Dimensional Inspection

Comprehensive Dimensional Inspection for Quality Assurance

Dimensional Inspection: Ensuring Precision in Every Part

Dimensional inspection is essential for upholding the quality of your manufacturing process. It guarantees that every component, from initial prototypes to final products, adheres to the specifications outlined in engineering drawings. This detailed process involves measuring critical aspects of an object—such as length, width, height, angles, and other geometric features—to ensure accuracy and consistency throughout production.

What Do We Measure During Dimensional Inspection?

- Length, Width, and Height

- Angles and Perpendicularity

- Roundness, Flatness, and Other Geometric Characteristics

- Position and Shape Profiles

- Surface Characteristics and Edge Sharpness

- Thickness and Uniformity

Prescient’s Dimensional Inspection Services

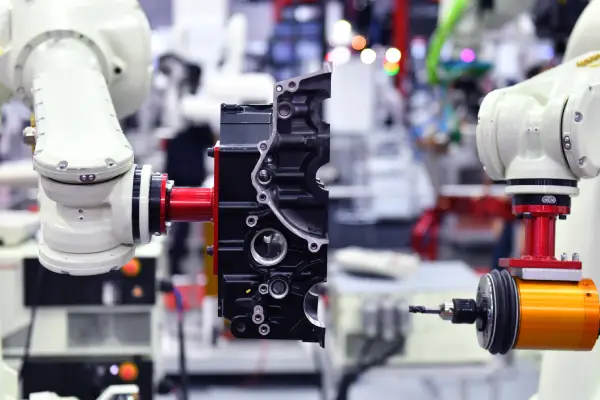

Automated Scanning

We employ advanced 3D scanning systems to capture highly detailed point clouds of your parts. This non-contact method allows for fast and efficient measurement of complex geometries.

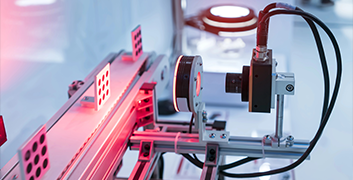

Optical Laser Scanning

Our high-precision laser scanners provide unmatched accuracy for critical features and tight tolerances. This technology enables intricate surface profile measurements for optimal quality control.

Thermal Imaging Cameras

We utilize thermal cameras to identify potential defects or inconsistencies in material properties. This non-destructive technique can reveal hidden issues that traditional methods might miss.

Benefits of

Dimension

Inspection

Unmatched Accuracy

Our advanced measurement technologies guarantee precise results, ensuring your parts conform to specifications.

Enhanced Efficiency

Automated scanning and non-contact methods expedite the inspection process, minimizing downtime and maximizing production throughput.

Expert Support

Our team of experienced professionals is here to help you select the most suitable inspection method for your specific needs.

Comprehensive Analysis

We provide detailed inspection reports that go beyond simple measurements and offer valuable insights into your production processes.

Why is Dimensional Inspection Important?

Ensures Quality and Avoids Errors

Accurate dimensional data allows engineers to identify and fix inconsistencies during production, preventing defective parts and costly rework.

Maintains Tolerance Levels

Manufacturing tolerances define the acceptable range for each dimension. Dimensional inspection ensures parts stay within these tolerances, guaranteeing proper assembly and functionality.

Meets Regulatory Requirements

Certain industries, like medical devices and aerospace, have strict dimensional requirements. Inspection verifies parts comply with these regulations.

Improves Efficiency and Low Costs

By catching errors early, dimensional inspection prevents wasted materials and production delays, ultimately reducing manufacturing costs.

Frequently Asked Questions (FAQs)

What is the significance of Size Recognition in technology?

Size recognition plays a crucial role in various industries, enabling precise measurements and ensuring accurate outcomes for improved efficiencies.

How does Machine Vision revolutionize industrial processes?

Machine Vision integrates advanced technologies like LIDAR and Computer Vision to enhance automation, quality control, and productivity in diverse applications.

Why choose Prescient Technologies for Image Processing solutions?

Prescient Technologies excels in providing top-notch Image Processing services, leveraging Depth Perception and Shape Analysis for unparalleled results.

Ready for Superior Quality?

Let us to enhance your manufacturing process.

Key Features

Precise Object Measurement

Write impactful descriptions highlighting the accuracy of your technologies (e.g., "Measure objects down to micrometers with our advanced laser scanning systems").

Innovative 3D Measurement

Emphasize the benefits of comprehensive 3D analysis for complex shapes and objects.

Efficient Shape Analysis

Focus on streamlining workflows with automated shape recognition and analysis powered by computer vision and image processing.

Dimension Inspection in Different Industries

Manufacturing

Finds surface defects, assembly errors, and misaligned parts.

Electronics

Inspects circuit boards, solder joints, and semiconductor wafers.

Automotive

Detects paint flaws, scratches, and structural issues.

Pharmaceuticals

Checks packaging, labels, and tablet quality.