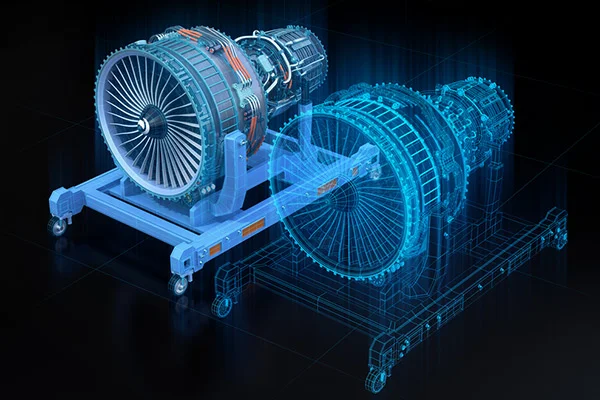

Digital Logbook

Unlock Efficiency and Streamline Operations with

our Digital Logbook Solution

Features Of The Digital Logbook

Features Of The Digital Logbook

Web-based Platform

Our Digital Logbook is accessible anytime, anywhere. Whether you prefer on- premises or cloud deployment, our platform provides the flexibility to suitHighlighting how Digital Thread saves time and resources by eliminating manual data entry and transfer, allowing employees to focus on more value-added tasks your specific needs.

Customizable Checklists

Tailor your checklists to fit your unique requirements. With our platform, you can easily create and configure checklists, define the order of checklist items, and provide additional instructions for each step.

Digital Recording of Information

Say goodbye to stacks of paper logs. Our solution enables seamless digital recording of information, streamlining the process and eliminating the risks associated with paper-based systems.

Checklist Approval Workflow

Ensure accuracy and compliance with our checklist approval workflow. Define the appropriate review and approval processes, enhancing accountability and control.

Instant Access to Information

Retrieve your data in an instant. Our platform offers real-time availability of recorded information, empowering you with quick access for analysis, reporting, and audits.

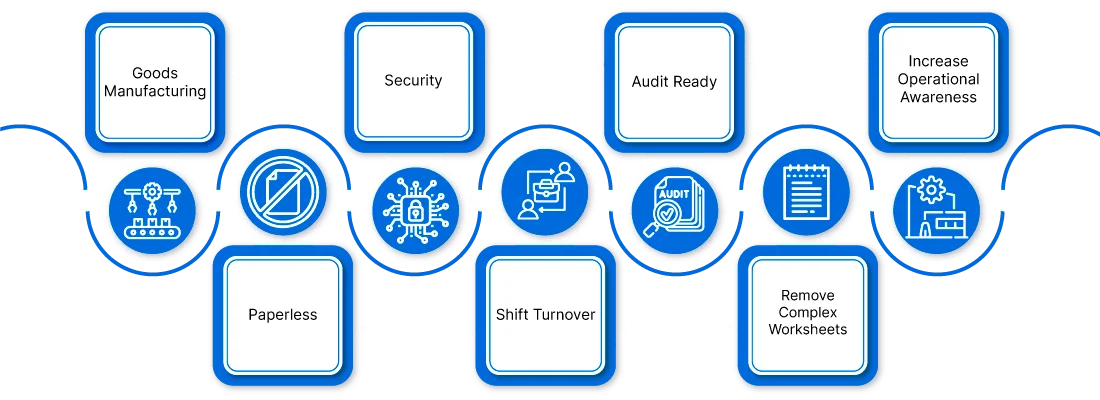

Benefits of Digital Logbook

Request a Demo For Operational Excellence

Digital Logbook Operation Rules

Functional Administrator

- Defines production lines and workshops

- Defines systems users and roles

- Configures different masters and checklists

Operator

- Views schedule

- Files checklist

- Views filled checklist

Line Incharge

- Approves filled check by operator

- Files checklist for production lines

- Monitors summary and reports

- Defines checklist-schedule for workstations

Process Incharge

- Configures different masters and checklist.

- Defines checklist-schedules.

- Files checklist for plant if applicable.

- Monitors reports and expectations from filled checklist.

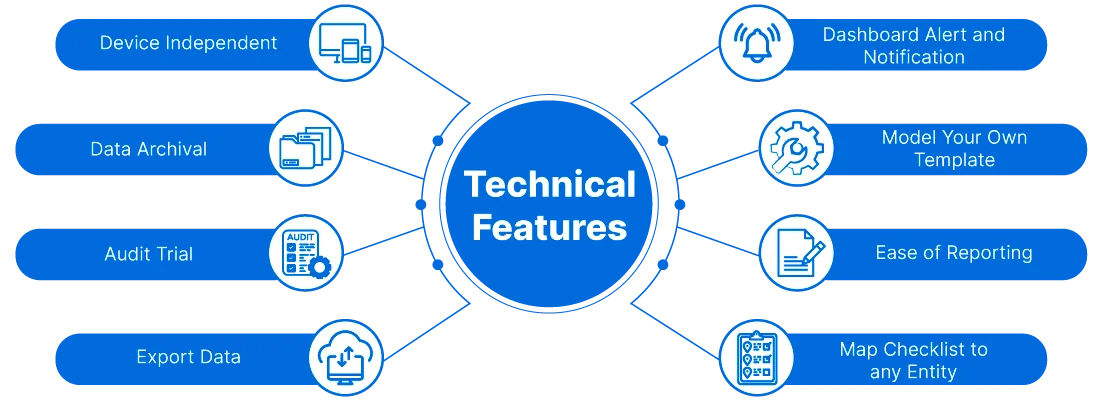

Technical Features

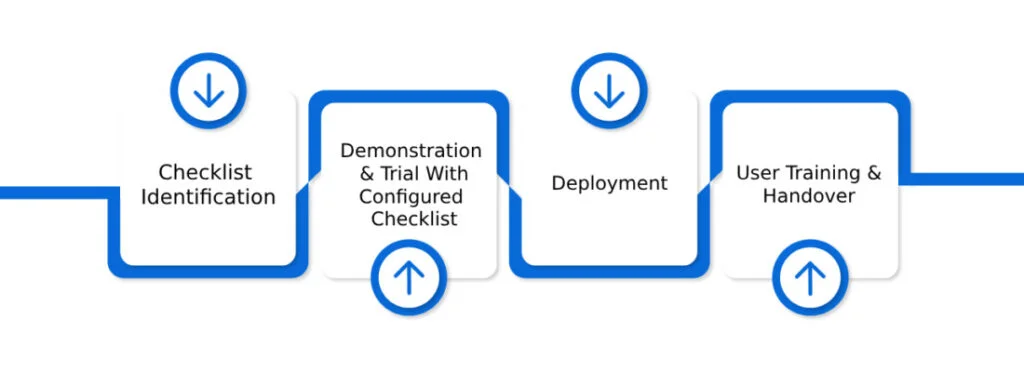

Digital Logbook Implementation

POPULAR NEWS

Featured Posts

- April 7 2025

- SRV support

Prescient Technologies Unveils New Brand Identity Reflecting Its Vision

Pune, India – 07/04/2025 – Prescient Technologies, a leading provider of advancedtechnology solutions and digital transformation services, today announced the launch ofits refreshed brand identity. The new look and messaging reflect Prescient’s renewedpurpose and evolving role as a future-forward, innovation-driven partner to globalindustries. At the heart of the new identity is a bold, modern logo with a standout orange dot on the“i”—symbolizing the spark of insight, creativity, and human-centric thinking that definesPrescient. The refreshed color palette and clean typography convey trust, clarity, andforward momentum. The refreshed identity is built on four strategic brand pillars—Integrity, Innovation,Infinity, and Impact—represented by the letter “i” in the logo. These pillars reflectPrescient’s approach to building long-term value and lasting partnerships: “These four pillars are not just values—they are the lens through whichwe deliver every solution,” said Deepti Waghmare, Director – Admin, Legal and HR. “Integrity means we stay transparent and accountable. Innovationreflects our passion for bold thinking. Infinity shows our belief inlimitless potential. And Impact is our commitment to real, measurableoutcomes.” said Deepti Waghmare, Director – Admin, Legal and HR. “Prescient has always stood for deep expertise, reliability, andforesight,” said Pravin Waghmare, CEO of Prescient Technologies.“With this new identity, we are embracing the future while staying trueto our core. It reflects how we approach every challenge, every solution, and every relationship.” “This new brand is a reflection of the evolution our customers areseeing in us,” said Ram Deshpande, VP – Sales and Marketing. “Itcommunicates who we are today—agile, future-ready, and deeply committed to our clients’ success. Our brand now mirrors the energy and ambition that drives Prescient forward.” With over two decades of technology excellence, Prescient is poised to accelerate itsglobal reach, expand digital services, and continue empowering organizations acrossmanufacturing, industrial automation, and enterprise software landscapes. Logo Decoded The Prescient logo blends simplicity with significance. Its clean, rounded typographyreflects a modern and approachable personality, while the calming blue symbolizestrust, reliability, and depth of expertise. The standout orange dot on the “i” adds a sparkof creativity—representing insight, agility, and the human touch at the heart of everysolution.The letter “i” in the logo carries deeper meaning—it embodies Prescient’s fourfoundational pillars: 1. Integrity: We uphold transparency, honesty, and accountability in everyrelationship and every solution.2. Innovation: We constantly push boundaries, embrace new ideas, and craftsolutions that shape the future.3. Infinity: Our thinking, solutions, and ambitions are limitless, reflecting our beliefin continuous evolution and boundless possibilities.4. Impact: We focus on delivering meaningful outcomes—creating real value forour clients, communities, and industries. Together, these elements form a bold, balanced, and forward-movingidentity—capturing Prescient’s unwavering spirit and purpose Media Contact: marketing@pre-scient.com

Read More- January 13 2025

- systemadmin

Ecommerce Product Configurator: Everything You Need To Know In 2025

The ecommerce industry will go through a remarkable transformation in 2025. It is driven by digital innovation and changing consumer expectations. Personalisation has become the new norm as customers increasingly seek tailored shopping experiences. At the heart of this trend are ecommerce product configurators. They are powerful tools that allow consumers to customise products in real-time. These configurators are revolutionising both B2B and B2C commerce. They are effectively closing the gap between customer preferences and business offerings. It is very clear in the fashion and automotive industries. Here, visual configurators have emerged as indispensable tools. They are increasing customer engagement and enhancing sales performance. What Is an Ecommerce Product Configurator? An e-commerce product configurator is a digital interactive tool on an ecommerce website. It enables customers to customise products before buying. Key Features Benefits The Role of Product Configurators in Ecommerce Product configurators meet the customer expectations of personalisation and interactivity. Expectations and Offerings In an era where consumers seek more control, configurators allow businesses to adapt their products to varied customer preferences. Industries Leveraging Configurators Top Features of Modern Product Configurators The latest product configurators incorporate advanced technology to provide seamless user experiences: These features make configurators valuable tools for improving customer satisfaction and operational efficiency. How Product Configurators Drive Sales Growth Visual configurators have a direct and measurable impact on sales performance: Case Studies: Most companies report a 20%–30% conversion rate increase and up to 50% growth in average order values after using configurators for engineering process automation. Overcoming Implementation Challenges While configurators have much potential, their implementation is not simple: Solutions Future Trends of Ecommerce Product Configurators in 2025 The future of ecommerce product configurators will continue changing, with these trends influencing its future: Conclusion In 2025, ecommerce product configurators will be a necessity for businesses seeking to stay competitive. These tools represent a significant leap forward in ecommerce innovation. With increasing consumer expectations, businesses have no choice but to use configurators in order to meet the interactivity and personalisation requirements that their customers are demanding. By doing so, they will increase engagement sales and lead in the fast-paced ecommerce landscape. Revolutionise Your Engineering Processes with Prescient’s Digital Thread Effectively link each aspect of your engineering activities through the Prescient Technologies Digital Thread. With this innovative technology, it enables organisations to automate workflows, eliminate inefficiencies, and increase collaboration through product lifecycles. Whether it is design iteration, real-time data integration, or traceability from concept to production, Prescient’s Digital Thread delivers unparalleled precision and agility. Join the future of engineering process automation, where innovation harmonises with efficiency. Start your journey to operational excellence. Explore Prescient’s Digital Thread today!

Read More- January 13 2025

- systemadmin

Types of Energy Management Systems

Sustainability is now a business necessity. Energy optimisation has become critical for companies across sectors. Rising energy costs and environmental regulations have propelled the adoption of Energy Management System Software. These systems reduce costs and contribute to a greener planet. They ultimately minimise energy waste. Knowing each type of energy management system is crucial to helping businesses improve efficiency and succeed. Let’s look at the applications and the value propositions these systems uphold. What Are the Four Types of Energy Management? EMS belongs to diverse use applications. These mainly include the four types described next: 1. Building Energy Management Systems (BEMS) BEMS optimises energy usage in commercial and institutional buildings. Example: A corporate office using BEMS can reduce energy consumption by 20%. It can change HVAC settings based on occupancy. 2. Industrial Energy Management Systems (IEMS) IEMS is tailored for manufacturing and production facilities. It focuses on reducing energy-intensive operations. Example: 25% of energy usage can be reduced in a factory through predictive maintenance. 3. Residential Energy Management Systems (REMS) REMS for home and housing complexes, wherein smart devices can automatically control the usage of energy Example: A homeowner can save 10% on energy by using a REMS app. The app can time the running of high-energy appliances during off-peak hours. 4. Utility Energy Management Systems (UEMS) UEMS is for utility companies that focus on the grid energy distribution level. Example: A utility company can use UEMS to control peak demand during a heatwave, avoiding power cuts while still being energy efficient. What Are Examples of Energy Management Systems? Energy Management Systems have been applied in many industries: Hypothetical Case: A logistics firm using EMS to monitor and manage warehouse energy usage will reduce its energy costs by 30%. Such is the direct business value offered by the system. How do you select the appropriate EMS? In essence, the features offered by EMS must match the business’s requirements. Some factors that dictate the selection are scalability, real-time analytics, and ease of integration. What Are the Components of Energy Management Systems? Energy Management System Software consists of three essential elements: 1. Real-Time Monitoring 2. Automated Controls 3. Energy Forecasting Value Proposition: These parts collectively reduce operational expenses, ensure environmental compliance, and support sustainability. For example, digital logbooks can record and analyse factory data online, saving thousands of dollars annually in paper resources. What is the Difference Between EMS and SCADA? EMS and SCADA are both critical components of modern industrial operations. However, they serve different purposes: Energy Management System (EMS) SCADA Synergy: EMS and SCADA integrate energy-specific information with comprehensive process control. In doing so, businesses can take full advantage of their resources in a way that leads to enhanced efficiency. How Do EMS Systems Add Value? Energy Management Systems offer quantifiable benefits: 1. Cost Efficiency 2. Improved Operational Efficiency 3. Sustainability Objectives Conclusion Energy efficiency is increasingly becoming a competitive differentiator. Hence, energy management systems are essential for businesses that want to be ahead of their competitors. Integrating digital logbooks and energy forecasting further enhances their effectiveness. Adopting an EMS pays off in the long run. They can help reduce costs and future-proof operations. Transform Your Energy Management with powerCONNECT Take charge of your energy use with powerCONNECT, the latest Energy Management System Software from Prescient Technologies. It is designed to maximise energy usage and achieve sustainability goals. Its features include real-time monitoring and predictive analytics. Both these latest technologies are available with a customisable dashboard. Power up your operations with actionable insights and unmatched efficiency. powerCONNECT is the scalable solution to stay competitive in today’s energy-conscious world. Get on the right path toward your goal of smarter and greener operations. Learn more about how Prescient Technologies can help. Schedule a demo today!

Read MoreWhat is Digital Logbook?

A Digital Logbook is an electronic system used to record, store, and manage data entries and logs digitally. It replaces traditional paper logbooks, allowing for real-time data updates, secure storage, and easy access to information. Commonly used in industries like manufacturing, healthcare, and logistics, digital logbooks enhance productivity by automating data entry, tracking activities, and ensuring compliance with regulatory standards. They are designed to improve efficiency, accuracy, and communication within organizations.

What are the benefits of using a digital logbook over a traditional paper logbook?

Digital logbooks offer real-time updates, automation, better data accuracy, secure storage, and easy accessibility, improving efficiency compared to traditional paper logbooks.

How secure is the data stored in a digital logbook, and what measures are in place for data protection?

Digital logbooks employ encryption, access controls, and regular backups to protect stored data, ensuring security and regulatory compliance.