Best Remote Machine Monitoring Software for Manufacturing

- Home

- Blog Details

- October 17 2024

- systemadmin

Industry 4.0 has been long in the making, and manufacturers are positioning themselves digitally to squeeze more work and money out of their production processes. In modern digitized production, having the right remote machine monitoring software can make a lot of difference. At a fundamental level, the solution is meant to keep an eye on your equipment’s performance from anywhere so you can maintain smooth operations and respond quickly to any problems.

But with so many options in the market, how do you choose a solution that is best suited for your factory needs? This guide will walk you through the key features to look for in the best remote machine monitoring software. From real-time data tracking to advanced analytics and security, we’ll cover what you need to make an informed decision.

Table of Contents

ToggleKey Features to Look for in Remote Machine Monitoring Software

Here are some of the important things to look for in the best remote machine monitoring software:

1. Real-Time Data Monitoring

The days of manual machine monitoring are numbered. Real-time data monitoring is quickly becoming necessary for manufacturers as it enables continuous tracking of the machine’s performance. With instant information, you can monitor everything happening with your equipment throughout the production cycles and catch problems as they arise.

Instant alerts are helpful when something goes off track or an anomaly is detected. The system should detect and notify all set abnormal readings right away. This early warning mechanism is necessary to address problems before they escalate, avoid downtime, and prevent costly repairs.

2. Advanced Analytics and Reporting

Advanced analytics and reporting are basic features all monitoring tools should have. Business analytics is crucial to making timely decisions based on large data sets. Data analysis tools embedded in robust frameworks, for example, permit a manager to look through performance metrics to note trends, areas of weakness, or constraints. For instance, if your system signals frequent downtime in a certain machine, you can run diagnostics and identify what is causing it.

Customizable reporting features let you create reports that focus on what matters most to you. This could be anything from overall equipment effectiveness to specific maintenance metrics. The reports clearly show your operations, helping you make informed decisions and optimize your production processes.

3. Predictive Maintenance Capabilities

Predictive maintenance tools let you peek into the future performance of your equipment. They help you forecast potential failures before they happen by analyzing data trends and historical performance. For example, if a shaft in the machine is intermittently showing varying speeds, the belt drive may be slipping because of expansion. Diagnosing this problem at an early stage can help prevent a failure of the belt that can bring production to a halt.

The best remote machine monitoring software should integrate with the maintenance management systems without trouble or glitches. With well-performing software, the maintenance teams have reliable data and insights to take appropriate action.

4. User-Friendly Interface

A user-friendly interface for remote machine monitoring can go a long way in getting workers to engage with the system. It’s essential to have dashboards that are easy to navigate and provide a clear view of data without any confusion. An intuitive layout helps people quickly find what they need, so they’re not wasting time hunting for information.

Intuitive dashboards also speed up the onboarding time for new workers in the plant. Customizable views are also a plus, letting people set up the software just how they prefer it. It should highlight the metrics and features that are important for the process.

5. Integration with Existing Systems

When choosing remote machine monitoring software it’s crucial to look for its capability to integrate with your existing systems. The need of the hour is software that fits effortlessly into your current setup, whether it’s your ERP, MES, or any other machine control system you use. The right software should connect smoothly without compatibility issues, pulling in data and working with your existing tools. For example, if your monitoring software can easily sync with your MES, it helps streamline your data transfer to the cloud and keeps everything available at your fingertips.

6. Security Features

The software should have robust data encryption features to keep data safe at all times. Secure access controls should be there to ensure that only authorized personnel can view or modify data. Compliance with industry standards and regulations, such as OSHA, GDPR, or ISO certifications, is also mandatory. The best software always meets the necessary legal and security requirements.

7. Value for Money

The model’s pricing features will become the final consideration factor in all software implementation. Search for pricing structures that are clear and defined and do not involve any additional charges. For instance, useful features such as real-time data monitoring must be incorporated into the software at an affordable price. Further, maintaining customer support to be as reliable as the service they are providing for getting the best out of investments is also important.

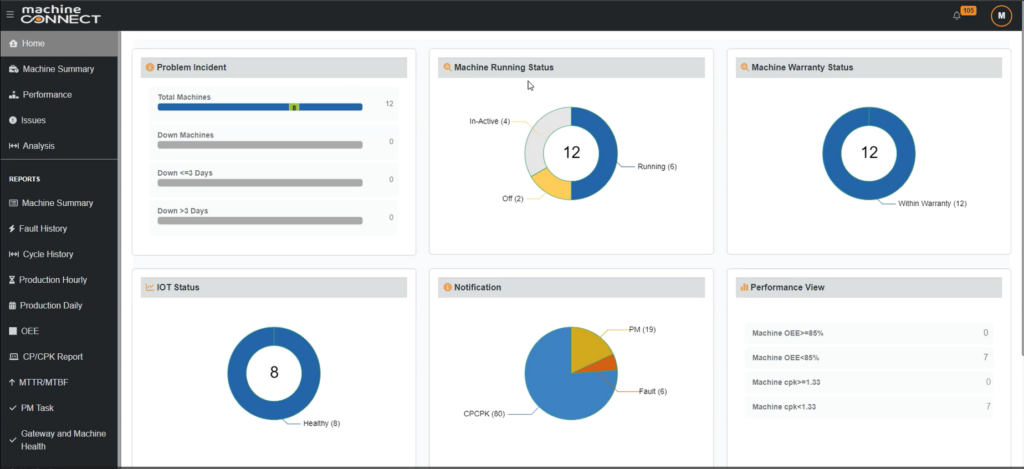

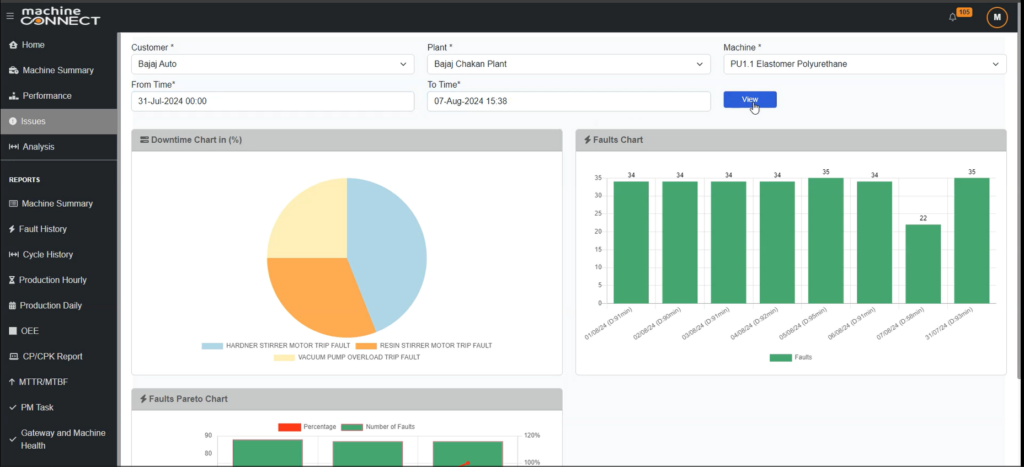

MachineConnect Can Transform Your Machine Monitoring with Advanced IoT Technology

MachineConnect is an advanced intelligent monitoring system designed to give you comprehensive oversight from your command center. With the software, you can stay on top of any faults or performance issues that arise in your production process.

By harnessing the power of Industrial Internet of Things (IIoT) technology, machineCONNECT provides critical data from your machines right at your fingertips. MachineCONNECT offers real-time tracking, fault detection, and performance analysis, all while effortlessly integrating with your existing systems. It also provides remote diagnostics and predictive maintenance, which helps you anticipate issues before they become problems. Moreover, it delivers valuable inputs for research and development and supports continuous improvement of your process.

To get a feel for how one of the best remote machine monitoring software in the market performs, get in touch with our team! Request a demo today!