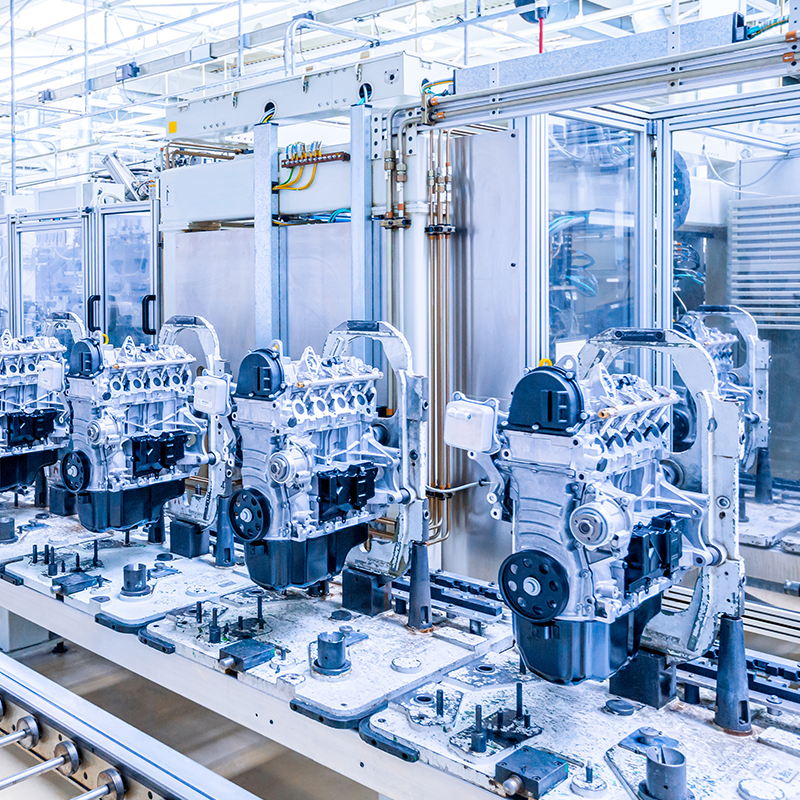

End-of-line inspection is vital in manufacturing to ensure products meet quality standards before reaching customers. This process uses various techniques based on the product type, including quality control to meet requirements, defect detection, compliance with industry standards, functionality testing, aesthetic checks for visual flaws, and dimensional verification to ensure correct sizes.

Improved Product Quality

Ensures only products that meet quality standards reach the customer.

Reduced Waste

Early detection of defects can prevent defective products from reaching the end of the line.

Cost Savings

Reducing the cost of recalls and rework.

Customer Satisfaction

Delivering high-quality products enhances brand reputation and customer satisfaction.

Inspection Methods

Ensure product quality with end-of-line inspection methods, including environmental, dimensional, non-destructive, electrical, visual, and functional testing. These techniques guarantee durability, accuracy, and compliance in manufacturing

Functional Testing

Ensures products perform as intended, encompassing software checks for electronics, pressure assessments in piping, and durability tests for mechanical components.

Visual Inspection

Human inspectors manually check for defects, while automated systems use cameras and computer vision for detection.

Dimensional Inspection

Uses Coordinate Measuring Machines (CMMs) for precise measurement of physical geometries, and Laser Scanning to create detailed 3D models for comparison with design specifications.

Technologies Used

Machine Vision Systems

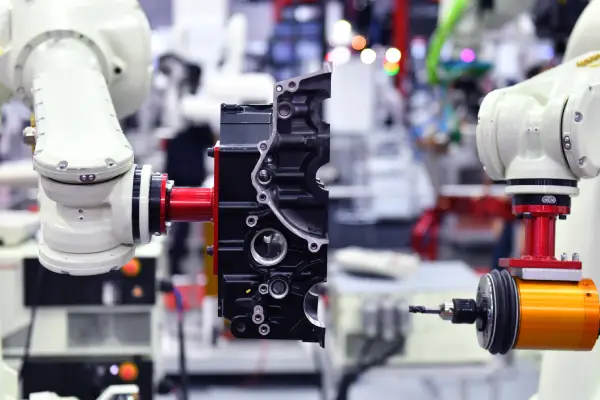

Robotics

IoT Sensors

Artificial Intelligence

Data Analytics

Why Traditional EOL Inspection Doesn't Deliver

Human Error

Even the most experienced inspectors can miss subtle flaws due to fatigue, inattention, or inconsistencies in visual assessment.

Limited Scope

Traditional methods often rely on visual inspection alone, failing to detect hidden defects or internal issues.

Slow and Laborious

Manual inspection is time-consuming, impacting production speed and potentially leading to bottlenecks.

Subjectivity

Quality assessments can be subjective, leading to inconsistencies in defect identification and potential rework needs.

Limited Data Insights

Traditional methods offer minimal data on defect types and trends, hindering proactive process improvement.

End-of-Line Inspection in Different Industries

Manufacturing

Finds surface defects, assembly errors, and misaligned parts.

Electronics

Inspects circuit boards, solder joints, and semiconductor wafers.

Automotive

Detects paint flaws, scratches, and structural issues.

Pharmaceuticals

Checks packaging, labels, and tablet quality.