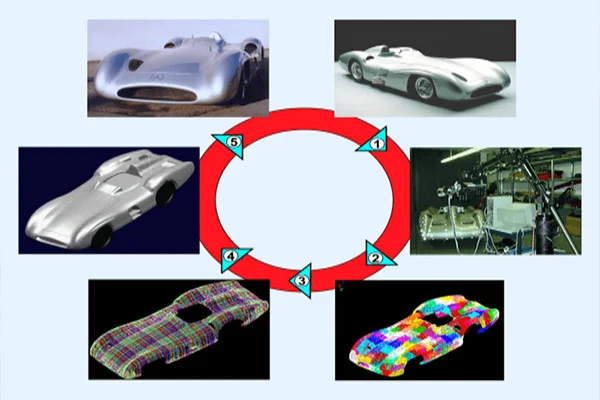

The Reverse Engineering process

Sometimes, situations arise where you don’t have access to a part’s original design documentation from its original production. This might be due to the absence of the original manufacturer altogether or stoppage on the production itself. Reverse engineering empowers us to analyze a physical part and explore how it was originally built to replicate, create variations, or improve on the design. The goal is to ultimately create a new CAD model for use in manufacturing. Let us take a look at the steps involved in reverse engineering. Commonly, it involves careful executions of the following steps: Scanning The first step involves using a 3D scanner for collecting the geometric measurements and dimensions of the existing part quickly and accurately using projected light patterns and camera system. Generally, the types of scanners used for such execution are blue light scanner, white light scanner, CT scanner and /or laser scanner. The former two captures the outward dimension and measurements while the latter two is capable of scanning the entire inside out. Point Cloud Once a certain part is scanned, the data gets transformed in the form of point clouds. Point cloud is a 3D visualization consisting of thousands or even millions of points. Point clouds define the shape of a physical system. Meshing/Triangulation This stage serves involves conversion of point clouds to mesh (STL or Stereolithographic format). Mesh generation is the practice of converting the given set of points into a consistent polygonal model that generates vertices, edges and faces that only meet at shared edges. Common software tools used to merge point clouds are Polywords, Geomatics, Image Ware, MeshLab. The meshed part is then run for alignment in the mentioned software tools. Parametric/Non-parametric Modeling After the meshed part is aligned, it goes through either of two stages. The first option involves applying surface modeling on meshed part in tools such as Polyworks. It results in the generation of non-parametric model (IGES or STEP format). An alternate option is creating a sketch of the meshed part instead of putting it through surfacing. This work-process is known as parametric modeling (.PRT format). For a non parametric model, predicting future data is based on not just the parameters but also in the current state of data that has been observed. For a parametric model to predict new data, knowing just the parameters is enough. CAD Modeling The next stage consists of transferring the data through CAD software tools such as NX, Catia, Solidworks, Cero etc., for applying functions such as ‘stitch’, ‘sew’, ‘knit’, ‘trim’, ‘extrude’, ‘revolve’ etc for creation of 3D CAD model. Inspection This stage includes visual computer model inspections and alignment of the merged models against actual scanned parts (STL) for any discrepancies in the geometry as well as dimensions. Generally, inspection is carried out by using tools such as Polyworks or Geomagic. Reverse engineering inspection provides sufficient information to check tolerances, dimensions and other information relevant to the project. Documentation Documentation of 3D stage model depends solely on one’s technical/business requirements. This step is about converting 3D model to 2D sketch, usually with the help of tools such as inventor or Isidra/Coral draw, citing measurements which can be used for reference in the future.

Read MoreWhat is Reverse Engineering ?

Let us start with an example. One day you get into your garage and find on the workbench a ‘black box’. Stricken by curiosity, you build up an urge to discover what it ‘is’ and what it ‘does’. You start with an inspection of the box’s dimensions, color. Then you try to find its purpose and then how it operates. Not satisfied, you try to open it, break it apart, piece by piece in an attempt to understand what each component does and build up a pattern of how they would all interact together as one system. Finally you reach the end of your inquisition. You now fully (or partially) understand the box. This very approach is termed as Reverse Engineering.Reverse engineering, also known as back engineering, is the process where a man-made object is dismantled completely to reveal its architecture, design or to extract knowledge from the object about its functioning and structural integrity. Why do you need Reverse Engineering? There might be innumerable reasons to adopt reverse engineering process. Some of the common cases are as follows:

Read MoreReverse Engineering vocabulary

3D Scanning – The process of collecting 3-Dimensional data from physical object through a variety of data acquisitions devices. 3D to CAD: The process of converting 3-Dimensional point to a dimensionally defined graphic model. Accuracy: The extent of how close a measurement is to the recognized true value. Annotation Models: A digital model containing specific coordinate locations verifying deviations from nominal data. AS IS CAD: A CAD model that represents actual manufactured parts rather than a designed CAD model. CAD (Computer-aided design): The use of computer technology to assist in the creation, analysis, or modification of a design. CAM (Computer Aided Manufacturing): The use software that can support both machine tools and 3D CAD modeling capabilities. Cone beam: A conical-shaped x-ray beam that produces two dimensional images of an object. Design intent: The process of taking a manufactured part into account with inherent errors and modifying the same till it is true. GD&T (Geometric Dimensioning and Tolerancing): System of languages and symbols used for defining and communicating engineering tolerances. Hand held scanner: Portable camera that is used for capturing 3D imagery of objects with a laser or structured light based. Hybrid Model: Combining two different modeling processes to accurately define 3D geometry. Laser Scanner: A device used to capture 3D surface geometry, consisting of a laser output and a sensor to interpret the data. LIDAR: A combination of the words: “Light” and “RADAR.” A LIDAR scanner employs RADAR’s technique of emitting a signal and measuring distances to objects based off of the signals reflection. Long Range Scanning: Acquiring data at expansive distances from hundreds of feet away to miles away. Data can be captured through a variety of devices including LIDAR, Time of Flight and phase shift scanners. Modeling: Digitally creating 2D or 3D object using CAD or data manipulation software, such as Polyworks, Geomatics or Solid works. NanoCT: Capturing images using CT (Computed Tomography), with a resolution of the images defined in nanometers. Parametric Model: A sketch driven model that builds a design tree that can be opened in a CAD environment and allows the operator to manipulate the model. Parametric Modeling: This process is taking 3d scan data and through the use of design tools, creating a sketch driven model with consistent relationships between features in the feature tree. Phase Based Scanners: LIDAR Scanners that take measurements by sending laser pulses towards an object and measuring the phase shift of the pulses’ reflection off of the object. Point Cloud: A set of points defined by X, Y, and Z coordinates that represent the external surfaces of an object. Prismatic Modeling: Creating CAD geometry using basic geometry shapes, i.e. planes, cylinders, cones etc, to define correct shapes of the 3D geometry. Re-Engineering: The process of modifying an existing part or assembly of parts digitally to improve its performance or use. Repeatability: The variation in measurements taken with the same piece of equipment, under the same conditions, across multiple tests. Reverse Engineering: The process by which a man-made object is dismantled to reveal its architecture, designs, or to extract knowledge from the object in order to know about its functioning and structural integrity. SCAN to CAD: The process of collecting 3D data using 3D scanning hardware and converting the dimensional data to CAD format using a variety of software packages. 2D Drawings / Schematics: A 2D print that describes the physical characteristics of an object, how it should be made, assembled, handled, etc. These can be used to provide basic dimensional values to define its function. Sectioning: The process of creating 2D profiles through sections of an object. Short range scanning: A process used to collect dimensional data in 3D space from short ranges. Solid Modeling: Defining an object with CAD tools such as extrudes, revolves, sweeps, etc. A solid model is enclosed and is said to have mass and volumetric values can be calculated. Surface Model: An objects exterior skin defined by CAD features or NURBS surfaces. Triangulation Scanner: Projecting a known pattern of light grids or fringe onto an object in order to calculate surface geometry by analyzing the distortions of the pattern. White Light Scanner: A 3D camera projecting a known pattern of light grids or fringe onto an object in order to calculate

Read MoreNPD/ID vocabulary

Bill of materials (BOM): A table containing a list of the components and the quantity of each required to produce an assembly. Brief: Instructions and requests provided to design team prior to the commencement of a project. Business analysis: The practice of identifying business needs and determining solutions to business problems. Commercialization: The process of introducing a new product or production method into the market. Concept design: An early phase of design process, where the broad outlines of function and form are articulated. Ergonomics: Application of principles that consider the effective, safe and comfortable use of design by humans. Ideation: Idea generation or brainstorming. Industrial design: The process of designing products used by millions of consumers around the world. Market research: An organized effort to gather information about target markets or consumers. New product development (NPD): The complete process which involves transformation of a market opportunity or product idea into a product available for sale. New Product Introduction (NPI): New product introduction is the complete process of bringing a new product to market. Patent: An exclusive right granted to an inventor by a sovereign authority, for a specified time period. Pilot Run: An initial small production run produced as a check, prior to commencing full-scale production. Prototyping: An early sample, model, or release of a product built to test a concept or process or built to act as a commodity to be replicated or learned from. Sketch: An image that is quick to generate and does not contain complete detail. S.W.O.T: Analysis framework for a company relative to its competitors, market, and industry: Strengths, Weaknesses, Opportunities & Threats. Test marketing: An experiment conducted by companies to check the viability in the target market before full scale manufacture.

Read MoreWhat is a Patent?

Before you get an answer to that question, take a moment to ask yourself – what are the advantages of having a real estate property to your name? On similar terms, patent is an intellectual property that has all the advantages stated above and one needs to claim it on his/her name. A patent is the granting of property right to an inventor, by a sovereign authority. This grant provides the inventor exclusive rights to the design, or invention for a designated period (usually 20 years), in exchange for a comprehensive disclosure of the invention. Patent process is generally invoked when the product/process I provides a new way of doing something, or offers a new technical solution to an existing problem. Filling for a patent comes with many advantages. Understanding the pros can enable an inventor to make an informed decision. Advantages of Patents

Read MoreThe New Product Development Process

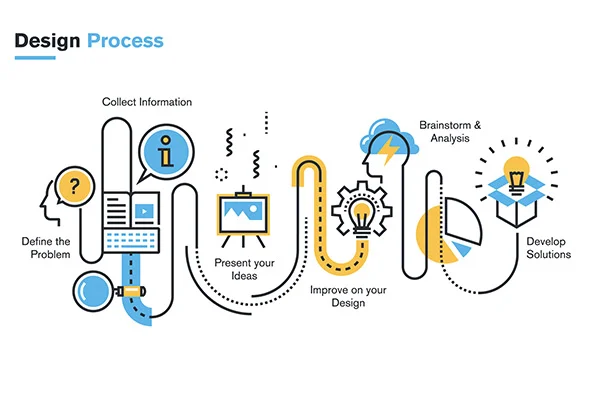

You might be a seasoned design professional thinking “What do my bosses sit around and do all day while I do the real design work”. This section outlines and explores the various early stages of the industrial design process that a product goes through. It does serve as a reasonable account of the overall and general product design process. Ideating or initial ideas Before any design work can begin on a product, there must first be a definition of what the product or product line might be. The idea’s genesis can be many factors such as: Keeping up with the competition Staying ahead of the competition should always be the primary goal for any business. And increased competition is one of the major reasons leading to go for new products development. New products give us a competitive advantage over our rivals. Every firm struggles to fulfill and retain consumers by offering exceptional products. To offer more competitive advantage over the other and to satisfy consumer needs more effectively and efficiently, the product innovation seems to be needed. Consumer demand – Reviews & feedbacks from the customers or even their ideas can help companies generate new product ideas. Internal sources – Companies provide incentives and perks to employees who come up with new product ideas Market research – Companies constantly review the changing needs, requirements and trends of the market by conducting plethora of market research analysis. Competition – Competitors SWOT analysis helps companies to generate ideas. Idea screening An idea can be excellent, good, moderate or very bad. Once a suitable product opportunity has been identified, a specification document or design brief is created to define the product. It is usually created by the higher management of a company who’ll have access to information, such as budgeting and buyer/seller feedback. This step involves filtering out the good and feasible ideas which maintains the technical integrity while staying within realistic cost expectations. Features such as a mechanical specification or a reference to an existing invention the product might be based upon, are outlined. Expectations, uses, and underlying intelligence associated to the product are included as well. Electronics, including sounds, lights, sensors, and any other specific inputs, such as colors and new materials may also be mentioned. Finally, a few reference sketches or photo images can be added to convey a possible direction. Concept design & development All ideas that pass through the screening stage are turned into concepts for testing purpose. A concept is a detailed strategy or blueprint version of the idea. In most companies, designers work up a design brief or product specification that guides their designs. It’s the designer’s role to make these ideas a reality. A professional designer has the ability to provide a large variety of designs in a quick and efficient manner. Many people can draw one or two ideas, but when asked to elaborate they often fall short. What separates the true design professional is depth and breadth of their presented ideas and vision in a clear and concise manner. Concept design generally means the use of hand-drawn or digital sketches to convey what’s in a designer’s mind onto paper or a screen. Business analysis A detailed business analysis is required to determine the feasibility of the product. This stage determines whether the product is commercially profitable or not, whether it will have a regular or seasonal demand and the possibilities of it being in the market for the long run. Modeling With the help of 3D modeling software (CAD – Computer Aided Design), the ideas/concept is rendered a shape, thereby creating a 3D model. The technical and engineering team has the biggest workload during this phase. These 3D models will often show up problematic areas where the theoretical stresses and strains on the product to be developed will be exposed. If any problem persists, it is a best phase of product development to handle the design errors and come up with modifications to address the same. Prototyping & pilot runs (preliminary design stage) In this stage, prototypes are built and tested after several iterations and pilot run of the manufacturing process is conducted. This stage involves creating rapid prototypes for a concept that has been deemed to have business relevance and value. Prototype means a ‘quick and dirty’ model rather than a refined one that will be tested and marketed later on. Adjustments are carried out as required before finalizing the design. Test marketing Apart from continuously testing the product for performance, market testing is also carried out to check the acceptability of the product in the defined market and customer group. It is usually performed by introducing the new product on a very small scale, to check if there are any shortcomings. This helps to know in advance, whether customer will accept and buy this product on launching in the market. Test marketing is a powerful tool indeed. New product launch This is the final stage in which the product is introduced to the target market. Production starts at a relatively low level of volume as the company develops confidence in its abilities to execute production consistently and marketing abilities to sell the product. Product manufacturing expenses depend on the density of the product, if there are numerous parts, material selection etc. The organization must equip its sales and customer service entities to address and handle queries. Product advertisements, website pages, press releases, and e-mail communications are kept on standby on the launching day. Product development is an ever evolving fluid process and cannot be summed up in a few steps. The entire procedure sees insertion of additional stages or even eviction of a crucial part, depending on the nature of the project. Each group of professionals, whether designers, engineers or marketing, sales; has their role to play in this methodology. It is the company’s responsibility to continuously monitor the performance of the new product.

Read MoreImportance of Product Development(NPD) & Industrial Design(ID) for a business

ver the first fiscal quarter of 2018, Apple accelerated investments in research and development operations spending more than $3.4 billion on new hires and initiatives which will keep the company competitive in a fast-paced tech market. Product development is like the gasoline that keeps the wheels rolling. But what drives companies to spend valuable resources such as time, money, human capital, etc. on new product development? And why is it so important? Here are five reasons: Value for customers The primary reason for any new product development is to provide value to its customers. The increasing demands of customers for innovation & new technology calls for the need to develop new or existing products. Otherwise, there is no reason to pour in huge amounts of money in the first place. Keeping up with the competition Staying ahead of the competition should always be the primary goal for any business. And increased competition is one of the major reasons leading to go for new products development. New products give us a competitive advantage over our rivals. Every firm struggles to fulfill and retain consumers by offering exceptional products. To offer more competitive advantage over the other and to satisfy consumer needs more effectively and efficiently, the product innovation seems to be needed. Changing markets Today’s market is more dynamic as compared to the past; it keeps on changing due to the wide variety of customer needs, all thanks to increased literacy rate, globalized market, heavy competition, and availability of a number of substitute. Consumers are constantly evolving which means their tastes and preferences change with them. It is the changing consumer behavior that drives the innovation and development of products. Plus, it also counters seasonal fluctuations. Explore technology Just as consumer trends drive new products, advances in technology drives companies to invest in new products. If your company has not upgraded its technology arsenal for ten years, count yourself to be at the last one in the queue within a few years. Reputation and goodwill Building image and reputation as a dynamic innovation and creative firm boosts a company’s legacy. The new product development is approached. Company desires to convince the market that it works hard to meet customer’s expectations. In fact, company developing new products frequently has more reputation and can easily attract customers. Industrial design is a very crucial part of the entire new product development process. We are aware of the fact that industrial design develops aspects of a product that create emotional connections with the user. It integrates all aspects of form, fit, and function, hence optimizing them to create the best possible user experience. Industrial design’s role in product development process is to establish the design language of a product, as well as the corporate branding and identity. How successfully a company is able to carry out development or modification, incorporating the ergonomics aspect, can often determine the success of a product in the market. Firms that leave industrial design to the end of the engineering lifecycle, or out completely will struggle to find success in consumer-driven markets.

Read MoreWhat is Industrial Product Design?

Table of content What is Industrial Product Design? What does an Industrial Designer do? Every product you have in your home and interact with is the outcome of a design procedure. After long hours of planning, sketching, rendering, and 3D modeling, all those products have come into being. Not to mention the numerous prototypes and testing, it has finally hit the shelves. The ideation and the procedure to develop a particular product is collectively called the Industrial Product Design process or simply ‘Industrial Design’ (ID). Industrial Product Design is the professional practice of conceptualizing and designing products, which are manufactured through mass production techniques, and eventually used by millions of people worldwide every day. An industrial product design process incorporates inputs from diverse domains such as ergonomics, form studies, studio skills, advanced cad, research methods, design management, materials & manufacturing techniques, and social sciences. What does an Industrial Designer do? An industrial designer’s purpose is to emphasize— the appearance of a product, the functioning, how the product is manufactured, and the value & experience it provides for users. Their sole intent is aimed at improving your life through design. Pioneered by industrial engineers and designers, industrial product design has carried manufacturing processes through a significant transformation, without which we would not have the same living standard we have today. Industrial design optimized and streamlined mass production while bringing in artistic functionality and ergonomics, giving back aesthetically pleasing products to the masses. Industrial product designers affect our daily lives more significantly than we imagine. The prime goal of industrial product design is to increase the usability of a product while retaining pleasing aesthetics and improving already existing products. Nowadays, companies have multidisciplinary teams consisting of strategists, planners, user interface (U)I designers, user experience (UX) designers, engineers, graphic designers, branding professionals, etc. – all working for a singular goal, which is to bring you the best product you have never had before. Such a collaboration opens doors to new ideas and perspectives and allows room for the entire evolution of a great product. Industrial product designers collaborate with engineers, material scientists, manufacturers, and branding strategists to bring their creations to life. It takes months and sometimes years of designing, testing, reworking, and developing before the product finally hits the shelves. Industrial product design is an ever-evolving process that keeps changing with technology, market trends, and socioeconomic factors.

Read MoreWhat is New Product Development?

Often businesses confront consumer preferences, increasing competition and advances in technology; credits to a rapidly changing market scenario. Your business may need to capitalize on an opportunity with the sole intent of getting a monopoly on your respective sector. A common practice of companies is to engage in a process of understanding what their market wants, making smart product improvements, and developing new products that meet and exceed their customer’s expectations. This entire procedure can be termed as ‘New product development’ (NPD). New product development is the process which involves forming strategy, organizing requirements, generating concepts, creating product & marketing plan, evaluating and subsequent commercialization, thereby bringing a new product to the marketplace. ‘New products’ can be: This article explains the importance of NPD and Industrial Design which is a subset of NPD and describes the steps involved.

Read More