Exploring the Benefits of IIoT for Manufacturing Efficiency and Productivity

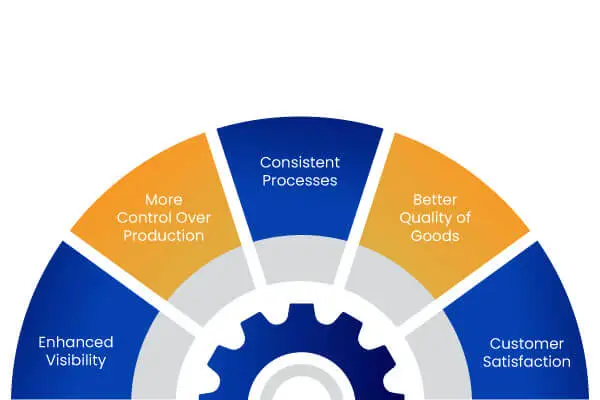

Table of content Understanding the Industrial Internet of Things (IIoT) Benefits of IIoT for Manufacturing Conclusion Does IIoT shape the future of manufacturing efficiency and productivity? In the dynamic realm of manufacturing, where innovation constantly redefines traditional processes, a key player has emerged on the technological stage: the Industrial Internet of Things (IIoT). As manufacturing industries seek novel avenues to optimize their operations, IIoT stands out as a game-changer, promising a host of benefits that hold the potential to revolutionize the way products are created. This article delves into the manifold advantages of IIoT to the manufacturing sector, illuminating its capacity to elevate efficiency and productivity to unprecedented heights. Understanding the Industrial Internet of Things (IIoT) The term Industrial Internet of Things (IIoT) describes how industrial equipment, such as sensors, machinery, and other assets, are connected to the Internet to communicate and gather data. The Industrial Internet of Things (IIoT) is geared towards industrial settings. It emphasizes the integration of smart technology in production processes, in contrast to the consumer-oriented Internet of Things (IoT), which focuses on linking common goods. Benefits of IIoT for Manufacturing The Industrial Internet of Things (IIoT) has emerged as a game-changing technology in the manufacturing sector, offering many benefits that enhance efficiency and boost productivity. Here are some key advantages of implementing IIoT in manufacturing: ● Real-Time Monitoring and Data Analytics One of the primary advantages of IIoT in manufacturing is real-time monitoring and data analytics. Traditional manufacturing processes often rely on periodic manual checks and routine maintenance. However, IIoT-enabled sensors and devices continuously gather data on various aspects of the production line, such as machine performance, temperature, humidity, and energy consumption. This real-time data empowers manufacturers with actionable insights that facilitate quick decision-making. By identifying bottlenecks, predicting machine failures, and optimizing production schedules, IIoT enables manufacturers to operate with greater efficiency. For instance, if a machine’s temperature rises above a safe threshold, IIoT sensors can trigger an alert, allowing maintenance personnel to address the issue before it escalates into a costly breakdown. ● Predictive Maintenance IIoT’s impact on manufacturing efficiency is particularly evident in the realm of predictive maintenance. Traditional maintenance practices are often based on predetermined schedules, leading to either unnecessary maintenance expenses or unexpected downtime due to equipment failure. IIoT transforms this approach by enabling predictive maintenance through continuously monitoring equipment conditions. By analyzing data patterns and performance trends, IIoT systems can predict when a machine is likely to fail. This empowers manufacturers to schedule maintenance activities precisely when needed, minimizing downtime and maximizing the lifespan of the equipment. As a result, production processes become more reliable, efficient, and cost-effective. ● Enhanced Supply Chain Management Efficient supply chain management is crucial for maintaining steady manufacturing operations. IIoT contributes to optimizing the supply chain with the help of real-time visibility into the movement of goods, materials, and components. Smart sensors and tracking devices embedded in products and packaging allow manufacturers to track shipments’ location, condition, and status throughout the entire supply chain. This degree of openness facilitates efficient inventory management, minimizes delays, and avoids stockouts. To maintain optimal inventory levels, manufacturers can quickly adapt production schedules to fluctuations in demand. As a result, IIoT-enabled supply chain management increases operational efficiency and improves customer satisfaction while reducing waste. ● Process Automation and Efficiency IIoT facilitates process automation by enabling seamless communication and collaboration between machines, systems, and human operators. Intelligent devices equipped with sensors can gather data from various stages of the production process, making it possible to automate tasks that were previously manual and time-consuming. For example, in a manufacturing line producing automotive components, IIoT-connected robots can automatically adjust their movements and actions based on real-time data inputs. This not only ensures consistent quality but also accelerates the production process by eliminating the need for manual intervention. The result is higher throughput, reduced error rates, and increased overall efficiency. ● Data-Driven Decision Making Informed decision-making is at the heart of effective manufacturing management. IIoT amplifies the decision-making process by providing access to a wealth of data-driven insights. With real-time information on machine performance, production rates, and quality metrics, managers can make more accurate and timely decisions. IIoT data analytics can reveal patterns and correlations that might not be apparent through traditional methods. This enables manufacturers to identify opportunities for process optimization, cost reduction, and quality enhancement. By leveraging these insights, manufacturing managers can fine-tune their strategies, improving operational performance and increasing competitiveness. ● Quality Control and Defect Prevention Maintaining product quality is a top priority for manufacturers, and IIoT plays a pivotal role in ensuring consistent quality control. Smart sensors embedded in production equipment can detect even the slightest deviations from desired specifications. This real-time monitoring allows manufacturers to identify defects early in the production process, preventing the creation of faulty products. Moreover, IIoT facilitates root cause analysis by capturing detailed data on production parameters. When a quality issue arises, manufacturers can trace back through the data to identify the exact point of failure and implement corrective measures. This not only reduces scrap and rework but also establishes a culture of continuous improvement. ● Customization and Flexibility The modern market demands products that are tailored to specific customer needs, which requires manufacturing processes to be flexible and adaptable. IIoT technology contributes to this flexibility by enabling rapid reconfiguration of production lines and processes. Manufacturers can use IIoT to monitor real-time demand patterns and adjust production schedules accordingly. This allows for efficient batch production and on-the-fly customization, minimizing lead times and reducing excess inventory. Whether adjusting product specifications or changing production volumes, IIoT empowers manufacturers to stay responsive to market demands. ● Workforce Empowerment IIoT not only transforms machinery but also empowers the workforce. With access to real-time data and insights, operators and technicians can make informed decisions and take proactive actions. IIoT systems can provide operators with alerts, notifications, and guidance, helping them optimize machine settings and respond to anomalies promptly. Moreover, IIoT offers training and skill development opportunities. As technology becomes more integrated into manufacturing processes, workers can learn to operate and troubleshoot sophisticated IIoT-enabled equipment. This not only enhances their skill set but also contributes to a

Read MoreOptimization Strategies in Knowledge-Based Engineering for Manufacturing Processes

Table of content The Evolution of Knowledge-Based Engineering The Importance of Optimization in Manufacturing Optimization Strategies in Knowledge-Based Engineering 1. Design Exploration and Parametric Optimization2. Generative Design3. Process Optimization4. Multi-Objective Optimization5. Knowledge-Based Decision Support Applications of Optimization in Knowledge-Based Engineering 1. Aerospace Industry2. Automotive Manufacturing3. Pharmaceutical Manufacturing4. Sustainable Manufacturing5. Consumer Electronics Future Trends and Challenges Conclusion Manufacturing processes have undergone significant transformations in recent years, emphasizing efficiency, precision, and cost-effectiveness. Knowledge-Based Engineering (KBE) has emerged as a crucial framework that combines engineering knowledge with computational tools to streamline the design and manufacturing processes. This article will explore the optimization strategies employed in Knowledge-Based Engineering for manufacturing processes, highlighting their importance, applications, and future potential. The Evolution of Knowledge-Based Engineering Before delving into optimization strategies, it’s essential to understand the evolution of Knowledge-Based Engineering and its role in manufacturing. KBE is a discipline that integrates knowledge from various domains, including engineering, materials science, and manufacturing, into a digital framework. This framework allows engineers and designers to leverage existing knowledge and expertise to expedite product development and enhance manufacturing processes. The roots of KBE can be traced back to Artificial Intelligence (AI) and Expert Systems, which aimed to replicate human expertise in solving complex problems. Over time, KBE has evolved to incorporate advanced techniques such as machine learning, knowledge representation, and optimization algorithms. This evolution has paved the way for KBE to play a pivotal role in modern manufacturing. The Importance of Optimization in Manufacturing Optimization lies at the heart of efficient and cost-effective manufacturing processes. It involves finding the best combination of parameters or variables to achieve specific goals while minimizing costs or maximizing performance. In manufacturing, optimization can address various challenges, including: Read More: India’s Growing Video Surveillance Market Optimization Strategies in Knowledge-Based Engineering Knowledge-based engineering employs various optimization strategies to address the challenges mentioned above. These strategies harness the power of data, knowledge, and advanced algorithms to drive efficiency and innovation in manufacturing processes. Here are some key optimization strategies used in KBE: 1. Design Exploration and Parametric Optimization KBE systems enable engineers to explore a wide range of design alternatives quickly. By defining design parameters and constraints, engineers can use optimization algorithms to find the best design that meets predefined objectives. This approach not only accelerates the design process but also ensures that the final product is optimized for performance, cost, and manufacturability. 2. Generative Design Generative design is an advanced optimization technique that leverages AI and computational algorithms to generate innovative design solutions. Engineers input design goals and constraints, and the generative design software explores countless possibilities, often coming up with unconventional and highly efficient designs that human designers may not have considered. 3. Process Optimization Manufacturing processes often involve intricate workflows with multiple variables. KBE systems use optimization algorithms to fine-tune these processes by adjusting parameters such as temperature, pressure, and feed rates. This improves process efficiency, reduces energy consumption, and minimizes waste. 4. Multi-Objective Optimization In many manufacturing scenarios, multiple conflicting objectives must be considered simultaneously. Multi-objective optimization algorithms enable engineers to find solutions that balance these objectives. For example, manufacturers may want to minimize production costs while maximizing product quality and sustainability. KBE can help identify the best compromise among these objectives. 5. Knowledge-Based Decision Support KBE systems integrate expert knowledge and best practices into decision support tools. This knowledge can guide engineers and designers in making informed decisions throughout the product development and manufacturing processes. By providing access to a wealth of expertise, KBE enhances decision-making and leads to optimized outcomes. Applications of Optimization in Knowledge-Based Engineering The applications of optimization in Knowledge-Based Engineering for manufacturing processes are diverse and impactful. Let’s explore some real-world examples: 1. Aerospace Industry In the aerospace industry, where safety and performance are paramount, KBE systems are used to optimize aircraft design, engine performance, and manufacturing processes. Parametric optimization ensures that aircraft components are lightweight, fuel-efficient, and aerodynamically sound. 2. Automotive Manufacturing Automotive manufacturers employ KBE for vehicle design and production optimization. Generative design techniques help create lightweight yet structurally robust components, while process optimization minimizes assembly line bottlenecks and reduces production costs. 3. Pharmaceutical Manufacturing Pharmaceutical companies use KBE to optimize drug formulation processes, ensuring the consistent quality and efficacy of medications. Multi-objective optimization balances production costs, regulatory compliance, and product quality. 4. Sustainable Manufacturing Optimization plays a pivotal role in achieving sustainability goals. For example, in the paper and pulp industry, KBE is used to optimize resource allocation, reducing energy consumption and minimizing waste. Similarly, in renewable energy sectors, KBE aids in optimizing the design and operation of wind turbines and solar panels for maximum energy production. 5. Consumer Electronics The rapid pace of innovation in the consumer electronics industry demands efficient design and manufacturing processes. KBE tools are used to optimize the form and function of electronic devices while minimizing production costs. Also Read: What is Asset Tracking and What are its Benefits Future Trends and Challenges As technology continues to advance, the field of Knowledge-Based Engineering for manufacturing processes is expected to evolve further. Here are some future trends and challenges to watch for: Conclusion Knowledge-based engineering has ushered in a new era of optimization in manufacturing processes. By leveraging engineering knowledge, data, and advanced algorithms, KBE systems enable engineers and designers to create more efficient and sustainable products and processes. The future holds even more promise, with AI, digital twins, and sustainability playing pivotal roles in shaping the landscape of manufacturing optimization. As manufacturers continue to embrace KBE, the industry will undoubtedly see further improvements in efficiency, cost-effectiveness, and sustainability, driving innovation and progress in the world of manufacturing. If you’re ready to take your manufacturing processes to the next level with state-of-the-art Knowledge-Based Engineering solutions, consider exploring what Prescient offers. Their expertise in KBE can help you optimize your operations and stay ahead in the competitive manufacturing landscape. Don’t miss the opportunity to transform your manufacturing processes with Prescient’s cutting-edge solutions.

Read MoreA Comprehensive Guide to Energy Management Information Systems (EMIS)

Table of content Understanding EMIS Key Components of EMIS Benefits of EMIS Implementation Challenges in EMIS Implementation EMIS Implementation Best Practices EMIS and the Future Conclusion In today’s quickly changing world, energy management has emerged as a top priority for all parties, including people, corporations, and governments. Effective energy management solutions are more important than ever due to rising expenses, increased energy demand, and growing environmental concerns. Energy Management Information Systems (EMIS) are useful in this situation. This in-depth manual will delve into the world of EMIS, examining what they are, how they operate, what they offer, what issues they present, and how they contribute to a more sustainable future. Understanding EMIS Modern software systems called Energy Management Information Systems (EMIS) are created to track, manage, and optimize how much energy is used in industrial processes, buildings, and other facilities. Using EMIS, businesses may gather, examine, and act on real-time energy data to make decisions that will cut costs, increase efficiency, and have the least possible negative environmental effects. These systems offer a comprehensive picture of energy use across various industries, including data centers, transportation networks, manufacturing facilities, office buildings, and industrial facilities. Key Components of EMIS EMIS comprises several key components that work in tandem to provide a comprehensive solution for efficient energy management. These include: ● Data Collection and Monitoring EMIS gathers energy-related data from various sources, such as meters, sensors, and building automation systems. This data includes information on electricity, natural gas, water, temperature, occupancy, etc. Real-time monitoring ensures that organizations have an up-to-date view of energy usage patterns. ● Data Analysis and Reporting The collected data is processed and analyzed with advanced algorithms and machine-learning techniques. EMIS generates insightful reports, dashboards, and visualizations that provide stakeholders with actionable insights into energy consumption trends, anomalies, and potential areas for improvement. ● Energy Modeling and Simulation Some EMIS incorporate energy modeling and simulation capabilities. This allows organizations to simulate different scenarios and strategies to identify the best ways to optimize energy consumption while maintaining comfort and operational requirements. ● Alerts and Notifications EMIS can be configured to send alerts and notifications when energy consumption exceeds predefined thresholds or when anomalies are detected. This proactive approach enables prompt responses to deviations from expected energy usage patterns. ● Automated Control and Optimization Advanced EMIS can automate energy-saving measures by controlling systems such as HVAC (Heating, Ventilation, and Air Conditioning), lighting, and industrial processes. This ensures that energy-consuming systems operate efficiently and are adjusted in real-time depending on demand and external factors. ● Benchmarking and Comparison EMIS often allows organizations to compare their energy performance with industry standards or similar facilities. Benchmarking facilitates setting realistic energy reduction goals and tracking progress over time. Benefits of EMIS Implementation Adopting Energy Management Information Systems can yield a wide array of benefits for organizations, regardless of their size or sector. Some of these benefits include: 1. Cost Savings EMIS enables organizations to identify energy wastage and inefficiencies, reducing energy consumption and lowering utility bills. Organizations can allocate their budgets efficiently and invest in other critical areas by optimizing energy use. 2. Environmental Sustainability Reducing energy consumption directly contributes to a lower carbon footprint. EMIS empowers organizations to track their greenhouse gas emissions, align with sustainability goals, and contribute to a greener future. 3. Data-Driven Decision Making EMIS provides data-driven insights that support informed decision-making. Organizations can identify trends, patterns, and outliers in energy consumption, enabling them to make strategic choices to optimize operations. 4. Operational Efficiency Real-time monitoring and automated control functionalities offered by EMIS enhance operational efficiency. Systems like HVAC can be adjusted based on occupancy patterns and external conditions, ensuring optimal comfort while minimizing energy waste. 5. Regulatory Compliance EMIS aids organizations in complying with energy-related regulations and standards. By tracking and reporting energy consumption data, organizations can avoid penalties and maintain a good reputation with regulatory bodies. 6. Predictive Maintenance Some EMIS platforms can predict equipment failures and maintenance needs by analyzing energy consumption patterns. This proactive approach minimizes downtime and extends the lifespan of the equipment. Challenges in EMIS Implementation While the benefits of EMIS are significant, implementing and maintaining these systems can pose challenges. Some challenges that might pop up are: 1. Data Quality and Integration EMIS effectiveness hinges on accurate and reliable data. Integrating data from diverse sources, ensuring compatibility, and addressing data gaps can be complex and time-consuming. 2. Initial Investment The upfront costs of implementing EMIS, including hardware, software, and staff training, can be substantial. However, the long-term cost savings often outweigh the initial investment. 3. Change Management Introducing EMIS may require changes in organizational processes and employee behaviors. Overcoming resistance to change and ensuring proper training are crucial for successful implementation. 4. Data Security Data security is a paramount concern due to the increasing reliance on digital systems. Protecting sensitive energy consumption data from cyber threats is essential to maintain the integrity of EMIS. 5. Complexity EMIS can be intricate systems, particularly in large and diverse organizations. Ensuring the system is user-friendly, and the data is understandable is important for driving meaningful actions. EMIS Implementation Best Practices Successfully implementing an Energy Management Information System (EMIS) requires careful planning and execution. Here are some best practices to ensure a smooth and effective implementation: By following these practices, organizations can maximize the benefits of EMIS and drive sustainable energy management outcomes. EMIS and the Future As the world continues to grapple with energy challenges and environmental concerns, the role of EMIS becomes increasingly vital. These systems will play a crucial role in shaping a more sustainable future by enabling organizations and individuals to take control of their energy consumption. With advancements in technology, integrating IoT (Internet of Things), AI (Artificial Intelligence), and cloud computing will further enhance the capabilities of EMIS. Conclusion Energy Management Information Systems (EMIS) are pivotal tools for organizations seeking to manage their energy consumption effectively, reduce costs, and contribute to a greener world. EMIS empowers stakeholders to make informed decisions and optimize energy usage across various sectors by providing real-time data, analysis, and automation. While challenges in implementation exist, the long-term benefits, including cost savings, environmental sustainability,

Read MoreEmerging Trends in Digital Factories: Shaping the Future of Manufacturing

Table of content Understanding Digital Factories Emerging Trends in Digital Factories Emerging Trends in Digital Factories Conclusion Digital transformation is fueling unheard-of developments in the industrial setup’s quickly changing landscape, resulting in the rise of digital factories. These cutting-edge manufacturing facilities are at the forefront of innovation, utilizing state-of-the-art technology to streamline procedures, boost productivity, and reimagine manufacturing processes. Several major trends are influencing the future of manufacturing as we move deeper into the twenty-first century, and digital factories are at the center of this shift. Understanding Digital Factories At its core, a digital factory is a manufacturing facility that leverages advanced digital technologies to optimize and streamline every facet of the production process. It represents a convergence of physical manufacturing with digital capabilities, resulting in a seamless integration of data, machines, and processes. Unlike conventional manufacturing, where physical operations often dominate, digital factories place data-driven decision-making and automation at the forefront. Central to the concept of a digital factory is the idea of interconnectedness. This interconnectedness spans machines, sensors, devices, and even personnel, creating a networked ecosystem that enables real-time data sharing and collaboration. The data generated by these interconnected systems provides insights that drive operational improvements, enhance product quality, and facilitate predictive maintenance. Emerging Trends in Digital Factories Now that we have a solid understanding of what digital factories entail, let’s delve into the emerging trends shaping their trajectory and influencing the future of manufacturing. ● Smart Manufacturing and Industry 4.0 The fourth industrial revolution is leading in an era of smart manufacturing that relies on interconnected systems and real-time data analysis. Digital factories leverage technologies like the Internet of Things (IoT) and Artificial Intelligence (AI) to create highly interconnected ecosystems. These ecosystems enable machines, sensors, and devices to communicate and collaborate autonomously, leading to seamless production processes and real-time decision-making. Integrating Industry 4.0 principles in digital factories enables predictive maintenance, where machines can identify and address potential issues before they result in downtime. This predictive approach reduces operational disruptions and optimizes maintenance schedules, thereby improving overall productivity and resource utilization. ● Robotics and Automation Automation has been a cornerstone of manufacturing for decades, but digital factories are taking it to new heights with the integration of advanced robotics. Collaborative robots, or cobots, are becoming increasingly common in these settings. These robots can work alongside human operators, enhancing efficiency and precision in tasks ranging from assembly to quality control. Machine learning algorithms are also employed to teach robots complex tasks, enabling them to adapt to changing environments and requirements. This increases flexibility and reduces the need for reprogramming when tasks change, making manufacturing processes more agile. ● Digital Twins Digital twins are virtual copies of physical products, processes, or systems. These twins are created in digital factories to simulate and analyze various aspects of the production process. By generating a digital representation of a product or a production line, manufacturers can run simulations and scenarios to optimize efficiency, test different variables, and identify potential bottlenecks. Digital twins enable data-driven decision-making by providing insights into how changes in one aspect of the process might impact the entire production line. This technology minimizes risks, accelerates development cycles, and enhances overall product quality. ● Additive Manufacturing and 3D Printing Additive manufacturing, commonly known as 3D printing, revolutionizes how products are designed and produced. Digital factories capitalize on this technology to create intricate and customized components with reduced material waste. This approach simplifies the production process and allows for on-demand manufacturing, reducing the need for large inventories. Moreover, additive manufacturing enables the production of complex geometries that were earlier challenging or impossible to create using traditional manufacturing methods. This level of design freedom opens up new possibilities for innovation across industries. ● Data-Driven Decision Making The influx of data generated by interconnected systems in digital factories is a goldmine for informed decision-making. With advanced data analytics, manufacturers can gain insights into production trends, performance metrics, and customer preferences. This information helps optimize processes, identify areas for improvement, and tailor products to meet market demands more effectively. Machine learning and AI algorithms can detect patterns in large datasets that human analysts might miss. This predictive analysis can guide manufacturers in adapting to changing market conditions swiftly and proactively. ● Cybersecurity Challenges The interconnected nature of digital factories presents both opportunities and challenges. The primary challenge often encountered is cybersecurity. With the increase in interconnected devices and data exchange, the potential attack surface for malicious actors also expands. Securing sensitive production data, proprietary designs, and critical infrastructure becomes paramount. Manufacturers must implement robust cybersecurity measures to safeguard their digital factories against cyber threats. This includes encryption, multi-factor authentication, intrusion detection systems, and regular security audits. ● Sustainability and Green Manufacturing As the world grapples with environmental concerns, sustainability has become a central focus for industries, including manufacturing. Digital factories are contributing to sustainable practices through various means. One of the ways this is achieved is by optimizing processes to reduce waste and energy consumption. Data-driven insights enable manufacturers to identify inefficiencies and implement eco-friendly solutions. Additive manufacturing also plays a role in sustainability by minimizing material waste, and it has the potential to revolutionize supply chains with localized production. This helps reduce the carbon footprint in relation to the transportation and storage of goods. ● Global Supply Chain Transformation Digital factories are reshaping traditional global supply chains. By adopting localized manufacturing practices and leveraging technologies like additive manufacturing, companies can reduce their dependence on complex and lengthy supply chains. This shift allows for quicker response times to market demands, reduced lead times, and greater flexibility in addressing regional preferences. ● Skill Transformation and Workforce Development Integrating advanced technologies in digital factories necessitates a shift in workforce skills. As automation and AI become more prevalent, workers must acquire new skills to manage and maintain these technologies. Upskilling and reskilling programs are becoming essential to ensure that the workforce remains relevant and adaptable in the face of technological changes. ● Human-Machine Collaboration While automation and robotics are advancing, human workers remain integral to manufacturing processes. Digital

Read MoreCAx Software Development for Automotive Design: Enabling Innovation and Efficiency

Table of content Evolution of Automotive Design: From Analog to Digital Realms Enabling Innovation: Pushing Boundaries of Creativity Enhancing Efficiency: Streamlining Design and Development Shaping the Future of Mobility: CAx Software and Beyond Conclusion In the realm of automotive design, the convergence of technology and creativity has revolutionized how vehicles are conceptualized, designed, and manufactured. Central to this transformation is Computer-Aided Design (CAx) software, a vital tool that empowers designers and engineers to visualize, iterate, and refine their ideas in a virtual environment before translating them into tangible vehicles. In this article, we delve into the pivotal role of CAx software development in the automotive design sector, exploring how it drives innovation, enhances efficiency, and shapes the future of mobility. Evolution of Automotive Design: From Analog to Digital Realms Before the advent of CAx software, automotive design was a labor-intensive process reliant on manual sketches, clay models, and physical prototypes. The iterative nature of design required significant time and resources, leading to lengthy development cycles. However, the digital revolution changed the game entirely. CAx software emerged as a transformative tool, allowing designers to create intricate and precise 2D and 3D models on computers. The shift from traditional drafting boards to digital workstations marked a paradigm shift, as it facilitated rapid exploration of design concepts, easy modifications, and collaborative sharing of ideas across teams and geographical boundaries. This digital transformation was a key catalyst for the innovation and efficiency that now define the automotive design landscape. Enabling Innovation: Pushing Boundaries of Creativity CAx software development has propelled innovation in automotive design by providing designers with a canvas where imagination knows no limits. The software’s capabilities extend far beyond mere geometric representations – they enable the integration of engineering, ergonomics, aesthetics, and functionality into a single cohesive design. ● Concept Exploration CAx software empowers designers to explore a wide array of design alternatives quickly and efficiently. Through parametric modeling, designers can manipulate variables such as proportions, dimensions, and features in real-time, instantly visualizing the impact of each change. This flexibility encourages bold experimentation and innovation in vehicle design, as designers can push the boundaries of traditional aesthetics and challenge conventional notions. ● Advanced Visualization Modern CAx tools incorporate realistic rendering and simulation capabilities, allowing designers to visualize materials, lighting, and environmental interactions accurately. This empowers them to make informed decisions about the visual and tactile aspects of the vehicle, resulting in designs that are not just visually striking but also functional and aligned with user expectations. ● Integration of Cutting-Edge Technologies CAx software has evolved to integrate emerging technologies like Virtual Reality (VR) and Augmented Reality (AR). These technologies enable immersive experiences where designers can interact with their designs in virtual spaces. For instance, designers can “walk around” a virtual car, examining its proportions and features from all angles, leading to more comprehensive and insightful design evaluations. Enhancing Efficiency: Streamlining Design and Development Efficiency is at the heart of CAx software’s impact on automotive design. It accelerates the entire design and development lifecycle, from initial concept to final manufacturing, resulting in faster time-to-market and reduced costs. ● Parametric Design One of the key features of CAx software is parametric modeling, which links various design elements together with equations and constraints. This means that when one aspect of the design changes, other related elements adjust automatically. This significantly speeds up the design iteration process, allowing designers to explore numerous possibilities quickly. ● Digital Prototyping CAx software eliminates the need for physical prototypes in the early design stages. Digital prototyping involves creating virtual representations of the vehicle’s components and digitally testing their fit, function, and interaction. This approach reduces the need for costly physical iterations and accelerates the design validation process. ● Collaborative Workflows CAx software enables seamless collaboration between designers, engineers, and other stakeholders, regardless of geographical location. This fosters an environment where multidisciplinary teams can work together in real-time, share feedback, and collectively refine the design. Such collaboration reduces communication gaps and ensures that the final design aligns with both creative and technical requirements. ● Data-Driven Decision Making CAx software generates a wealth of data throughout the design process. Designers can analyze this data to make informed decisions about the design’s feasibility, performance, and manufacturability. This data-driven approach minimizes the risk of design flaws and optimizes the final product for real-world production. Shaping the Future of Mobility: CAx Software and Beyond The trajectory of CAx software development in automotive design continues to evolve, guided by the dynamic landscape of mobility and technology trends. The future promises even more innovation and efficiency, driven by several key areas of development. ● Generative Design This emerging trend leverages Artificial Intelligence (AI) algorithms to explore and generate design options based on specified criteria. The generative design pushes the boundaries of what human designers can conceive by presenting novel design solutions that optimize parameters such as weight, strength, and aerodynamics. This approach will likely revolutionize automotive design by uncovering new possibilities that were previously unexplored. ● Additive Manufacturing Integration As additive manufacturing (3D printing) gains traction in the automotive industry, CAx software will be pivotal in optimizing designs for this manufacturing method. Complex geometries that were once challenging to produce using traditional methods can now be easily manufactured with additive techniques. CAx software will enable designers to create intricate lattice structures, lightweight components, and customized parts that enhance vehicle performance and reduce material waste. ● Sustainability and Electric Mobility The shift towards sustainable and electric mobility will require innovative vehicle designs that accommodate new powertrain technologies and optimize energy efficiency. CAx software will facilitate the integration of battery systems, electric drivetrains, and energy recovery systems into vehicle designs, ensuring that the transition to cleaner mobility is seamless and efficient. ● Human-Centered Design With an increasing focus on user experience, CAx software will evolve to prioritize human-centered design principles. This entails designing vehicles that prioritize safety, comfort, and accessibility for all passengers. Virtual reality and augmented reality tools will enable designers to simulate and optimize the in-car experience, leading to designs that cater to the diverse needs of

Read MoreThe Future of Energy Management: Trends and Innovations in EMIS

Table of content The Current Landscape Trends Shaping the Future Innovations on the Horizon Conclusion Effective energy management has become crucial in a world full of climate change challenges and rising demand for energy. Energy Management Information Systems (EMIS) have become essential instruments for lowering carbon footprints and attaining sustainable energy consumption. Looking ahead, it is evident that a convergence of cutting-edge technology and developing trends that promise to revolutionize how we produce, distribute, and use energy will determine the future of energy management. The Current Landscape Energy management has come a long way from manual tracking and reactive measures. Traditional methods of energy consumption monitoring lacked real-time insights and the ability to optimize energy usage. Enter EMIS – a comprehensive solution that integrates data collection, analysis, and decision-making to streamline energy consumption for commercial, industrial, and residential sectors. Currently, EMIS provides functions including remote monitoring, automated alarms, real-time data tracking, and specialized reporting. These features allow businesses to spot energy waste, implement efficiency measures, and track their advancement toward sustainable objectives. However, as technology advances and the demand for effective energy management grows, a fresh round of fashions and innovations is poised to reshape the industry. Trends Shaping the Future As the global landscape of energy consumption continues to evolve, several pivotal trends are emerging that promise to reshape how we manage, utilize, and sustain our energy resources. Let’s explore some of the key trends that are shaping the future of energy management: 1. Artificial Intelligence (AI) and Machine Learning (ML) AI and ML are poised to transform energy management by making it more predictive and adaptive. These technologies can analyze vast amounts of data collected from various sources, such as sensors and smart devices, to identify consumption patterns, anomalies, and optimization opportunities. This allows for the creation of predictive models that can anticipate energy demands and provide real-time recommendations for energy-saving actions. For example, AI-powered systems can automatically adjust HVAC settings based on occupancy patterns and weather forecasts, ensuring optimal comfort while minimizing energy use. 2. Internet of Things (IoT) The IoT revolution is bringing energy management to a new level of granularity. The proliferation of connected devices enables the collection of data from a multitude of sources, ranging from individual appliances to entire buildings. This data can be integrated into EMIS platforms to provide a holistic view of energy usage. Smart meters, sensors, and IoT-enabled appliances communicate with EMIS, allowing for precise tracking and control of energy consumption. This trend also promotes the development of demand-response systems, where energy use can be adjusted in real-time based on grid conditions, reducing strain during peak periods. 3. Blockchain Technology Blockchain technology holds promise in enhancing transparency, security, and efficiency in energy management. It can facilitate peer-to-peer energy trading, where individuals or organizations can buy and sell excess energy directly to one another. This decentralized approach empowers consumers to become prosumers, generating and distributing their energy while maintaining a transparent record of transactions. Blockchain also ensures data integrity in EMIS systems, reducing the risk of tampering or fraud. 4. Decentralized Energy Systems The future of energy management is moving away from centralized power generation towards decentralized systems. Distributed Energy Resources (DERs) like solar panels, wind turbines, and battery storage enable local energy production and consumption. EMIS platforms must evolve to incorporate these distributed assets, optimizing their usage and integrating them seamlessly into the energy grid. This shift promotes energy resilience, reduces transmission losses, and fosters a more sustainable and reliable energy ecosystem. 5. Energy-as-a-Service (EaaS) The concept of Energy-as-a-Service is gaining traction, where energy providers offer comprehensive solutions beyond electricity or gas supply. EaaS providers bundle energy with value-added services like energy audits, efficiency upgrades, and ongoing monitoring. EMIS will play a pivotal role in EaaS models, enabling providers to offer personalized recommendations and insights to customers. This approach aligns with the shift towards outcome-based solutions, focusing on delivering tangible energy savings and sustainability outcomes. Innovations on the Horizon As we stand on the cusp of a new era in energy management, a wave of innovative developments is poised to redefine how we interact with, harness, and optimize energy resources. Let’s delve into some of the groundbreaking innovations on the horizon for energy management: 1. Energy Forecasting and Optimization Future EMIS platforms will leverage AI and ML algorithms to forecast energy demands more accurately. These systems will analyze historical data, weather patterns, occupancy trends, and local events to predict energy consumption patterns. Organizations can optimize their operations, minimize energy waste, and reduce costs by anticipating peaks and valleys in demand. For instance, a manufacturing plant can adjust production schedules to coincide with periods of lower electricity demand, optimizing energy expenses. 2. Dynamic Pricing Integration EMIS platforms will integrate seamlessly with dynamic pricing schemes offered by energy providers. These schemes adjust energy prices based on real-time grid conditions and demand. EMIS, connected to smart meters and IoT devices, can automatically respond to these price signals. For instance, during periods of high energy demand, the system can adjust HVAC settings or delay non-essential processes to avoid peak pricing, leading to substantial cost savings. 3. Personalized Energy Efficiency As AI becomes more sophisticated, EMIS platforms will offer personalized energy efficiency recommendations to individuals and organizations. These recommendations will be based on a thorough understanding of consumption patterns, preferences, and goals. For homeowners, the system might suggest optimal thermostat settings and appliance usage schedules. Businesses could receive advice on lighting upgrades, equipment replacements, and workflow adjustments to reduce energy consumption while maintaining productivity. 4. Energy Gamification Gamification principles will be integrated into EMIS interfaces to encourage energy-saving behaviors. By turning energy efficiency into a game, users can compete with themselves or others to achieve energy reduction targets. Real-time feedback, rewards, and leaderboards can motivate individuals and teams to adopt sustainable practices. This innovation taps into human psychology, fostering a sense of accomplishment and competitiveness while contributing to overall energy conservation. 5. Energy Resilience and Disaster Preparedness With the increasing frequency of extreme weather events and grid disruptions, EMIS platforms will be critical in enhancing energy

Read MoreImproving Operational Efficiency with MES: A Deep Dive into its Benefits

Table of content Real-Time Visibility and ControlEnhanced Production Planning and SchedulingImproved Quality Control and TraceabilityStreamlined Inventory ManagementData-Driven Decision Making and Continuous ImprovementEnhanced Compliance and Regulatory Compliance Conclusion Operational effectiveness is crucial for companies trying to stay ahead in today’s cutthroat manufacturing environment. Manufacturing Execution Systems (MES) have changed the game by allowing producers to enhance production, streamline operations, and increase efficiency. This article thoroughly explores MES and explains how it can increase operational effectiveness in an organization. Manufacturers can use the power of MES to drive radical changes in their production processes by identifying and acknowledging the benefits of its implementation. Real-Time Visibility and Control The real-time visibility that MES gives manufacturers into their production activities enables them to monitor and manage every part of the manufacturing process. MES provides thorough insights into production indicators, machine status, work order progress, and resource use by combining data from numerous sources. This real-time visibility empowers firms to address bottlenecks, reduce downtime, and improve resource allocation. It also speeds up reaction times. Furthermore, MES facilitates centralized control over production processes, enabling manufacturers to standardize workflows, enforce best practices, and implement consistent procedures across multiple production lines or locations. By providing a unified view of operations, MES enables organizations to identify inefficiencies, streamline processes, and ensure adherence to quality standards and compliance requirements. Enhanced Production Planning and Scheduling Manufacturing Execution Systems (MES) enable enterprises to optimize their production processes, save lead times, and boost overall efficiency, revolutionizing production planning and scheduling. Resource allocation, capacity planning, and workload balancing are made possible by MES’s extensive features. By integrating real-time data on machine availability, labor capacity, and material availability, MES enables accurate production planning and scheduling. Manufacturers can optimize machine utilization, reduce idle time, and minimize changeover times, leading to increased throughput and reduced production cycle times. Additionally, MES enables dynamic rescheduling to accommodate unforeseen changes, such as rush orders or machine breakdowns, ensuring optimal production efficiency. Improved Quality Control and Traceability MES plays a pivotal role in improving quality control processes and ensuring product traceability throughout the manufacturing lifecycle. By capturing real-time data at every stage of production, MES enables manufacturers to monitor and control quality parameters, perform inspections, and enforce adherence to quality standards. Manufacturers can use automated data gathering and analysis using MES to spot and fix quality problems instantly. MES provides a framework for Statistical Process Control (SPC), allowing producers to track quality metrics, spot deviations, and quickly take corrective action. MES-driven quality control measures allow manufacturers to lower the amount of scrap, rework, and defects, improving product quality and customer satisfaction. By recording and storing complete data on materials, components, processes, and related data, MES also makes thorough product traceability possible. Manufacturers can swiftly pinpoint the underlying cause of a quality problem or product recall, carry out focused corrective actions, and lower the adverse impact on customers and brand reputation. Streamlined Inventory Management Manufacturers can optimize inventory levels, lower carrying costs, and enhance supply chain performance, thanks to MES’ all-inclusive inventory management solution. MES offers precise visibility into inventory levels, consumption rates, and material requirements through real-time data integration and analysis. By synchronizing production schedules, material availability, and customer demand, MES enables manufacturers to minimize stockouts and excess inventory. With accurate demand forecasting and just-in-time inventory management, manufacturers can achieve better inventory accuracy, reduce carrying costs, and optimize working capital. The automation of material replenishment procedures, the provision of real-time inventory updates, and the facilitation of seamless coordination between production, procurement, and warehousing operations are ways in which MES facilitates effective material flow and control. As a result, supply chain activities are streamlined, delays are reduced, and materials are always available at the appropriate time and in the appropriate quantity. Data-Driven Decision Making and Continuous Improvement Manufacturers who use MES have access to data-driven decision-making skills, allowing them to take advantage of insights and promote efforts for continuous improvement. Massive volumes of real-time production data are collected and analyzed by MES, which offers actionable insights that support well-informed decision-making. Manufacturers can spot trends, patterns, and performance measures that affect operational effectiveness through comprehensive analytics and reporting features. Key Performance Indicators (KPIs) and customizable dashboards provided by MES enable businesses to track several metrics, including Overall Equipment Efficiency (OEE), production yield, downtime, and quality. With the use of such data, manufacturers can highlight areas for improvement, focus on bettering them, and assess the results of changing their processes. MES also supports the deployment of continuous improvement processes such as Lean and Six Sigma. It allows firms to discover waste, variability, and non-value-added operations by offering real-time visibility into processes. This enables manufacturers to implement lean principles, promote process optimization, and foster a culture of continuous improvement throughout the firm. Enhanced Compliance and Regulatory Compliance Manufacturing Execution Systems (MES) implementation improves adherence to industry norms and regulations, ensuring that manufacturers fulfill the necessary criteria and uphold regulatory compliance. For maintaining and enforcing compliance with industry-specific rules like Good Manufacturing Practices (GMP), ISO standards, and certain quality certifications, MES offers a consolidated platform. Manufacturing Execution Systems (MES) ensure that manufacturers follow the appropriate regulations and maintain consistent compliance throughout their operations by combining quality control processes, documentation management, and audit trails. With MES, manufacturers can capture and store critical data related to production processes, materials, and quality control parameters. This data is readily available for audits, inspections, and regulatory reporting, ensuring transparency and accountability. MES facilitates efficient documentation management, automating the generation and storage of critical documents, including batch records, Standard Operating Procedures (SOPs), and quality control documentation. Conclusion Manufacturing Execution Systems (MES) provide businesses with a variety of advantages targeted at enhancing operational effectiveness. Through increased production planning, quality control, inventory management, data-driven decision-making, compliance management and real-time visibility and control, MES helps businesses streamline their operations, cut costs, and promote continuous development. Manufacturers can obtain a competitive edge in the dynamic production environment by deploying MES. Organizations can make data-driven choices, react swiftly to changes, and adhere to regulations, thanks to the comprehensive functions of MES. Manufacturers may streamline operations, boost productivity, provide high-quality goods, and maintain

Read MoreIntroduction to Manufacturing Execution Systems (MES): The Key to Streamlining Production

Table of content Understanding Manufacturing Execution Systems Benefits of Implementing Manufacturing Execution Systems Real-time VisibilityEnhanced Production EfficiencyQuality Control and ComplianceInventory ManagementTraceability and GenealogyPerformance Analysis and Continuous Improvement Implementing Manufacturing Execution Systems Overcoming Implementation Challenges of Manufacturing Execution Systems (MES) Change ManagementScalability and FlexibilityData Security and IntegrationVendor Selection and Partnership Conclusion Organizations are always looking for ways to increase production, save costs, and improve operational efficiency in today’s competitive manufacturing environment. To accomplish these objectives, Manufacturing Execution Systems (MES) have become a crucial technological option. Enterprise Resource Planning (ERP) systems and the shop floor are connected by MES, which gives manufacturers real-time visibility and control and facilitates manufacturing operations optimization. This article is a detailed introduction to Manufacturing Execution Systems (MES), exploring their functionalities, benefits, and their pivotal role in streamlining production processes. Understanding Manufacturing Execution Systems Manufacturing Execution Systems (MES) is a group of software programs created to coordinate and direct the performance of manufacturing operations on the shop floor. To enable smooth data transmission and real-time decision-making, MES is a central hub connecting numerous systems, including equipment automation, supervisory control and data acquisition (SCADA), and ERP. Production scheduling, order management, resource allocation, quality control, inventory management, and data collecting are among the functionalities offered by MES. Manufacturers may obtain insights, spot bottlenecks, and improve processes for greater efficiency and productivity using MES to collect and analyze data at various stages of the manufacturing process. Benefits of Implementing Manufacturing Execution Systems Implementing Manufacturing Execution Systems (MES) offers numerous benefits to manufacturers, driving improvements across the entire production process. Some key benefits include: Real-time Visibility MES provides real-time visibility into production data, enabling stakeholders to monitor and track operations, identify issues, and make data-driven decisions. This transparency enhances operational control and facilitates proactive problem-solving. Enhanced Production Efficiency MES enhances manufacturing operations by optimizing workflows, lowering manual error rates, reducing downtime, and increasing resource efficiency. Data gathering, scheduling, and quality control are all automated by MES, which also ensures that activities run smoothly and effectively. Quality Control and Compliance By gathering real-time data, conducting inspections, and enforcing compliance with industry norms and laws, MES provides strict quality control. By doing this, products are guaranteed to fulfill certain quality standards, lowering the likelihood of non-compliance and rework. Inventory Management MES provides real-time visibility into inventory levels, enabling manufacturers to optimize material flow, track stock levels, and minimize stock-outs or excess inventory. This streamlines supply chain operations, reduces carrying costs, and improves overall inventory accuracy. Traceability and Genealogy MES tracks and records detailed information about each product, including its components, processes, and associated data. This enables end-to-end traceability, making it easier to identify the source of issues, conduct recalls, and comply with regulatory requirements. Performance Analysis and Continuous Improvement MES captures comprehensive data on production performance, allowing manufacturers to analyze Key Performance Indicators (KPIs), identify inefficiencies, and implement targeted improvement initiatives. This facilitates a culture of continuous improvement, driving operational excellence. Implementing Manufacturing Execution Systems Implementing Manufacturing Execution Systems (MES) requires careful planning, collaboration, and adherence to best practices. The key steps in the implementation process include: Overcoming Implementation Challenges of Manufacturing Execution Systems (MES) Organizations must overcome a number of obstacles while implementing Manufacturing Execution Systems (MES) to achieve a successful rollout. Maximizing the advantages of MES in simplifying production requires understanding and overcoming certain implementation hurdles. Change Management Introducing MES involves significant changes in processes, workflows, and employee roles. Resistance to change and lack of employee buy-in can hinder successful implementation. It is essential to establish a comprehensive change management plan that involves effective communication, training programs, and engaging employees at all levels. Organizations can overcome resistance and ensure a smooth transition by addressing concerns, providing support, and fostering a positive attitude towards MES. Scalability and Flexibility Organizations must consider the scalability and flexibility of MES to accommodate future growth and evolving production needs. MES should be designed with modularity and extensibility in mind, allowing for easy integration with new technologies and adaptability to changing requirements. Choosing a flexible MES solution that can scale with the organization’s growth ensures long-term success and minimizes the need for disruptive system replacements in the future. Data Security and Integration Critical issues include safeguarding sensitive production data and ensuring secure integration with existing systems. Strong data security measures, including encryption, access controls, and regular vulnerability assessments, are necessary for MES implementation. Establishing safe data-sharing protocols and ensuring compliance with pertinent industry norms and standards need close cooperation with IT teams. Vendor Selection and Partnership Selecting the right MES vendor and establishing a strong partnership is crucial for successful implementation. Organizations should thoroughly evaluate vendors based on their industry expertise, track record, support services, and alignment with the organization’s goals. Collaborating closely with the chosen vendor, establishing clear expectations, and maintaining open communication throughout the implementation process is key to overcoming challenges and achieving successful outcomes. Conclusion Manufacturing Execution Systems (MES) have developed into essential tools for businesses aiming to increase productivity, streamline processes, and grow sustainably. MES improves productivity, quality, and decision-making by offering real-time visibility, control, and optimization of manufacturing processes. A successful manufacturing organization must deploy MES because of its advantages, which include improved quality control, increased production efficiency, and simplified inventory management. Adopting MES is a strategic decision for enterprises as they strive for operational excellence and competitiveness. Manufacturers may alter their manufacturing processes, lower costs, increase customer satisfaction and promote continuous improvement by leveraging MES. Manufacturers are well-equipped to handle the changing manufacturing landscape and prevail in the more fiercely competitive global market when they use MES as a cornerstone of their digital transformation plan.Ready to streamline your production processes with the power of Manufacturing Execution Systems (MES)? Partner with Prescient to implement a seamless MES solution tailored to your organization’s needs. Contact us today and revolutionize your production efficiency with Prescient’s expertise and cutting-edge technology.

Read MoreOvercoming Challenges: Implementing a Successful Digital Factory Strategy

Table of content Legacy System IntegrationData Management and InteroperabilityWorkforce Transformation and Skills GapCybersecurity and Data PrivacyEnsuring Return on InvestmentChange Management and Organizational Alignment Conclusion The digital factory has become a potent force for operational excellence, efficiency, and innovation in today’s quickly changing manufacturing market. The prospects for manufacturers are enormous because of the integration of cutting-edge technologies, automation, and data-driven processes in digital factories. A successful digital industrial plan can be difficult to implement, though. This article examines the main obstacles businesses experience while adopting and implementing digital manufacturing methods and offers suggestions on how this goal can be accomplished. Manufacturers may fully utilize the capabilities of digital factories and promote sustainable growth in the digital era by comprehending and addressing these problems. Legacy System Integration Integrating old systems with new technology and processes is one of the key difficulties in putting a successful digital factory plan into practice. Existing systems in many manufacturing businesses, such as ERP, MES, and machine control systems, are not built to communicate easily with digital technology. Integration of legacy systems necessitates thorough planning, assessment, and perhaps a phased approach. It is essential to outline the shortcomings and loopholes in the current systems and assess how well they work with emerging digital technologies. To achieve a seamless transition and reduce operational disruptions, a defined plan for integration that addresses data transfer, system compatibility, and process redesign is important. Data Management and Interoperability Data management and interoperability present significant challenges in the implementation of a digital factory strategy. Digital factories generate vast amounts of data from various sources, including sensors, machines, and other connected devices. Managing and harnessing this data effectively is crucial for deriving meaningful insights and driving data-driven decision-making. Manufacturers must create strong data governance frameworks in order to address data management difficulties. For this, it is necessary to specify data standards, data ownership, data security procedures, and data integration tactics. Adopting industry standards, such as the Manufacturing Enterprise Solutions Association’s (MESA) models or the Industrial Internet Consortium’s Reference Architecture (IIoT RA), can help with data transmission and interoperability across various systems. Another crucial step is to put in place a strong data analytics infrastructure. This entails using cutting-edge analytics tools, cloud-based platforms, and machine learning algorithms to examine and extract useful insights from the enormous volume of data generated in the digital factory. In order to guarantee data reliability, precision, and consistency, manufacturers also need to invest in data quality assurance procedures. Workforce Transformation and Skills Gap Digital factories need knowledgeable and flexible staff who can use new technologies, analyze data, and work in cross-functional teams. But closing the skills gap and modernizing the workforce presents a substantial obstacle to implementing a digital industrial strategy. Manufacturers should prioritize worker development and upskilling projects to overcome this issue. This includes funding training initiatives emphasizing data analytics, automation, digital literacy, and group problem-solving. Manufacturers can empower their employees to adopt digital technology, adjust to new roles and responsibilities, and drive digital transformation by giving them the skills and knowledge they need. A culture of creativity and constant learning must also be promoted. Manufacturers ought to foster a culture that values experimentation, knowledge exchange, and cross-functional cooperation. A culture of innovation can be cultivated, and staff members can be assisted in adapting to the evolving digital landscape by adopting a growth mindset and offering continuing assistance and mentorship. Cybersecurity and Data Privacy Implementing a digital manufacturing plan is significantly hampered by cybersecurity and data privacy issues due to our growing interconnectedness and reliance on digital technologies. Cyber dangers like data breaches, ransomware attacks, and intellectual property theft might strike digital factories. Manufacturers must prioritize effective cybersecurity measures to reduce cybersecurity risks. Strong access controls, encryption techniques, network security, and intrusion detection systems should all be put in place. Regular security audits, vulnerability assessments, and employee awareness training are also crucial to maintain a proactive and alert security posture. Data security, adherence to laws like the General Data Protection Regulation (GDPR), and industry-specific standards are also essential. Manufacturers are required to provide clear data privacy rules, ensure the security of data transmission and storage, and get consent for data gathering. Data protection measures are interwoven into the fabric of the digital factory strategy when privacy-by-design concepts are used. Ensuring Return on Investment Investing in digital factory technologies and infrastructure requires substantial financial resources. Organizations must carefully evaluate and plan their investments to ensure a positive Return on Investment (ROI). Demonstrating the value and benefits of digital factories is crucial for securing executive support and funding. To maximize ROI, organizations should conduct a comprehensive cost-benefit analysis, considering factors such as increased productivity, reduced downtime, improved quality, and operational efficiencies. Developing a clear business case, setting measurable goals, and establishing Key Performance Indicators (KPIs) will help track progress and reflect the impact of digitalization on the bottom line. Change Management and Organizational Alignment Change management and organizational alignment are critical aspects of implementing a successful digital factory strategy. The adoption of digital technologies and new ways of working can disrupt established workflows and create resistance within an organization. Therefore, effective change management is crucial to ensure a smooth transition and employee buy-in. In order to align and transform an organization, leadership is essential. It is crucial to explain the goals and advantages of digital manufacturing to employees, answering any doubts or worries they may have. Organizations may establish a setting that welcomes change and promotes innovation by fostering a culture of openness, collaboration, and continual learning. Furthermore, involving employees in the decision-making process and soliciting their feedback can generate a sense of ownership and commitment to the digital factory strategy. Regular communication, training, and coaching sessions help employees understand the value of digitalization and how it aligns with the organization’s goals and objectives. Conclusion Implementing a successful digital factory strategy is a complex undertaking, but the rewards are significant. By addressing key challenges, manufacturers can unlock the full potential of digital factories. Embracing a holistic approach that encompasses

Read MoreSustainable Manufacturing: How Digital Factories Contribute to Environmental Conservation

Table of content Digital Factories: Pioneering Sustainable Manufacturing Practices Energy Efficiency and Resource OptimizationEmission Reduction and Environmental ImpactWaste Reduction and RecyclingLife Cycle Assessment and Sustainable Product DesignRemote Monitoring and Predictive Maintenance Conclusion The industrial sector is undergoing a fundamental change as it moves towards sustainable practices at a time when environmental sustainability has assumed great importance. A digital factory, which harnesses cutting-edge technologies and data-driven processes to pioneer a greener future, is at the forefront of this transition. The manufacturing landscape is changing as a result of digital factories’ continuous dedication to environmental preservation. These factories not only contribute to a more sustainable earth through energy efficiency, emission reduction, waste management, and sustainable product design but also promote operational excellence and cost savings. Join us on this journey, where we explore how digital factories are revolutionizing manufacturing while making substantial contributions to environmental preservation. Digital Factories: Pioneering Sustainable Manufacturing Practices Digital factories significantly advance environmental preservation by enabling the adoption of sustainable manufacturing techniques. These factories are transforming the way manufacturing processes affect the environment through various programs and technology. Energy Efficiency and Resource Optimization Digital industries prioritize resource efficiency and energy conservation since they have a substantial positive environmental impact. These factories use a combination of smart technology, sensors, and real-time data analytics to maximize energy efficiency, reduce waste, and diminish the environmental impact of manufacturing operations. Implementing automatic energy management, installing intelligent lighting systems, and closely watching equipment are some ways to increase energy efficiency. Digital factories optimize energy use to cut down on greenhouse gas emissions and overall energy use, making manufacturing more environmentally friendly. Additionally, digital factories use advanced analytics to maximize resource usage. Manufacturers are able to identify improvement opportunities and execute waste-reduction strategies by examining data on material utilization, production techniques, and supply chain operations. As part of this, inventory levels should be optimized, scrap and rework should be decreased, and circular economy concepts should be adopted, which put an emphasis on material reuse and recycling. Emission Reduction and Environmental Impact In order to reduce emissions and the negative environmental effects of manufacturing processes, digital factories are essential. These factories increase efficiency through data-driven optimization and process control, which lowers emissions and pollutants. Digital factories use real-time data analytics to efficiently monitor and control emissions from a variety of sources, including production machinery and fleets of vehicles. Manufacturers may considerably reduce air and water pollution by streamlining production processes, cutting down on idle time, and putting emission control systems in place. Additionally, digital factories aggressively support environmentally friendly transportation methods. Manufacturers can optimize logistics routes, shorten transportation distances, and combine shipments using the power of data analytics. As a result, fuel use is reduced, and carbon emissions are reduced. Digital technologies also allow for remote monitoring and preventative maintenance, which reduces the need for unnecessary travel and the resulting environmental effects. Waste Reduction and Recycling Digital factories prioritize waste reduction and recycling, contributing to a circular economy model. These factories identify opportunities to minimize waste generation and implement recycling initiatives through data analytics and process optimization. Digital factories can find inefficiencies and put waste reduction strategies in place by examining data on material usage, inventory control, and manufacturing processes. This entails streamlining production schedules, reducing overproduction, and putting lean manufacturing practices—which seek to do away with non-value-added activities—into practice. Furthermore, digital factories promote recycling and the reuse of materials. Manufacturers can identify recyclable materials through advanced sorting techniques and material tracking systems and ensure they are properly segregated and sent for recycling. This reduces the reliance on virgin resources, conserves energy, and minimizes waste sent to landfills. Life Cycle Assessment and Sustainable Product Design Digital factories facilitate lifecycle assessment and sustainable product design practices. By leveraging data analytics and simulation tools, manufacturers can assess the environmental impact of their products throughout their lifecycle and make informed decisions to reduce their footprint. Manufacturers can assess many design options, materials, and production processes to determine those with the lowest environmental effect through digital simulations and virtual prototyping. This makes it possible for them to create goods that are more sustainable, taking into account things like energy usage, resource utilization, recyclable materials, and end-of-life disposal. Digital factories also facilitate product traceability and transparency. By capturing and analyzing data at each stage of the product life cycle, manufacturers can provide customers with information on the product’s environmental impact, enabling more informed purchasing decisions and fostering a culture of sustainability. Remote Monitoring and Predictive Maintenance Digital factories enable remote monitoring and predictive maintenance practices, which contribute to environmental conservation by reducing energy waste and optimizing maintenance activities. Remote monitoring allows manufacturers to gather real-time data on equipment performance and energy consumption without the need for on-site personnel. By leveraging sensors and connectivity, digital factories can remotely monitor machines, systems, and energy usage, enabling proactive identification of inefficiencies or abnormalities. This early detection allows for prompt corrective actions, minimizing energy waste and reducing the environmental impact. Predictive maintenance, made possible by data analytics and machine learning algorithms, also aids in the optimization of maintenance procedures and the reduction of unscheduled downtime. Digital factories can forecast maintenance needs and plan maintenance actions at the most advantageous periods by assessing historical data, performance patterns, and equipment health indicators. Using this method, superfluous preventive maintenance can be avoided, and the possibility of unexpected equipment failures or breakdowns decreases. As a result, resources, energy, and materials are saved, making the manufacturing process more sustainable. Conclusion Digital factories are driving sustainable manufacturing practices and playing a pivotal role in environmental conservation. Through energy efficiency, emission reduction, waste management, and data-driven optimizations, these factories are transforming the manufacturing landscape. By prioritizing resource optimization, adopting circular economy principles, and promoting sustainable product design, digital factories contribute to a more sustainable and environmentally responsible approach to manufacturing. Remote monitoring, predictive maintenance, and data-driven sustainability improvements enhance their positive impact. By embracing digital technologies and sustainability principles, manufacturers can achieve their production goals while minimizing their ecological footprint.

Read More