Defect Detection

Your Gateway to Zero-Defect Manufacturing

Accelerate Your Production with Intelligent Defect Detection

According to the American Society for Quality (ASQ), defects cost manufacturers almost 20% of their total sales revenue.

In today’s competitive manufacturing landscape, maintaining high-quality standards is paramount. Our innovative defect detection solutions empower you to identify and eliminate imperfections early in the production process, minimizing waste and maximizing efficiency.

Maximize Quality Assurance

with State-of-the-Art Defect Detection

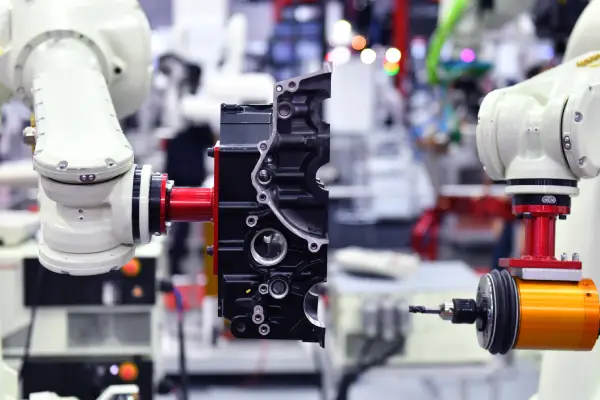

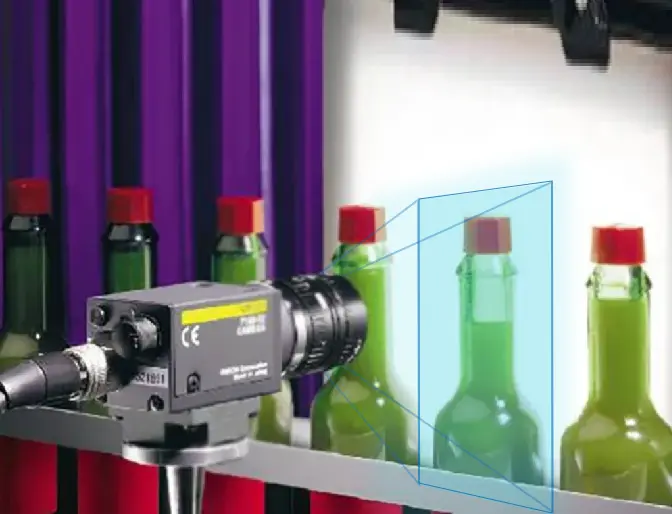

Automated Scanners

High-speed, non-contact scanners utilize advanced technologies like machine vision and AI to detect surface defects with exceptional accuracy.

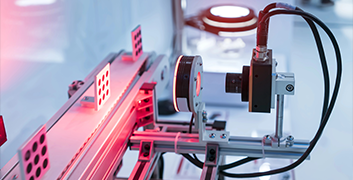

Optical Laser Systems

Employ laser light for precise dimensional measurements, identifying even the slightest deviations from specifications.

Thermal Imaging Cameras

Detect temperature variations that might indicate internal defects or potential overheating issues.

Benefits

- Enhanced Quality Control: Eliminate defective products from reaching your customers, boosting brand reputation and customer satisfaction.

- Increased Production Efficiency: Early defect detection minimizes rework and wasted materials, streamlining your production process.

- Reduced Costs: Lower overall production costs by preventing defective products and minimizing rework needs.

- Improved Data-Driven Insights: Our solutions can collect valuable data on defects, helping you identify trends and implement preventive measures.

Benefits of Defect Detection

- Enhanced Quality Control: Eliminate defective products from reaching your customers, boosting brand reputation and customer satisfaction.

- Increased Production Efficency: Early defect detection minimizes rework and wasted materials, streamlining your production process.

- Reduced Cost: Lower overall production costs by preventing defective products and minimizing rework needs.

- Improved Data-Driven Insights: Our solutions can collect valuable data on defects, helping you identify trends and implement preventive measures.

Enhanced Quality Control

Eliminate defective products from reaching your customers, boosting brand reputation and customer satisfaction.

Increased Production Efficiency

Early defect detection minimizes rework and wasted materials, streamlining your production process.

Reduced Costs

Lower overall production costs by preventing defective products and minimizing rework needs.

Improved Data-Driven Insights

Our solutions can collect valuable data on defects, helping you identify trends and implement preventive measures.

Benefits of Defect Detection

Why Choose Prescient Technologies for Defect Detection?

Industry-Leading Technology

We stay at the forefront of defect detection innovation, providing you with the most advanced solutions available.

Scalable Solutions

Our systems are designed to adapt to your specific production line needs and grow with your business.

Expert Support

Our dedicated team provides comprehensive support to ensure successful implementation and ongoing optimization.

The Ultimate Guide to Defect Detection in Manufacturing

Defect Detection in Different Industries

Manufacturing

Finds surface defects, assembly errors, and misaligned parts.

Electronics

Inspects circuit boards, solder joints, and semiconductor wafers.

Automotive

Detects paint flaws, scratches, and structural issues.

Pharmaceuticals

Checks packaging, labels, and tablet quality.

What is defect detection in manufacturing?

Al defect detection uses advanced algorithms and machine learning techniques to automatically identify defects in manufacturing processes with high accuracy and efficiency.

Why choose Prescient Technologies for surface detection?

Prescient Technologies offers cutting-edge solutions for surface detection using innovative technology and expertise to enhance manufacturing quality and productivity.

Why is defect detection important in manufacturing?

Defect detection is important because it ensures that products meet quality standards and specifications, reduces waste and rework, and maintains customer satisfaction. Detecting defects early in the manufacturing process can save costs and prevent defective products from reaching the market.

What industries commonly use defect detection systems?

Defect detection systems are used in various industries, including: Automotive: For inspecting parts and components to ensure safety and reliability. Electronics: For checking circuit boards and electronic components for defects. Aerospace: For ensuring the integrity of critical components. Pharmaceuticals: For inspecting packaging and labeling to ensure compliance with regulations. Food and Beverage: For ensuring product safety and quality.