Image Processing

Image Processing Digital Image processing has variety of applications in the digitized world – viz inspection, security, medical diagnostics and so on. Image processing also forms a core part of machine vision, which is on the verge of automating tasks that conventionally relied on human vision and judgment. This topic introduces the basics of image representation in form of various color spaces, encoding of images and broad level image operations. It also touches on applications in various fields. Presenter Pravin WaghmareHarshada is part of Engineering Solutions group. Over past 3 years at Prescient, she has worked on various video and image processing projects, requiring investigations on various types of image manipulations and data extraction. This webinar will be a valuable resource for individuals and businesses looking to optimize their product design and manufacturing processes. Attendees will gain a thorough understanding of knowledge-based engineering and its advantages, including reducing errors, improving design quality, and accelerating time-to-market. The use cases presented will showcase the versatility of knowledge-based engineering across industries, including aerospace, automotive, and healthcare. By the end of the webinar, attendees will have a clear understanding of how to implement knowledge-based engineering and the best practices to follow. The Q&A session will provide an opportunity to ask specific questions and gain further insights into the topic. Don’t miss out on this opportunity to learn about knowledge-based engineering and take your product design and manufacturing process to the next level!

Read MoreCAx Software for Simulation and Analysis: Integrating Engineering Tools

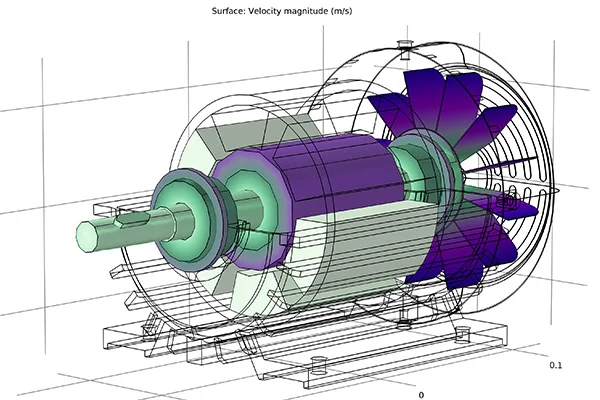

Table of content Introduction The Need for Simulation and Analysis in Engineering CAx Software: A Platform for Integration Benefits of Integrating Engineering Tools with CAx Software Challenges in Integrating Engineering Tools with CAx Software Emerging Trends in CAx Software Integration Conclusion Introduction Computer-aided design software has transformed engineering by speeding up the design process and allowing engineers to generate complicated models quickly. However, CAx has capabilities that go beyond design. Engineers can use CAx software for simulation and analysis to study the behavior and performance of designs before manufacturing. This article examines how engineering tools can be integrated with CAx software, highlighting the advantages, difficulties, and new developments. The Need for Simulation and Analysis in Engineering Analysis and simulation are essential components of the engineering design process. They enable engineers to assess numerous design options, spot potential issues, and enhance performance. Engineers can evaluate structural integrity, fluid movement, heat transfer, and electrical behavior. Engineers may improve the overall quality of their designs, lower costs, increase efficiency and make informed decisions. CAx Software: A Platform for Integration CAx software is an ideal platform for integrating simulation and analysis tools. Its extensive capabilities enable widespread use in the engineering industry. Engineers can seamlessly transition from design to analysis without complex data transfers or software interoperability challenges. They can incorporate these tools directly into the CAx environment. Benefits of Integrating Engineering Tools with CAx Software There are several benefits to combining engineering tools with CAx software. These range from incredible teamwork and increased design effectiveness to cost and time savings. Let’s get started and discover how using CAx software and engineering tools may improve your designs: Enhanced Design Iteration Engineers can perform virtual tests and experiments by integrating simulation and analysis tools with CAx software, allowing rapid design iterations. They can quickly evaluate design changes, assess their impact, and refine their models accordingly. This iterative process significantly reduces physical prototyping and testing time and cost. Improved Design Optimization Engineers can more efficiently optimize their designs with CAx software for simulation and analysis tools. They can use cutting-edge algorithms and optimization approaches to alter design parameters for optimal performance automatically. The process is based on predetermined criteria. This integration allows engineers to explore various design options and quickly find the best solutions. Accurate Performance Prediction Simulation and analysis tools integrated into CAx software give engineers accurate predictions of a design’s behavior and performance. Engineers can assess stress distribution, thermal behavior, fluid dynamics, and electromagnetic properties by replicating real-world conditions. This knowledge helps engineers identify potential weaknesses and make necessary improvements before manufacturing, ensuring better overall performance and reliability. Seamless Data Exchange Integrating CAx software for simulation and analysis tools ensures seamless data exchange between different engineering domains. Engineers can transfer design parameters, geometric information, and simulation results between various analysis modules within the CAx environment. This integration promotes collaboration, improves data consistency, and eliminates the need for manual data translation or re-entry, reducing the chances of errors. Challenges in Integrating Engineering Tools with CAx Software A unique set of difficulties arises while navigating the complex environment of CAx software integration with engineering equipment. Let’s look at some of the significant obstacles and possible solutions to get through them so that the integration process runs smoothly and successfully: Complex Software Architecture Integrating simulation and analysis tools within CAx software requires a complex software architecture that can handle the diverse requirements of different engineering domains. Software developers face significant challenges in ensuring smooth communication between CAx and analysis modules, data synchronization, and maintaining a user-friendly interface. Interoperability Issues Different vendors often develop CAx software for simulation and analysis tools, resulting in interoperability challenges. Standardization efforts, such as the STEP (Standard for the Exchange of Product Data) format, have helped mitigate these issues. However, further collaboration and standardization initiatives are required to ensure seamless integration and data exchange between software tools. Computational Requirements Simulation and analysis processes can be computationally intensive, requiring substantial computational resources. Integrating these tools within CAx software necessitates optimizing performance, memory management, and scalability to efficiently handle large and complex models. This challenge becomes more significant as engineers demand faster simulations and analyses to meet tight project deadlines. Emerging Trends in CAx Software Integration CAx software integration is changing due to some intriguing new trends. These developments rethink how engineers approach design and analysis and present new opportunities. Let’s investigate the most recent developments that are elevating CAx software integration to new levels: Cloud-Based Solutions Cloud computing offers a promising solution for CAx software integration by providing scalable computational resources and collaborative environments. Cloud-based CAx platforms enable engineers to access simulation and analysis tools remotely. It reduces the burden on their local machines and facilitates real-time collaboration among team members. Integration of Artificial Intelligence (AI) CAx software’s inclusion of AI algorithms improves simulation and analysis capabilities. AI can optimize designs, automate complicated operations, and increase the precision of predictions. Machine learning approaches might advise design alterations based on simulation findings. Advanced technical analysis and optimization are now possible thanks to the combination of AI and CAx software. Multi-Disciplinary Optimization Multi-disciplinary optimization features are being added to CAx software to address the increasing complexity of engineering systems. Engineers may optimize designs simultaneously for numerous domains because MDO integrates several analysis modules. Engineers may use this method to investigate intricate design spaces, weigh trade-offs between several disciplines, and produce comprehensive design solutions. Conclusion CAx software has significantly developed from a simple design tool to a complete simulation and analysis platform. Engineers can easily switch from design to analysis by integrating engineering tools into the CAx environment, streamlining the product development process. Enhanced design iteration, better optimization, precise performance forecasting, and seamless data interchange are some advantages of this connection. However, issues with software architecture, interoperability, and computational needs must be resolved to fully utilize the potential of CAx software for simulation and analysis. The future of CAx software integration looks bright with growing trends, including cloud-based solutions, AI integration, and multi-disciplinary optimization, promising even

Read More5 Ways Knowledge-Based Engineering (KBE) Can Streamline Product Development

Table of content Introduction 5 Effective Strategies to Streamline Product Development Through KBE Conclusion Introduction Companies always look for ways to enhance efficiency and optimize product development processes. Knowledge-based engineering helps manufacturing companies boost overall performance in today’s dynamic, technology-driven environment. It automates design, analysis, and decision-making by fusing engineering expertise with cutting-edge computational techniques. This article will examine five crucial ways of knowledge-based engineering that can speed up product development. Increased productivity, lower costs, and shorter time to market are the standout benefits of incorporating this technology. 5 Effective Strategies to Streamline Product Development Through KBE: Are you looking to streamline your product development process? Discover how Knowledge-based engineering (KBE) can revolutionize your approach with these five key strategies: Automated Design and Optimization One of the primary benefits of knowledge-based engineering is its ability to automate the design process. It captures and encodes engineering knowledge into rule-based systems to generate designs following predefined constraints and requirements. It eliminates repetitive manual design iterations, significantly reduces human error, and accelerates the entire process. You can leverage parametric modeling techniques to create design templates with adjustable parameters. These templates serve as the starting point for generating multiple design alternatives. Engineers can modify the parameters for the KBE system to adjust the design automatically. This iterative process encourages rapid exploration of design options without requiring manual modifications at each step. Additionally, the system integrates optimization algorithms to explore design spaces and identify optimal solutions. The system can define design objectives and constraints to refine the design and achieve the desired performance metrics iteratively. This approach saves, improves product performance, and reduces development time. Standardization and Reusability Knowledge-Based Engineering promotes standardization and reusability of design elements, components, and workflows. Organizations can establish a consistent design methodology across projects, departments, and locations by codifying engineering knowledge into reusable modules. This standardization ensures product quality and allows for the seamless transfer of knowledge between teams. This methodology accelerates the development process. Using KBE systems, you can create design libraries that act as repositories of verified and improved design solutions. These collections include modular elements, including CAD templates, simulation models, and 3D models. Engineers can use the components from these libraries to speed up and simplify their design processes. Reusing pre-validated components across many projects ensures consistency and dependability. Enhanced Collaboration and Knowledge Sharing Collaboration is crucial in product development, especially in large organizations or projects involving multidisciplinary teams. Knowledge-based engineering provides a platform for engineers from different domains to share and access engineering knowledge. Engineers can collaborate in real-time, exchange design information, and perform concurrent engineering tasks. They can also contribute their expertise to the overall product development process. KBE systems commonly include features like version control, document management, and communication tools. These capabilities assist engineers in collaborating on design projects and accessing the most recent design information. They can also offer their perspectives through this system. Engineers from various specialties like mechanical, electrical, and software engineering can collaborate and work seamlessly. It helps reduce communication gaps and also streamlines decision-making. Furthermore, KBE systems can capture and document the rationale behind design decisions. It helps preserve valuable engineering knowledge to share across the organization. Lessons from previous projects can be stored as design rules, best practices, and simulation models. It allows engineers to build upon existing knowledge. KBE enhances product development processes’ overall efficiency and effectiveness by facilitating knowledge sharing and collaboration. Optimize Performance and Efficiency Efficient design tools must perform at their peak to handle intricate 3D models, big assemblies, and computationally demanding activities. The main goal of CAD software development should be performance optimization. Reduce computing complexity and memory utilization by using algorithms and data structures. Use approaches like spatial indexing, effective mesh representations, and level-of-detail algorithms to ensure quick rendering and easy interaction with the CAD models. Utilize the power of contemporary hardware by using multithreading and parallel processing. You can use several CPU cores and GPUs for quicker computations. The user experience can be further improved through asynchronous processing and background jobs. They can deliver responsive interfaces even during computationally demanding operations. Design Validation and Verification Product development involves numerous design iterations and validation steps to ensure the final product meets the desired performance and safety requirements. Knowledge-based engineering simplifies the design validation and verification processes by directly integrating computational tools and simulations into the design workflow. It can embed engineering rules and simulation models to automatically evaluate design alternatives. It also helps you perform virtual testing and assess the product’s behavior under various operating conditions. KBE systems enable engineers to define design constraints and requirements upfront. These constraints can include factors such as material properties, stress limits, and geometric tolerances. During the design process, the KBE system continuously checks the design against these constraints, providing real-time feedback to the engineers. Instant feedback helps identify design issues early in the development cycle, reducing the risk of costly errors and rework. KBE systems also use simulation models to forecast the product’s performance before building prototypes. The design procedures incorporate finite element analysis (FEA), computational fluid dynamics (CFD), and other simulation methods. Engineers can evaluate structural integrity, thermal behavior, and fluid flow characteristics. There’s less need for physical prototypes, and it saves time and money by doing virtual testing and analysis. Embrace Open Standards and Integration CAD software rarely operates in isolation. It often needs to interact with other software systems and exchange data with external tools. Embrace open standards and interoperability to integrate with commonly used file formats, industry-specific standards, and collaboration platforms. Support file import/export in common formats, including STEP, IGES, and STL, to ensure interoperability with various CAD systems and manufacturing procedures. Create APIs and SDKs that let outside developers add features to your CAD program or incorporate it into broader software ecosystems. Utilize existing libraries and frameworks for performing typical CAD tasks. You can also use it to collaborate with industry groups and communities to maintain current standards. Your CAD solution can benefit from integrating analysis tools, simulation software,

Read MoreMastering CAx Software Development: Tips and Best Practices for Efficient Design

Table of content Introduction What exactly is CAX software development? CAX Software: A Platform for Integration Tips and Best Practices for Efficient Design Conclusion Introduction The way engineers and designers build, evaluate, and visualize their products are completely transformed by computer-aided design (CAx) software. The complex realm of CAx software development plays a vital role in these potent CAx applications. This article will enable you to produce effective and reliable design tools by mastering CAx software development. These insights will help you build your skills and provide great CAx solutions. It’s perfectly suitable, irrespective of whether you are an experienced CAx software developer or just beginning your path. What exactly is CAx software development? The development of CAx software entails producing computer-aided design instruments used to construct, examine, and visualize items. It’s all about creating software programs that support streamlined design workflows, accurate 3D modeling, interactive visualization, and system integration. The below skills are needed in the development of CAx software: Creating effective CAx software equips users to increase productivity, rationally choose designs, and accelerate product development. . Tips and Best Practices for Efficient Design A thorough understanding of CAx software development is vital for your design skills to achieve maximum potential. By following key points, you can tap the true potential of CAx software development and improve your design abilities. Understand User Needs and Workflows Understand the needs and workflows of the end users thoroughly to produce efficient CAx software. Engage engineers, designers, and business experts to learn more about their difficulties, pain areas, and expectations. This understanding can help you create features and functionalities that meet customer needs, resulting in a more user-friendly and effective CAx system. Study common design workflows and identify areas where automation and optimization can provide significant value. Streamlining repetitive tasks, integrating intelligent design assistants, and incorporating simulation capabilities are some ways to enhance user productivity. Maintain Modularity and Scalability CAx software development often involves complex systems with numerous components and interdependencies. Adopt a modular architecture approach to ensure maintainability and scalability. Break down the software into independent modules or libraries, each responsible for specific functionalities. Better code organization, code reuse, and easier debugging and upkeep are all made possible by modularity. It also makes it possible for collaborative development, which quickens the entire development cycle by allowing numerous developers to work on various modules simultaneously. Additionally, it’s important to design the CAx software with scalability in mind. Anticipate future growth and changing requirements and build a flexible architecture to accommodate new features and adapt to evolving technology trends. This forward-thinking approach will prevent architectural bottlenecks and enable seamless expansion of the CAx software’s capabilities. Optimize Performance and Efficiency Efficient design tools must perform at their peak to handle intricate 3D models, big assemblies, and computationally demanding activities. The main goal of CAx software development should be performance optimization. Reduce computing complexity and memory utilization by using algorithms and data structures. Use approaches like spatial indexing, effective mesh representations, and level-of-detail algorithms to ensure quick rendering and easy interaction with the CAx models. Utilize the power of contemporary hardware by using multithreading and parallel processing. You can use several CPU cores and GPUs for quicker computations. The user experience can be further improved through asynchronous processing and background jobs. They can deliver responsive interfaces even during computationally demanding operations. Prioritize Visualization and Interactivity The capability of CAx software to offer interactive visualization and immersion is a vital feature. Users rely on precise and thorough representations of their concepts to make wise judgments. Therefore, create powerful rendering systems to manage accurate material, lighting, and shading attributes. Implement interactive controls and clear user interfaces that simplify a 3D model modification, annotation, and navigation. Include tools that let users examine your designs from different angles. Some options are dynamic zooming, panning, rotation, and sectioning. Additionally, it supports advanced visualization techniques, including transparency, reflections, and animations. All these provide a rich and engaging user experience. Real-time feedback during design modifications is crucial for efficient iterations and quick decision-making. Embrace Open Standards and Integration CAx software rarely operates in isolation. It often needs to interact with other software systems and exchange data with external tools. Embrace open standards and interoperability to integrate with commonly used file formats, industry-specific standards, and collaboration platforms. Support file import/export in common formats, including STEP, IGES, and STL, to ensure interoperability with various CAx systems and manufacturing procedures. Create APIs and SDKs that let outside developers add features to your CAx program or incorporate it into broader software ecosystems. Utilize existing libraries and frameworks for performing typical CAx tasks. You can also use it to collaborate with industry groups and communities to maintain current standards. Your CAx solution can benefit from integrating analysis tools, simulation software, and data management systems. Implement Robust Error Handling and Debugging As with any software development, CAx software can encounter errors and bugs during usage. Implementing robust error-handling mechanisms and effective debugging tools is essential to ensure a smooth user experience. Incorporate comprehensive error-handling routines that provide informative error messages and gracefully handle unexpected scenarios. Proper error reporting allows users to understand the issue and take appropriate actions to resolve it. Additionally, create debugging tools that help programmers locate and resolve software bugs. Logging methods, debuggers, and diagnostic tools help trace the execution flow, examine variables, and identify the main source of failures. You may improve the dependability and stability of your CAx software, which will boost user satisfaction. It also requires less support and maintenance work by prioritizing error handling and debugging. Conclusion Mastering CAx software development requires combining technical expertise, understanding user needs, and adherence to best practices. You can create efficient and powerful CAx tools that empower engineers and designers to bring their visions to life by: Strive for continuous learning, stay abreast of emerging technologies, and embrace innovation. Push the boundaries of CAx software development and shape the future of digital design. Ready to take your CAx software development skills to the next level?

Read MoreA Comprehensive Guide to Implementing a Product Configurator in Manufacturing

Table of content Introduction Benefits of Implementing a Product Configurator Understanding Product Configurators What is a Product Configurator? Types of Product Configurators Applications and Use Cases Planning for Product Configuration Selecting the Right Product Configurator Software Designing the Product Configuration Rules Defining Product Constraints and Dependencies Establishing Rule Hierarchy Creating a User-Friendly Configurator Interface Implementing and Integrating the Configurator Ensuring a Seamless Customer Experience Overcoming Challenges and Pitfalls Case Studies: Successful Product Configurator Implementations Conclusion Companies are continually looking for new, effective ways to deliver tailored products in the highly competitive manufacturing industry. A product configurator in manufacturing is a potent tool that enables these industries to visualize and design their preferred items. This extensive manual seeks to give producers a thorough grasp of product configurators and a step-by-step process for successfully adopting them. It also covers every step they need to fully realize the possibilities of a product configurator in production, from idea conceptualizing to choosing the appropriate software and ensuring seamless integration. Introduction Customers now want tailored items that cater to their interests, which has resulted in a paradigm shift in consumer demands for the manufacturing sector. Manufacturers are increasingly using product configurators to address this growing trend. An interactive and immersive experience is provided by a product configurator, which is a software that allows customers to design products based on specified options and rules. This manual intends to help manufacturers comprehend how to successfully deploy a product configurator in manufacturing. Benefits of Implementing a Product Configurator Manufacturers can gain a wide range of advantages by using a product configurator. These include improved client interaction, more effective operations, shorter lead times, fewer mistakes, more sales conversions, and more efficient production procedures. A properly implemented product configurator may set a business apart from its competitors and boost customer loyalty. Understanding Product Configurators Understanding the principles is crucial before moving on to implementation. You can reap the advantages of product configurators and promote business growth by obtaining a thorough understanding of them. What is a Product Configurator? A product configurator allows customers to personalize and visualize products according to their preferences. They select and combine various features, options, and components to create a customized product. The configurator validates the chosen options against predefined rules and constraints to ensure feasibility and generate accurate specifications. Types of Product Configurators Product configurators can be categorized into three main types: Applications and Use Cases Additionally, product configurators are used in business-to-business (B2B) scenarios to configure intricate industrial machinery and equipment conveniently. Planning for Product Configuration Proper planning sets the stage for a successful product configurator implementation. By investing time and effort in the planning phase, you can ensure a well-defined roadmap for implementing your product configurator. It helps you achieve your desired outcomes efficiently. Before implementing a product configurator, it is essential to define the scope and objectives of the project. This involves identifying the target market, understanding customer preferences, and determining the level of customization to be offered. Clear goals and a well-defined scope will guide the implementation process and ensure alignment with business objectives. The manufacturer must identify the customization choices available for a product’s design. This comprises adaptable features, elements, materials, colors, sizes, and other pertinent characteristics. You can choose the most desirable customization by carefully examining consumer needs, market trends, and rivals’ products. The complexity of the product plays a crucial role in designing an effective product configurator. Manufacturers must assess the complexity of the products and evaluate if they can configure them within the desired constraints. Complex products often require more sophisticated configurator solutions and meticulous rule definitions. A thorough understanding of data needs and system integration helps to implement a product configurator. Manufacturers should assess their current data infrastructure, which includes product details, costs, available stock, and manufacturing capacities. It’s vital to determine appropriate integration points with current enterprise systems. These include ERP (Enterprise Resource Planning) and CRM (Customer Relationship Management). Selecting the Right Product Configurator Software The correct software must be chosen in order for your product configurator installation to succeed. You can then support the goals of your business and provide a solid foundation for customization and efficiency. Let’s review some crucial elements: Manufacturers should take into account elements like the vendor’s experience, industry knowledge, track record, and customer feedback. Selecting a dependable, seasoned vendor with a solid, scalable solution is essential. Manufacturers should evaluate the features and functionality of different product configurator software solutions. Key features include a user-friendly interface, real-time visualization, 3D modeling, and dynamic pricing. They should also check for automated bill of materials generation, integration capabilities, and reporting and analytics tools. Software for product configuration should be scalable to enable future expansion. It should also be adaptable to changing consumer expectations. Additionally, it should be adaptable to shifting market trends, product configurations, and corporate procedures. It should also be able to manage big product catalogs and support many product lines. Seamless integration with existing enterprise systems is critical for efficient operations. The product configurator software should integrate smoothly with ERP, CRM, PLM (Product Lifecycle Management), and other relevant systems. It ensures accurate data synchronization, efficient order management, and streamlined production processes. Designing the Product Configuration Rules A successful product configurator’s foundation consists of effective configuration rules. Let’s examine several configurators and show how to set dependencies and rules. Offer accurate and practical setups and give clients a seamless customization experience by defining rule hierarchies and limitations. Rule-based configurators utilize predefined rules and logic to guide the configuration process. Manufacturers need to define these rules, which include compatibility constraints, dependencies among features, and valid combinations. Ensure the rules accurately represent the product’s configuration possibilities while preventing invalid or impractical combinations. Constraint-based configurators focus on defining constraints and dependencies among product features. These constraints can be in the form of logical rules, mathematical equations, or conditional statements. Always identify the dependencies and constraints between different features and establish validation mechanisms. It helps the configurator to generate feasible and valid configurations. Knowledge-based configurators leverage artificial

Read MoreBusiness Process Automation Success Stories: Streamlining Workflows with CAx

Table of content Introduction Understanding Business Process Automation Business Process Automation with CAD Streamlining Workflows with CAD: Success Stories Conclusion Introduction Industries across the board are continuously looking for ways to improve operational efficiency and productivity in today’s fast-paced corporate environment. Computer-Aided Design (CAD) is one potent tool that has changed numerous industries. CAD technology, which was first created to help with the creation, modification, and optimization of designs, has advanced to play a large part in business process automation. Businesses have effectively optimized their operations by using business process automation with CAD software, which has enhanced productivity, decreased costs, and raised customer satisfaction. This article explores several success stories of organizations that have harnessed the power of CAD to achieve business process automation and reap its benefits. Understanding Business Process Automation The term “business process automation” (BPA) describes how repetitive operations, activities, and workflows are streamlined and automated inside a company. It entails the use of software systems or tools that can carry out typical tasks with little assistance from humans, hence lowering error rates, boosting productivity, and conserving time and resources. Robotic process automation (RPA), workflow automation, and artificial intelligence (AI) are a few examples of technologies that are generally integrated into business process automation (BPA) in order to improve corporate operations, boost productivity, and free up employees’ time for higher-value tasks. Business Process Automation with CAD Streamlining workflows and improving business processes are two related concepts in the context of business process automation (BPA) and computer-aided design (CAD). Organizations are able to swiftly and accurately produce, alter, and visualize product designs because of the critical role that CAD software plays in automating design-related procedures and activities. Integrating CAD with BPA tools and systems offers numerous advantages for businesses. By automating the transfer of design data and streamlining manufacturing processes, organizations can enhance efficiency, facilitate collaboration, and minimize errors. This seamless connection enables smooth data interchange and communication, resulting in improved productivity across diverse industries such as manufacturing, automotive, architecture, and product development. Additionally, the integration of CAD and BPA tools reduces the time to market, allowing businesses to bring their products or designs to market faster and gain a competitive edge. Streamlining Workflows with CAD: Success Stories By examining real-world examples, we can gain insights into how CAD has revolutionized various sectors, enabling them to overcome challenges, enhance collaboration, and achieve impressive results. Let us explore some success stories and uncover the transformative impact of CAD that streamline workflow for automation. Automotive Industry The auto industry is fiercely competitive, as manufacturers compete to produce cutting-edge designs, shorten time to market, and improve manufacturing techniques. Automotive companies have benefited greatly from using CAD software to improve productivity and acquire a competitive edge. One notable success story is that of Tesla, the electric vehicle pioneer. Tesla extensively utilizes CAD software throughout its product development lifecycle. By digitizing their design processes, Tesla has achieved remarkable efficiencies in their engineering workflows. CAD enables the design team to quickly iterate and test various design concepts, leading to faster product development cycles. Additionally, CAD enables seamless collaboration between different teams, such as design, engineering, and manufacturing, ensuring efficient communication and reducing errors. As a result, Tesla has been able to introduce cutting-edge electric vehicles to the market faster than traditional automakers. Architecture and Construction The architecture and construction industry heavily relies on precise designs and efficient project management. CAD has significantly transformed this sector by automating various processes, from initial design creation to construction documentation. One remarkable success story is the Burj Khalifa in Dubai, the tallest building in the world. CAD played a crucial role in the construction of this architectural marvel. Through CAD software, the project’s architects and engineers were able to create detailed 3D models of the building, allowing them to visualize the structure and identify potential design flaws before construction began. This early detection of issues saved significant time and resources, ensuring a smoother construction process. Moreover, CAD facilitated effective collaboration among the project teams, architects, and contractors, enabling seamless communication and reducing costly rework. The successful completion of the Burj Khalifa is a testament to CAD’s power in automating and streamlining complex construction projects. Manufacturing and Industrial Processes For businesses looking to maximize productivity, decrease errors, and cut costs, efficient manufacturing and industrial processes are essential. CAD has transformed these industries by automating the design, prototype, and manufacturing processes. A notable success story comes from General Electric (GE), a global conglomerate in the manufacturing and industrial sectors. GE employs CAD software extensively in its turbine manufacturing division. By utilizing CAD, GE has been able to automate the design and optimize the role of turbine components. CAD enables engineers to create 3D models of turbine parts, simulate their performance under different conditions, and iterate designs to achieve optimal efficiency. This automation significantly reduces design and testing time, allowing GE to bring new turbine models to market faster. Additionally, the seamless transfer of design data to the production floor is made possible by CAD integration with computer-aided manufacturing (CAM) software. This results in an accurate manufacturing process and lowers errors. The use of CAD for business process automation by GE has increased productivity while also enhancing the functionality and dependability of their turbine products. Product Development and Prototyping CAD has been a game-changer for organizations engaged in product development and prototyping. It enables businesses to rapidly create, modify, and visualize product designs, accelerating time-to-market and reducing costs associated with physical prototyping. One notable success story is that of Dyson, a leading innovator in the home appliance industry. Dyson heavily relies on CAD software to design and develop their innovative products, such as vacuum cleaners and hair dryers. CAD enables Dyson’s engineers to quickly create virtual prototypes, simulate their functionality, and make necessary design iterations. This agile design process saves significant time and resources compared to traditional prototyping methods. Moreover, CAD facilitates seamless collaboration between design and engineering teams, enabling efficient communication and reducing errors during the product development phase.

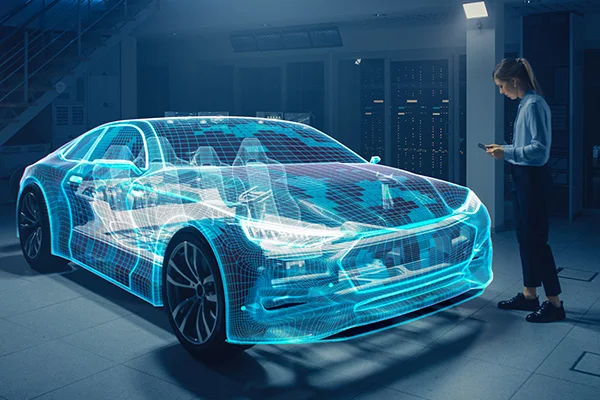

Read MoreCAD Software Development for Automotive Simulation: Accelerating Design Validation

Table of Content Introduction The Role of CAD Software in Automotive Simulation Challenges and Future Trends The Role of CAD Software in Sustainable Automotive Design Conclusion Introduction The automobile sector has always been on the cutting edge of technical development, continually pushing the envelope of innovation. Design validation ensures that new vehicle designs adhere to safety, performance, and legal criteria and is essential to automotive development. Computer-aided design (CAD) software, integrated with KBE principles, has revolutionized automobile simulation, significantly expediting the process and enhancing accuracy. Knowledge-based engineering incorporates design rules, engineering knowledge, and optimization algorithms into CAD software, empowering engineers to automate and streamline the design validation process. In this post, we’ll look at the importance of CAD software development in the automobile sector and how it affects design validation. The Role of CAD Software in Automotive Simulation Computer-aided design (CAD) software enables automotive engineers and designers to create, modify, and analyze vehicle components and systems in a virtual environment. By utilizing CAD software, automotive manufacturers can simulate various scenarios and evaluate the performance and behavior of different design options before physically building prototypes. This virtual prototyping process significantly accelerates design validation by identifying potential issues early in the development cycle. Let’s explore the key points highlighting how CAD software expedites the design validation process, enhances accuracy, promotes collaboration, and ultimately drives efficiency in automotive design and development. Let’s dive in and discover the power of CAD software in accelerating design validation. CAD software offers advanced visualization capabilities, allowing designers to create highly realistic 3D models of vehicles and their components. This level of visual fidelity enables engineers to examine the design from multiple angles and identify potential clashes, interferences, or design flaws. By detecting these issues early, the development team can make necessary adjustments swiftly, saving time and resources. CAD software offers potent simulation tools that allow testing and analyzing car designs virtually. Crash tests, aerodynamic performance, structural integrity, and thermal analysis are real-world situations that engineers can model. These simulations enable design modifications to improve safety, efficiency, and overall performance by demonstrating how the vehicle might behave in various conditions. By leveraging CAD software, designers gain the ability to make design modifications and evaluate their impact on the final product. This approach significantly reduces the time required compared to manual prototyping methods. The design validation process is greatly accelerated with the ability to test multiple iterations, assess their viability, and implement necessary improvements. The iterative nature of CAD empowers designers to expedite the development cycle and enhance the overall efficiency of product design and validation. CAD software enables seamless collaboration and communication among various stakeholders in the design validation process. Designers, engineers, and manufacturers can work together on a virtual platform, sharing design files, annotating, and providing real-time feedback. This collaborative environment improves efficiency, reduces miscommunication, and ensures everyone is on the same page, further expediting the design validation process. CAD software development for automotive simulation is crucial in reducing development costs. By identifying design flaws and issues early in the virtual prototyping stage, manufacturers can avoid expensive physical prototypes and costly rework. CAD software enables engineers to optimize designs for manufacturability, assembly, and materials, leading to cost savings during production. Challenges and Future Trends A thorough understanding of CAD software development is vital for your design skills to achieve maximum potential. By following key points, you can tap the true potential of CAD software development and improve your design abilities. CAD software must advance to handle the delicate relationships between many components as vehicle systems become more complex. A fluid workflow and accurate design validation depend on integration with other software tools, such as computer-aided engineering (CAE) and computer-aided manufacturing (CAM). The automotive industry is moving towards real-time simulation, where virtual testing can be performed accurately and quickly. CAD software developers must enhance simulation capabilities to provide real-time feedback during the design process, enabling faster iterations and better decision-making. VR and AR technologies VR and AR technologies can revolutionize the design validation process. By immersing designers and engineers in virtual environments, CAD software can provide an enhanced understanding of the design and its performance. Incorporating VR and AR capabilities into CAD software will offer a more intuitive and immersive experience, leading to better design decisions. Automation of some steps in the design validation process is possible with the help of AI and ML algorithms. AI-driven algorithms, for instance, may examine a lot of simulation data to find patterns, refine designs, and provide suggestions for enhancements. It’s possible to hasten the design validation process and increase overall efficiency by integrating AI and ML capabilities into CAD software. Effective data management and security have become crucial with the increasing reliance on digital design data and collaboration. CAD software development must address challenges related to data organization, version control, and secure data sharing among different stakeholders. Implementing robust data management systems and ensuring data security protocols will be paramount to protect valuable intellectual property and maintain confidentiality. The Role of CAD Software in Sustainable Automotive Design With an increasing focus on sustainability in the automotive industry, CAD software enables sustainable design practices. By facilitating virtual prototyping and simulation, CAD software reduces the need for physical prototypes, thus minimizing material waste and carbon footprint. The accurate analysis provided by CAD software helps optimize designs for energy efficiency, lightweight, and eco-friendly materials. Additionally, CAD software promotes team collaboration and communication, enabling seamless integration of sustainability considerations throughout the design validation process. Through its capabilities, CAD software empowers automotive manufacturers to embrace sustainable practices and develop environmentally conscious vehicles for a greener future. Conclusion The emergence of automotive simulation CAD software integrated with Knowledge-Based Engineering (KBE) is pivotal in accelerating design validation processes. This advanced CAD software equips automotive engineers and designers with a wide range of tools and functionalities to expedite development timelines and reduce costs. It empowers them to streamline design validation, improve efficiency, and deliver high-quality automotive solutions in a cost-effective and time-efficient manner. As technology continues to advance, KBE-driven CAD software addresses challenges. It embraces future trends like real-time

Read MoreEvaluating ROI: Measuring the Impact of Additive Manufacturing Implementation

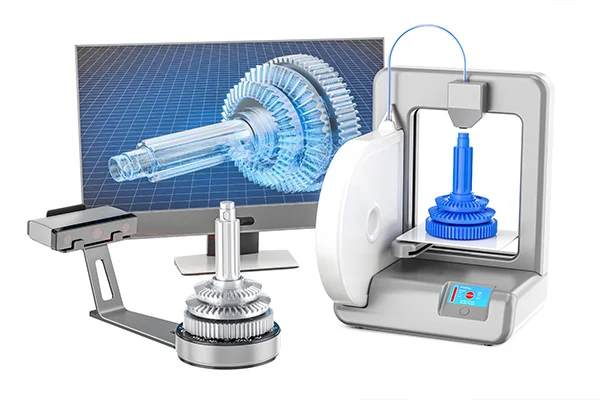

Table of content Introduction Understanding Additive Manufacturing Challenges and Considerations in Additive Manufacturing Implementation Future Trends and the Evolving Landscape of Additive Manufacturing ROI Conclusion Introduction The ability to produce complicated parts with remarkable speed and efficiency thanks to additive manufacturing, often known as 3D printing, has completely changed the industrial sector. Businesses are becoming more concerned with assessing the return on investment (ROI) related to using additive manufacturing solutions as the technology develops and becomes more widely used. This article looks at several aspects of additive manufacturing implementation and how organizations may evaluate their ROI effectively. Understanding Additive Manufacturing Additive manufacturing is a process that builds three-dimensional objects by adding successive layers of material based on a digital model. This technology offers numerous advantages over traditional manufacturing methods, including reduced lead times, lower costs, design flexibility, and the ability to produce complex geometries. These benefits have attracted a wide range of industries, including aerospace, automotive, healthcare, and consumer products, to incorporate additive manufacturing into their operations. Measuring ROI in Additive Manufacturing Assessing the costs, advantages, and dangers of implementing additive manufacturing is necessary to calculate the return on investment. When assessing the effects of additive manufacturing on your company, keep the following points in mind: Cost Analysis Begin by analyzing the costs associated with implementing additive manufacturing. This includes the cost of acquiring 3D printers, software, materials, and training. Additionally, consider the costs of maintaining and operating the equipment, as well as any required facility modifications. You can estimate the financial impact by comparing these costs with the potential savings due to additive manufacturing. Operational Efficiency Additive manufacturing can considerably increase operational efficiency because lead times are shortened and supply chains are made simpler. Analyze the potential for time and money savings in your production processes by using additive manufacturing. One method to save assembly stages and material waste is to combine several pieces into a single 3D-printed component. Design Optimization Another key advantage of additive manufacturing is design flexibility. Traditional manufacturing methods often have limitations on complex geometries, but additive manufacturing allows for intricate designs with minimal constraints. Assess how this design freedom can enhance product performance, reduce material usage, and enable innovation. Consider the potential cost savings and revenue generation resulting from optimized designs. Customization and Personalization Additive manufacturing enables customization and personalization at scale. Evaluate the market demand for customized products and assess how additive manufacturing can help meet these requirements. Customized products often command higher prices, leading to increased revenue potential. Supply Chain Optimization Due to its ability to support decentralized production and on-demand manufacturing, additive manufacturing has the potential to upend conventional supply chains. Consider the effects of localized manufacturing, lower transportation costs, and advantages of inventory management. Take into account the potential reduction in lead times and the capacity to react swiftly to demand fluctuations. Risk Management Like any investment, additive manufacturing comes with inherent risks. Evaluate the potential risks associated with implementing the technology, such as operational challenges, quality control, intellectual property concerns, and regulatory compliance. Mitigate these risks by developing robust strategies and considering them in your ROI calculations. Quantitative and Qualitative Factors Take into account both quantitative and qualitative considerations when assessing the ROI of additive manufacturing. Cost reductions, income growth, increased productivity, and less waste are examples of quantitative metrics. Improved consumer happiness, increased market competition, and the capacity to develop novel products are examples of qualitative metrics. Market Expansion and New Business Opportunities Additive manufacturing opens up new business opportunities and market expansion possibilities. Evaluate how implementing this technology can allow you to enter new markets, cater to niche customer segments, or offer unique products and services. Consider the potential revenue growth from tapping into previously unexplored markets or creating innovative business models based on additive manufacturing capabilities. Challenges and Considerations in Additive Manufacturing Implementation There are certain difficulties and things to think about in additive manufacturing implementation. Despite the fact that the technology has many advantages, businesses should be aware of any obstacles that could reduce the overall return on investment. Consider the following major difficulties: Initial Investment The initial investment required for additive manufacturing implementation can be substantial. Organizations need to assess their financial capabilities and determine if they have the necessary budget to acquire the equipment, software, and training required for successful implementation. Conduct a thorough cost analysis and consider alternative financing options if needed. Material Selection and Quality Control Additive manufacturing relies on various materials, each with its own unique properties. Organizations must carefully evaluate material options to ensure they are suitable for the intended applications. Maintaining consistent quality control throughout the additive manufacturing process is crucial to avoid defects or deviations in the final products. Intellectual Property and Data Security Additive manufacturing involves the use of digital models and designs, which can be susceptible to intellectual property theft or unauthorized replication. Organizations must implement robust security measures to protect their intellectual property and ensure data integrity throughout the additive manufacturing workflow. Future Trends and the Evolving Landscape of Additive Manufacturing ROI As additive manufacturing continues to evolve, several future trends will shape the ROI landscape. Understanding these trends can help organizations assess the long-term impact of additive manufacturing implementation. Here are some noteworthy trends: Conclusion As additive manufacturing continues to reshape the manufacturing landscape, evaluating the ROI of additive manufacturing implementation is crucial for organizations considering adopting this technology. It involves considering the challenges and considerations, examining real-world case studies, and understanding future trends in the additive manufacturing landscape. By carefully assessing the costs, benefits, and risks associated with additive manufacturing implementation, organizations can make informed decisions that maximize the ROI and leverage the full potential of this transformative technology. With ongoing advancements and increasing adoption, additive manufacturing will continue to reshape industries, drive innovation, and deliver substantial returns for forward-thinking organizations. Interested in transforming your manufacturing processes? Discover the impact of additive manufacturing implementation on your business. Evaluate ROI, explore case studies, and stay ahead of the evolving landscape. Embrace the

Read MoreOptimising Additive Manufacturing: Unleashing the Power of Slicing Algorithms

Table of Content Introduction Slicing algorithms: An understanding Types of Slicing Algorithms Optimisation Techniques Conclusion Introduction The industrial sector has transformed because of additive manufacturing, often known as 3D printing, which makes it possible to produce intricate geometries more effectively and affordably. The slicing algorithm is an essential part of the additive manufacturing process. Slicing algorithms help the printer deposit materials layer by layer by decomposing a 3D model into a sequence of 2D levels. The significance, varieties, and effects of additive manufacturing slicing algorithms on the calibre, speed, and accuracy of the manufacturing process will all be explored in this article. We will also review the optimisation methods used to improve slicing algorithm performance for better additive manufacturing results Slicing algorithms: An understanding At its core, additive manufacturing involves the layer-by-layer construction of a physical object based on a digital model. The slicing algorithm serves as the bridge between the digital model and the material creation. It takes the 3D model and slices it into a series of 2D layers, then translates it into machine instructions for the 3D printer. Each layer is a horizontal cross-section of the object that the printer will fabricate. Layer thickness, infill density, support structures, and printing path are just a few of the crucial factors slicing algorithms consider. While the infill density specifies how much material is utilised to fill the interior of the item, the layer thickness controls the print’s vertical resolution. Support structures are created to stabilise overhanging elements during printing, and the printing path defines the order in which the printer deposits material. Types of Slicing Algorithms In additive manufacturing, a variety of slicing algorithms are used. Each method has advantages and disadvantages, and the choice of one depends on the particular specifications of the printed product. Several popular slicing algorithms are listed below: Uniform Slicing Collect knowledge from subject matter experts, books, journals, and other sources, then organise it so a computer can process it. Adaptive Slicing This algorithm dynamically adjusts the layer thickness based on the object’s geometry. When there are smooth slopes, the layer thickness increases; when there are sharp features, the thickness decreases. Adaptive slicing improves The staircase effect, and the surface quality is lessened. Tree-like Slicing The printing path is optimised via tree-like slicing methods. These algorithms construct a hierarchical structure as opposed to strictly adhering to a layer-by-layer method, enabling the printer to optimise its movements and reduce travel times. As a result, printing takes less time and is more effective overall. Non-Manifold Slicing Non-manifold slicing algorithms can effectively handle complex geometries featuring overlapping surfaces and non-manifold edges, which is crucial for ensuring successful 3D printing. These algorithms play a vital role in detecting and rectifying any inconsistencies in the 3D model, guaranteeing optimal printing results. By addressing intricate geometries and resolving issues, non-manifold slicing algorithms enable the seamless translation of digital models into accurate physical representations. Optimisation Techniques The potential of additive manufacturing slicing algorithms has been optimised using various techniques established by researchers and engineers. These methods are intended to improve the manufacturing process’s precision, speed, and quality. Here are a few noteworthy optimisation techniques: Adaptive Layer Thickness As was already said, adaptive slicing modifies layer thickness dependent on the object’s geometry. This feature enables the printing process to produce higher resolution in regions requiring finer details and faster printing speeds in parts with less intricate elements. Infill Optimisation The inside framework of the printed object is referred to as infill. Optimising the infill pattern and density can considerably affect the item’s strength, weight, and material utilisation. Advanced slicing algorithms enable the custom design of infill patterns like honeycomb, grid, or gyroid, each offering a different trade-off between strength and material usage. Support Structure Generation Support structures are frequently needed during printing to prevent the collapse or deformation of overhanging elements or complex shapes. Slicing optimised algorithms can intelligently create support structures only when required, minimising material waste and post-processing work. Printing Path Optimisation Printing speed and overall print quality can be impacted by the order in which the printer puts the materials. Optimisation approaches aim to reduce retraction movements, travel distances, and the printing route to eliminate pointless pauses and starts. The printing time can be decreased through printing path optimisation, increasing productivity and efficiency. Intelligent Cooling Strategies In additive manufacturing, cooling is essential, especially for materials prone to warping or distortion. By altering the printing speed, fan speed, and layer dwell time, slicing algorithms can incorporate adaptive cooling strategies to maximise cooling between layers. This raises dimensional accuracy while reducing thermal stress. Multi-Material Printing Multi-material prints are possible with several additive manufacturing techniques. The exact control of material deposition and transition points made possible by optimised slicing algorithms ensures smooth integration of various materials and minimises flaws or weak interfaces. Post-Processing Considerations To make removal easier or reduce the need for post-processing, slicing algorithms can also optimise the design of support structures. In the final stages of additive manufacturing, this saves time and effort. Conclusion The core of 3D printing is additive manufacturing slicing algorithms, which make it possible to turn digital models into actual products. The choice and optimisation of slicing algorithms substantially impact the quality, speed, and accuracy of additive manufacturing. Engineers and researchers can maximise the potential of additive manufacturing and open new doors in design and manufacturing by using adaptive layer thickness, infill optimisation, support structure generation, printing path optimisation, intelligent cooling strategies, multi-material printing, and post-processing considerations. The advancement of more sophisticated slicing algorithms and optimisation methods will result in additional advancements in print quality, effectiveness, and material utilisation as additive manufacturing progresses. Manufacturers can fully utilise the capabilities of additive manufacturing and promote innovation across various industries by being on the cutting edge of these developments. Ready to optimise your additive manufacturing process? Discover the power of Prescient’s advanced slicing algorithms and optimisation techniques. Contact us today to unlock the full potential of 3D printing and revolutionise your manufacturing capabilities.

Read MoreThe Future of CAD: Trends and Innovations in Product Development

Table of Content Introduction What exactly is Computer-Aided Design? Trends and Innovations in Product Development Conclusion Introduction Cutting-edge trends and breakthrough technology are driving the future of CAD, which is poised to revolutionize product development. CAD systems are getting more sophisticated and intuitive as artificial intelligence and machine learning become more prevalent, allowing designers to easily produce complicated designs. Virtual and augmented reality is changing how products are visualized and verified, allowing for immersive and interactive design experiences. The vision-based inspection system is one remarkable breakthrough in this developing landscape, utilizing the power of computer vision to automate quality control procedures, ensuring precise and error-free manufacturing. The future of CAD is one of boundless possibilities, ushering in a new era of product development. In this article, we will examine what computer-aided design (CAD) is, the new trends and breakthroughs influencing CAD’s future and how they affect the creation of new products. What exactly is Computer-Aided Design? Computer-Aided Design (CAD) is a game-changing technology that allows designers and engineers to realise their creative concepts. It is a digital design technique that substitutes old manual drawing methods to create precise, accurate, and efficient 2D and 3D models. CAD software offers a strong collection of tools that allow designers to easily see, analyse, and alter their designs. Complex geometries can be easily changed, prototypes can be simulated and tested, and designs may be optimized for manufacturing using CAD. CAD transforms the design workflow, increasing productivity, collaboration, and overall product quality. Trends and Innovations in Product Development Product creation is undergoing a transition as a result of technological breakthroughs in the quickly changing environment of today. The industry is undergoing groundbreaking breakthroughs transforming how we produce and optimize products, from cloud-based collaboration to AI-driven design. Let’s explore the latest trends and innovations revolutionizing the industry. Cloud-Based CAD The move to cloud-based solutions is one of the most important developments in CAD. Comparing cloud-based CAD platforms to traditional desktop software reveals several benefits. They enable real-time collaboration, so several team members can simultaneously work on the same project. Generative Design Generative design is a cutting-edge methodology that uses artificial intelligence (AI) algorithms to provide a variety of design possibilities based on a predetermined set of criteria. The software may explore various alternatives and produce optimised solutions by providing design goals and limitations. With the help of this technology, designers can investigate unusual concepts and find creative solutions that could not have been considered otherwise. The development of new products can move more quickly thanks to generative design, which can also cut down on material waste and improve performance. Integration with Virtual Reality (VR) and Augmented Reality (AR) Technologies for virtual reality (VR) and augmented reality (AR) have become very popular in recent years. By enabling designers and engineers to engage with virtual models more naturally and realistically, these immersive technologies add new dimensions to CAD. Insights into ergonomics, spatial relationships, and overall aesthetics can be gained by allowing users to visualise and experience a design in a simulated environment using virtual reality (VR). Contrarily, AR superimposes virtual models over the real world to enable real-time design changes and the ability to see how a product fits into its surroundings. The design review process might be revolutionized, cooperation could be improved, and decision-making could be enhanced by integrating CAD with VR and AR. Parametric and Feature-Based Modeling For many years, parametric modelling has been a mainstay of CAD software. It enables effective adjustments and updates by allowing designers to specify relationships between various design elements. By incorporating several characteristics, feature-based modelling advances parametric modelling by capturing design intent. Rapid design iterations are possible by changing or suppressing these aspects. Further developments in parametric and feature-based modelling will be made in CAD, making it simpler for designers to construct complicated designs and modify them in response to shifting requirements. Additive Manufacturing (3D Printing) The field of additive manufacturing, also called 3D printing, has expanded rapidly in recent years. CAD plays a significant part in this process by supplying digital models that are transformed into actual products. More additive manufacturing technologies will be integrated with CAD in the future, allowing designers to optimise designs specifically for 3D printing. This includes lattice structures, lightweight constructions, and intricate geometries that were previously impossible or difficult to create using conventional techniques. Numerous industries, including aerospace, healthcare, and automotive, will continue to transform due to the convergence of CAD and additive manufacturing. Artificial Intelligence and Machine Learning Various industries, including CAD, are experiencing radical change due to artificial intelligence (AI) and machine learning (ML). Large-scale design data analysis, pattern recognition, and recommendation generation are all capabilities of AI algorithms. This can help designers make wise judgements and enhance the entire design process. Predictive models for design optimization, cost estimate, and performance analysis can also be created using machine learning algorithms trained on already-existing design data. By integrating AI and ML into CAD software, designers can take advantage of data-driven insights, automate tedious activities, and improve creativity. Internet of Things (IoT) Integration A network of networked devices that gather and share data is known as the Internet of Things (IoT). CAD software will progressively interface with IoT platforms as IoT technology develops. Thanks to this connection, designers will be able to construct linked, smart items. Engineers may collect real-time data on product performance, usage trends, and maintenance requirements by embedding sensors and connectivity into their designs. Then, with the help of this information, future designs, user experiences, and preventive maintenance may all be enhanced. Conclusion The development of products could be drastically altered thanks to CAD. CAD will become more potent, available, and user-friendly as technology advances, enabling designers and engineers to produce cutting-edge, environmentally responsible goods in a market that is getting more competitive. For organizations looking to maintain their position at the forefront of product development in the years to come, embracing these trends and utilizing CAD skills will be essential. Experience the future of CAD with Prescient: Unlock innovative

Read More