Professionalism and work ethics… "The level of professionalism and work ethic you bring to the table is simply great. The fact that clicked the most is when you took complete responsibility for our product development and the outcome is exactly what we desired. Thank you Prescient."

CAx Customization

Empowering Your Business with Efficiency and Innovation

Design Automation is a cutting-edge service revolutionizing industries and businesses around the world. Staying ahead of the curve is crucial in this fast-paced, competitive environment. Design automation is the key to unlocking efficiency, cost savings, and innovation in your company. Design automation is an invaluable tool for businesses to remain competitive in the modern market. It enables businesses to streamline operations, increase efficiency, and quickly respond to changing customer needs. Investing in design automation is an essential part of staying ahead of the competition. Explore the possibilities and benefits of Design Automation with us.

Our Design Automation Solution

Our Design Automation Solution offers a comprehensive set of tools and features tailored to revolutionize your company’s design and development processes. With a focus on efficiency, accuracy, and innovation, our solution comprises three key components:

Specialized Features

Our Design Automation Solution comes equipped with a range of specialized features designed to address the unique needs of your industry and projects. These features are meticulously crafted to empower your team and enhance their capabilities, ultimately driving productivity and success.

Validators/Checkers

Ensuring design compliance and adherence to industry standards is crucial for any project's success. Our Design Automation Solution includes sophisticated Validators and Checkers that rigorously analyze your designs, verifying their accuracy and compliance with relevant regulations. By automating this critical validation process, our solution streamlines workflows and minimizes errors, saving valuable time and resources.

Engineering Calculators

Complex engineering calculations can be time-consuming and error-prone if performed manually. Our Design Automation Solution incorporates powerful engineering calculators that handle intricate simulations and computations easily. By automating these calculations, our solution accelerates the design process and provides accurate results, empowering your team to make well-informed decisions efficiently.

Design Automation in Different Industries

Design Automation is used across various industries, driving progress and innovation in each sector.

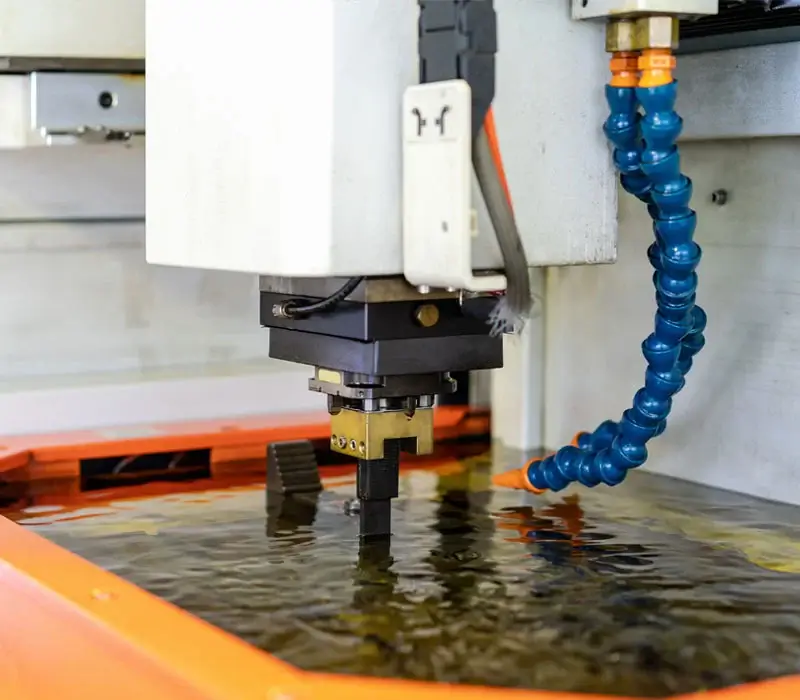

Manufacturing

Finds surface defects, assembly errors, and misaligned parts.

Electronics

Inspects circuit boards, solder joints, and semiconductor wafers.

Automotive

Detects paint flaws, scratches, and structural issues.

Pharmaceuticals

Checks packaging, labels, and tablet quality.

Benefits of Design Automation in your Business

Embracing Design Automation in your business can lead to a multitude of advantages that drive growth and profitability.

Faster Lead Times

Increased Accuracy

Lower Costs / Cost Savings

Improved Efficiency

Request a Quote Today

CASE STUDIES

Our Work Showcase

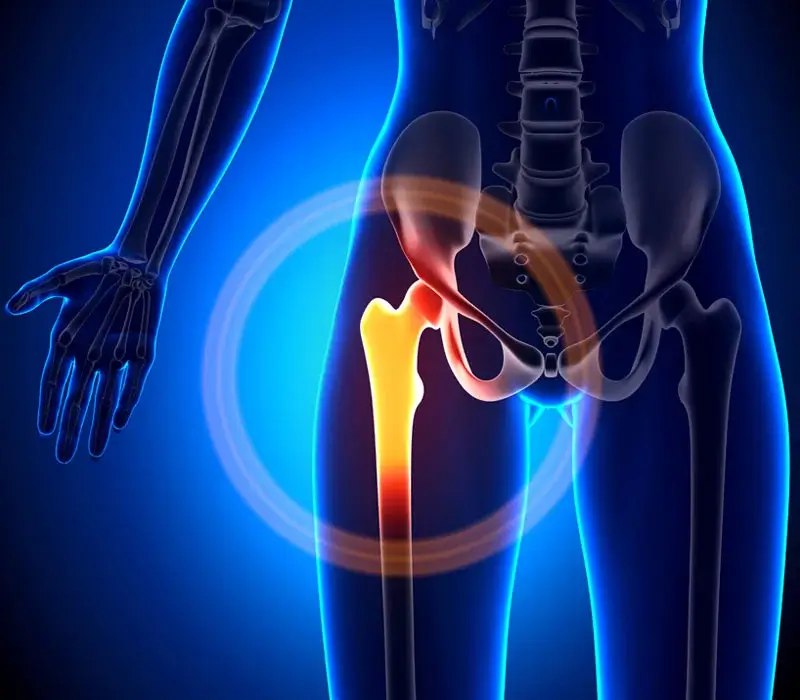

VMP Ortho

- Technology

CADMATE Takeoff

- Technology

EDM electrode

- Technology

UG NX

- Technology

Die Design

- Technology

Creating multiple automation utilities

- Technology

Address vehicular visibility

- Technology

Springback compensation

- Technology

TESTIMONIALS

What People Say

First on our list, without doubt … “I greatly appreciate the software development work you have been doing for Level 3 Inspection for all these years. Your team’s skills and your methodical approach to perfection, coupled with your high level of professionalism, have made the road pretty smooth for us to achieve our organizational and operational integration goals. If we have to recommend a competent partner we can totally depend on, your name would be the first on our list, without a doubt. Thank you Prescient!”

Bill Greene

CEO, Level 3 Inspection, USA

They are the exception... "We've been working with Prescient Technologies for quite a few years now, and they continue to provide quality work in a timely manner for a reasonable cost. They are the exception to the two out of three rule! (Fast, High Quality or Good Price, pick two)"

Bob Squier

President, 3D Scan IT, Inc., USA

There could not have been a better alternative… "It was a chance meeting with the Prescient team that set the ball rolling. Initially I was skeptical but their attitude “Together we can” inspired confidence. ”Hand-holding” by Prescient was exemplary and that was crucial for a start-up like ours. Our project in Orthopaedic navigation involved totally new objectives in as yet unexplored areas to be achieved with innovative steps in CAD domain. Few years down the line together we have added a chapter at the very edge of scientific knowledge. Thanks to Prescient our software idea has now evolved into a full-fledged market-ready product. Today I am convinced that there could not have been a better alternative."

Dr Vijay Panchanadikar

President, 3D Scan IT, Inc., USA

Professionalism and work ethics… "The level of professionalism and work ethic you bring to the table is simply great. The fact that clicked the most is when you took complete responsibility for our product development and the outcome is exactly what we desired. Thank you Prescient."

Stanley Sunny

Director, CADMATE SoftwareWhy Choose Prescient Technologies?

Expertise in Engineering Process Automation

Seamless Integration and Support

Successful Implementations

Measurable Results

What is Design Automation?

Design Automation is the utilization of software tools and frameworks to automate design processes, streamline workflows, and enhance efficiency across various industries.

How can Design Automation benefit my business?

Design Automation can lead to faster lead times, increased accuracy, lower costs, and improved overall efficiency, ultimately driving growth and competitiveness.

Is Design Automation suitable for small businesses?

Absolutely! Design automation can benefit businesses of all sizes by optimizing operations and unlocking innovation potential.

Can Design Automation be customized based on industry-specific needs?

Yes, our Design Automation solutions are tailored to meet the specific requirements of different industries, ensuring optimal results and outcomes.

How do I get started with Design Automation for my company?

Getting started is easy! Reach out to our team, and we will guide you through the process of implementing Design Automation in your business.

Section Title

Trending Blogs

Latest From Our Blog

- October 22 2024

- systemadmin

Remote Machine Monitoring vs. On-Site Monitoring

Monitoring machinery in manufacturing is like having a pulse on the equipment. It tells you when the machines are running smoothly and helps catch issues before they spiral out of control. Traditionally, monitoring was done on-site with technicians physically present to check every detail. But as technology advances remote machine monitoring is becoming the next logical step as it offers real-time data and control from anywhere. In this article, we’ll take a closer look at remote machine monitoring vs. on-site monitoring and explore their benefits, challenges, and differences. On-Site Monitoring On-site monitoring is the traditional way of keeping an eye on machines in a manufacturing facility. It involves technicians and engineers being physically present to oversee operations. This manual approach allows them to monitor performance metrics, inspect components, and respond immediately to any issues. The technicians are always on-site watching machine parameters such as temperature, power consumption, spindle speed, tool wear, and other essential items specific to their process. One of the main advantages of on-site monitoring is the ability to access machine data instantly. Technicians on the ground can quickly spot and address abnormalities and minimize downtime. Because this method doesn’t rely on internet connectivity, it’s particularly useful in locations where network stability might be an issue. On-site monitoring requires a significant investment in human power and also needs skilled workers who are adept at monitoring machines and processes. Even in plants that employ some level of digitization to observe the process, on-site personnel are needed to monitor things. For companies with multiple manufacturing sites, scaling up on-site monitoring can also become costly. Remote Machine Monitoring Remote machine monitoring is made possible by using the Industrial Internet of Things (IIoT) and cloud-based platforms. With remote monitoring, manufacturers can collect real-time data from machines across multiple locations, analyze performance, and address issues without needing technicians on-site. One of the main benefits of remote monitoring is its scalability. Companies with multiple manufacturing sites can monitor all operations from a centralized dashboard and reduce the need for on-site staff. The data collected can be analyzed to identify patterns, predict maintenance needs, and prevent potential failures. In the long run, remote machine monitoring is useful for condition monitoring of machinery and equipment. Detailed performance data can be streamed and stored over time with sensors and IoT devices installed on machines. This data can be used to assess performance and predict loss in efficiency or equipment failure well in advance. While there are downsides to remote machine monitoring in the form of network and cybersecurity challenges, it is better in every parameter compared to on-site monitoring. Remote Machine Monitoring Vs. On-site Monitoring (H2) Now let’s look at some of the key remote machine monitoring vs. on-site monitoring differences: Difference Parameter Remote Machine Monitoring On-Site Monitoring Cost Savings Remote monitoring offers greater cost efficiency compared to on-site monitoring. On-site monitoring requires continuous investment in personnel, training equipment, and operations. It can add up in terms of cost especially in large or multi-site operations. Scalability Scalability with remote monitoring is a major benefit as it allows manufacturers to oversee multiple sites from a centralized location. The need for physical presence and skilled technicians limits on-site monitoring. Since an extensive training period is involved, scaling is slower compared to remote monitoring. Data Collection and Analytics Remote monitoring systems are designed to collect vast amounts of data in real-time. The data is instantly updated to secure servers and is available for analytics almost instantaneously. On-site monitoring can gather high-quality data. However, uploading manual data to the MES or ERP systems takes time, which makes instantaneous analytics impossible. Maintenance and Downtime Management By using predictive analytics, remote systems can identify potential issues before they lead to machine failure. Maintenance than then be scheduled appropriately. On-site monitoring is often reactive and addresses issues only after they’ve occurred. Security and Compliance Remote monitoring systems rely on internet networks making them vulnerable to cybersecurity threats. However, remote service providers have robust security features for data transfer and storage. On-site monitoring faces physical security risks, data breaches from human error, and sabotage. Compliance with industry standards also has to be part of mandatory training for the personnel. Decision Making Remote monitoring makes instantaneous, data-driven decisions a common thing with manufacturers. Collecting real-time data from machines provides a complete overview of operations that can be analyzed to identify trends and optimize performance. On-site monitoring also supports data-driven decision-making. However, there is a significant lag from when the data is collected to when it is uploaded to the system for analytics. The lack of real-time insight makes it hard to detect immediate trends and early warning signs. Competitive Advantage for Manufacturers With the world already in Industry 4.0, manufacturers adopting remote monitoring have a competitive edge over others. Moreover, they are able to offer better maintenance to clients backed by robust data. Although on-site monitoring is effective in smaller localized operations, it may not offer the same level of flexibility and scalability. Manufacturers relying solely on on-site monitoring might find it more challenging to compete globally. To Wrap It Up While both remote and on-site machine monitoring play their roles in manufacturing, the future is remote. We have seen the differences in remote machine monitoring vs. on-site monitoring in terms of cost, security and data-backed decision-making, and there’s a clear winner. Manufacturers need to incorporate remote machine monitoring to stay competitive in an ever-growing digital production ecosystem. If you wish to learn more about how you can upgrade to remote machine monitoring, get in touch with our team and request a demo!

Read MoreTrending Blogs

Latest From Our Blog

- October 22 2024

- systemadmin

Remote Machine Monitoring vs. On-Site Monitoring

Monitoring machinery in manufacturing is like having a pulse on the equipment. It tells you when the machines are running smoothly and helps catch issues before they spiral out of control. Traditionally, monitoring was done on-site with technicians physically present to check every detail. But as technology advances remote machine monitoring is becoming the next logical step as it offers real-time data and control from anywhere. In this article, we’ll take a closer look at remote machine monitoring vs. on-site monitoring and explore their benefits, challenges, and differences. On-Site Monitoring On-site monitoring is the traditional way of keeping an eye on machines in a manufacturing facility. It involves technicians and engineers being physically present to oversee operations. This manual approach allows them to monitor performance metrics, inspect components, and respond immediately to any issues. The technicians are always on-site watching machine parameters such as temperature, power consumption, spindle speed, tool wear, and other essential items specific to their process. One of the main advantages of on-site monitoring is the ability to access machine data instantly. Technicians on the ground can quickly spot and address abnormalities and minimize downtime. Because this method doesn’t rely on internet connectivity, it’s particularly useful in locations where network stability might be an issue. On-site monitoring requires a significant investment in human power and also needs skilled workers who are adept at monitoring machines and processes. Even in plants that employ some level of digitization to observe the process, on-site personnel are needed to monitor things. For companies with multiple manufacturing sites, scaling up on-site monitoring can also become costly. Remote Machine Monitoring Remote machine monitoring is made possible by using the Industrial Internet of Things (IIoT) and cloud-based platforms. With remote monitoring, manufacturers can collect real-time data from machines across multiple locations, analyze performance, and address issues without needing technicians on-site. One of the main benefits of remote monitoring is its scalability. Companies with multiple manufacturing sites can monitor all operations from a centralized dashboard and reduce the need for on-site staff. The data collected can be analyzed to identify patterns, predict maintenance needs, and prevent potential failures. In the long run, remote machine monitoring is useful for condition monitoring of machinery and equipment. Detailed performance data can be streamed and stored over time with sensors and IoT devices installed on machines. This data can be used to assess performance and predict loss in efficiency or equipment failure well in advance. While there are downsides to remote machine monitoring in the form of network and cybersecurity challenges, it is better in every parameter compared to on-site monitoring. Remote Machine Monitoring Vs. On-site Monitoring (H2) Now let’s look at some of the key remote machine monitoring vs. on-site monitoring differences: Difference Parameter Remote Machine Monitoring On-Site Monitoring Cost Savings Remote monitoring offers greater cost efficiency compared to on-site monitoring. On-site monitoring requires continuous investment in personnel, training equipment, and operations. It can add up in terms of cost especially in large or multi-site operations. Scalability Scalability with remote monitoring is a major benefit as it allows manufacturers to oversee multiple sites from a centralized location. The need for physical presence and skilled technicians limits on-site monitoring. Since an extensive training period is involved, scaling is slower compared to remote monitoring. Data Collection and Analytics Remote monitoring systems are designed to collect vast amounts of data in real-time. The data is instantly updated to secure servers and is available for analytics almost instantaneously. On-site monitoring can gather high-quality data. However, uploading manual data to the MES or ERP systems takes time, which makes instantaneous analytics impossible. Maintenance and Downtime Management By using predictive analytics, remote systems can identify potential issues before they lead to machine failure. Maintenance than then be scheduled appropriately. On-site monitoring is often reactive and addresses issues only after they’ve occurred. Security and Compliance Remote monitoring systems rely on internet networks making them vulnerable to cybersecurity threats. However, remote service providers have robust security features for data transfer and storage. On-site monitoring faces physical security risks, data breaches from human error, and sabotage. Compliance with industry standards also has to be part of mandatory training for the personnel. Decision Making Remote monitoring makes instantaneous, data-driven decisions a common thing with manufacturers. Collecting real-time data from machines provides a complete overview of operations that can be analyzed to identify trends and optimize performance. On-site monitoring also supports data-driven decision-making. However, there is a significant lag from when the data is collected to when it is uploaded to the system for analytics. The lack of real-time insight makes it hard to detect immediate trends and early warning signs. Competitive Advantage for Manufacturers With the world already in Industry 4.0, manufacturers adopting remote monitoring have a competitive edge over others. Moreover, they are able to offer better maintenance to clients backed by robust data. Although on-site monitoring is effective in smaller localized operations, it may not offer the same level of flexibility and scalability. Manufacturers relying solely on on-site monitoring might find it more challenging to compete globally. To Wrap It Up While both remote and on-site machine monitoring play their roles in manufacturing, the future is remote. We have seen the differences in remote machine monitoring vs. on-site monitoring in terms of cost, security and data-backed decision-making, and there’s a clear winner. Manufacturers need to incorporate remote machine monitoring to stay competitive in an ever-growing digital production ecosystem. If you wish to learn more about how you can upgrade to remote machine monitoring, get in touch with our team and request a demo!

Read MoreTrending Blogs

Latest From Our Blog

- October 22 2024

- systemadmin

Remote Machine Monitoring vs. On-Site Monitoring

Monitoring machinery in manufacturing is like having a pulse on the equipment. It tells you when the machines are running smoothly and helps catch issues before they spiral out of control. Traditionally, monitoring was done on-site with technicians physically present to check every detail. But as technology advances remote machine monitoring is becoming the next logical step as it offers real-time data and control from anywhere. In this article, we’ll take a closer look at remote machine monitoring vs. on-site monitoring and explore their benefits, challenges, and differences. On-Site Monitoring On-site monitoring is the traditional way of keeping an eye on machines in a manufacturing facility. It involves technicians and engineers being physically present to oversee operations. This manual approach allows them to monitor performance metrics, inspect components, and respond immediately to any issues. The technicians are always on-site watching machine parameters such as temperature, power consumption, spindle speed, tool wear, and other essential items specific to their process. One of the main advantages of on-site monitoring is the ability to access machine data instantly. Technicians on the ground can quickly spot and address abnormalities and minimize downtime. Because this method doesn’t rely on internet connectivity, it’s particularly useful in locations where network stability might be an issue. On-site monitoring requires a significant investment in human power and also needs skilled workers who are adept at monitoring machines and processes. Even in plants that employ some level of digitization to observe the process, on-site personnel are needed to monitor things. For companies with multiple manufacturing sites, scaling up on-site monitoring can also become costly. Remote Machine Monitoring Remote machine monitoring is made possible by using the Industrial Internet of Things (IIoT) and cloud-based platforms. With remote monitoring, manufacturers can collect real-time data from machines across multiple locations, analyze performance, and address issues without needing technicians on-site. One of the main benefits of remote monitoring is its scalability. Companies with multiple manufacturing sites can monitor all operations from a centralized dashboard and reduce the need for on-site staff. The data collected can be analyzed to identify patterns, predict maintenance needs, and prevent potential failures. In the long run, remote machine monitoring is useful for condition monitoring of machinery and equipment. Detailed performance data can be streamed and stored over time with sensors and IoT devices installed on machines. This data can be used to assess performance and predict loss in efficiency or equipment failure well in advance. While there are downsides to remote machine monitoring in the form of network and cybersecurity challenges, it is better in every parameter compared to on-site monitoring. Remote Machine Monitoring Vs. On-site Monitoring (H2) Now let’s look at some of the key remote machine monitoring vs. on-site monitoring differences: Difference Parameter Remote Machine Monitoring On-Site Monitoring Cost Savings Remote monitoring offers greater cost efficiency compared to on-site monitoring. On-site monitoring requires continuous investment in personnel, training equipment, and operations. It can add up in terms of cost especially in large or multi-site operations. Scalability Scalability with remote monitoring is a major benefit as it allows manufacturers to oversee multiple sites from a centralized location. The need for physical presence and skilled technicians limits on-site monitoring. Since an extensive training period is involved, scaling is slower compared to remote monitoring. Data Collection and Analytics Remote monitoring systems are designed to collect vast amounts of data in real-time. The data is instantly updated to secure servers and is available for analytics almost instantaneously. On-site monitoring can gather high-quality data. However, uploading manual data to the MES or ERP systems takes time, which makes instantaneous analytics impossible. Maintenance and Downtime Management By using predictive analytics, remote systems can identify potential issues before they lead to machine failure. Maintenance than then be scheduled appropriately. On-site monitoring is often reactive and addresses issues only after they’ve occurred. Security and Compliance Remote monitoring systems rely on internet networks making them vulnerable to cybersecurity threats. However, remote service providers have robust security features for data transfer and storage. On-site monitoring faces physical security risks, data breaches from human error, and sabotage. Compliance with industry standards also has to be part of mandatory training for the personnel. Decision Making Remote monitoring makes instantaneous, data-driven decisions a common thing with manufacturers. Collecting real-time data from machines provides a complete overview of operations that can be analyzed to identify trends and optimize performance. On-site monitoring also supports data-driven decision-making. However, there is a significant lag from when the data is collected to when it is uploaded to the system for analytics. The lack of real-time insight makes it hard to detect immediate trends and early warning signs. Competitive Advantage for Manufacturers With the world already in Industry 4.0, manufacturers adopting remote monitoring have a competitive edge over others. Moreover, they are able to offer better maintenance to clients backed by robust data. Although on-site monitoring is effective in smaller localized operations, it may not offer the same level of flexibility and scalability. Manufacturers relying solely on on-site monitoring might find it more challenging to compete globally. To Wrap It Up While both remote and on-site machine monitoring play their roles in manufacturing, the future is remote. We have seen the differences in remote machine monitoring vs. on-site monitoring in terms of cost, security and data-backed decision-making, and there’s a clear winner. Manufacturers need to incorporate remote machine monitoring to stay competitive in an ever-growing digital production ecosystem. If you wish to learn more about how you can upgrade to remote machine monitoring, get in touch with our team and request a demo!

Read More