A Comprehensive Guide to Implementing a Product Configurator in Manufacturing

- Home

- Blog Details

- July 14 2023

- admin

Table of content

Introduction

Benefits of Implementing a Product Configurator

Understanding Product Configurators

What is a Product Configurator?

Types of Product Configurators

Applications and Use Cases

Planning for Product Configuration

- Defining the Scope and Objectives

- Identifying Customization Options

- Analyzing Product Complexity

- Assessing Data and System Requirements

Selecting the Right Product Configurator Software

- Evaluating Software Providers

- Features and Functionality to Consider

- Scalability and Flexibility

- Integration with Existing Systems

Designing the Product Configuration Rules

Defining Product Constraints and Dependencies

Establishing Rule Hierarchy

Creating a User-Friendly Configurator Interface

- Visualizing Product Customization

- Designing an Intuitive User Interface

- Incorporating Real-Time Visualization

- Optimizing for Mobile and Web Platforms

Implementing and Integrating the Configurator

- Data Preparation and Validation

- Database and System Integration

- Testing and Quality Assurance

- Monitoring and Continuous Improvement

Ensuring a Seamless Customer Experience

- Customized Guidance and Support

- Real-Time Pricing and Quoting

- Order Management and Production Planning

- Post-Sales Support and Feedback

Overcoming Challenges and Pitfalls

- Managing Complex Product Configurations

- Data Accuracy and Integrity

- Balancing Customer Experience and Manufacturing Constraints

- Training and Change Management

Case Studies: Successful Product Configurator Implementations

Conclusion

Companies are continually looking for new, effective ways to deliver tailored products in the highly competitive manufacturing industry. A product configurator in manufacturing is a potent tool that enables these industries to visualize and design their preferred items.

This extensive manual seeks to give producers a thorough grasp of product configurators and a step-by-step process for successfully adopting them.

It also covers every step they need to fully realize the possibilities of a product configurator in production, from idea conceptualizing to choosing the appropriate software and ensuring seamless integration.

Introduction

Customers now want tailored items that cater to their interests, which has resulted in a paradigm shift in consumer demands for the manufacturing sector. Manufacturers are increasingly using product configurators to address this growing trend.

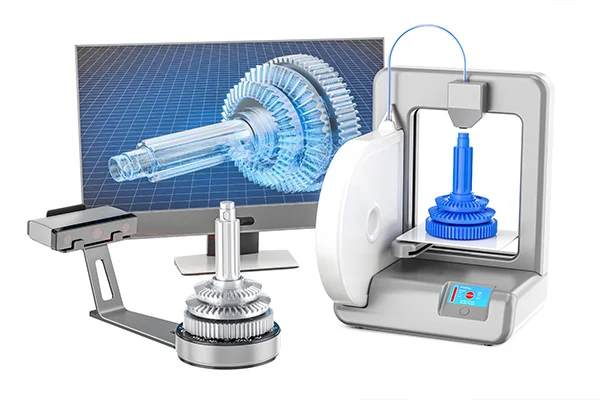

An interactive and immersive experience is provided by a product configurator, which is a software that allows customers to design products based on specified options and rules. This manual intends to help manufacturers comprehend how to successfully deploy a product configurator in manufacturing.

Benefits of Implementing a Product Configurator

Manufacturers can gain a wide range of advantages by using a product configurator. These include improved client interaction, more effective operations, shorter lead times, fewer mistakes, more sales conversions, and more efficient production procedures. A properly implemented product configurator may set a business apart from its competitors and boost customer loyalty.

Understanding Product Configurators

Understanding the principles is crucial before moving on to implementation. You can reap the advantages of product configurators and promote business growth by obtaining a thorough understanding of them.

What is a Product Configurator?

A product configurator allows customers to personalize and visualize products according to their preferences. They select and combine various features, options, and components to create a customized product. The configurator validates the chosen options against predefined rules and constraints to ensure feasibility and generate accurate specifications.

Types of Product Configurators

Product configurators can be categorized into three main types:

- Rule-based configurators: They use predefined rules and logic to guide the configuration process.

- Constraint-based configurators: They focus on defining constraints and dependencies among product features.

- Knowledge-based configurators: These configurators utilize artificial intelligence and machine learning to provide intelligent recommendations based on user inputs.

Applications and Use Cases

Additionally, product configurators are used in business-to-business (B2B) scenarios to configure intricate industrial machinery and equipment conveniently.

Planning for Product Configuration

Proper planning sets the stage for a successful product configurator implementation. By investing time and effort in the planning phase, you can ensure a well-defined roadmap for implementing your product configurator. It helps you achieve your desired outcomes efficiently.

Defining the Scope and Objectives

Before implementing a product configurator, it is essential to define the scope and objectives of the project. This involves identifying the target market, understanding customer preferences, and determining the level of customization to be offered. Clear goals and a well-defined scope will guide the implementation process and ensure alignment with business objectives.

Identifying Customization Options

The manufacturer must identify the customization choices available for a product’s design. This comprises adaptable features, elements, materials, colors, sizes, and other pertinent characteristics. You can choose the most desirable customization by carefully examining consumer needs, market trends, and rivals’ products.

Analyzing Product Complexity

The complexity of the product plays a crucial role in designing an effective product configurator. Manufacturers must assess the complexity of the products and evaluate if they can configure them within the desired constraints. Complex products often require more sophisticated configurator solutions and meticulous rule definitions.

Assessing Data and System Requirement

A thorough understanding of data needs and system integration helps to implement a product configurator. Manufacturers should assess their current data infrastructure, which includes product details, costs, available stock, and manufacturing capacities.

It’s vital to determine appropriate integration points with current enterprise systems. These include ERP (Enterprise Resource Planning) and CRM (Customer Relationship Management).

Selecting the Right Product Configurator Software

The correct software must be chosen in order for your product configurator installation to succeed. You can then support the goals of your business and provide a solid foundation for customization and efficiency. Let’s review some crucial elements:

Evaluating Software Providers

Manufacturers should take into account elements like the vendor’s experience, industry knowledge, track record, and customer feedback. Selecting a dependable, seasoned vendor with a solid, scalable solution is essential.

Features and Functionality to Consider

Manufacturers should evaluate the features and functionality of different product configurator software solutions. Key features include a user-friendly interface, real-time visualization, 3D modeling, and dynamic pricing. They should also check for automated bill of materials generation, integration capabilities, and reporting and analytics tools.

Scalability and Flexibility

Software for product configuration should be scalable to enable future expansion. It should also be adaptable to changing consumer expectations. Additionally, it should be adaptable to shifting market trends, product configurations, and corporate procedures. It should also be able to manage big product catalogs and support many product lines.

Integration with Existing Systems

Seamless integration with existing enterprise systems is critical for efficient operations. The product configurator software should integrate smoothly with ERP, CRM, PLM (Product Lifecycle Management), and other relevant systems. It ensures accurate data synchronization, efficient order management, and streamlined production processes.

Designing the Product Configuration Rules

A successful product configurator’s foundation consists of effective configuration rules. Let’s examine several configurators and show how to set dependencies and rules. Offer accurate and practical setups and give clients a seamless customization experience by defining rule hierarchies and limitations.

Rule-Based Configurators

Rule-based configurators utilize predefined rules and logic to guide the configuration process. Manufacturers need to define these rules, which include compatibility constraints, dependencies among features, and valid combinations. Ensure the rules accurately represent the product’s configuration possibilities while preventing invalid or impractical combinations.

Constraint-Based Configurators

Constraint-based configurators focus on defining constraints and dependencies among product features. These constraints can be in the form of logical rules, mathematical equations, or conditional statements. Always identify the dependencies and constraints between different features and establish validation mechanisms. It helps the configurator to generate feasible and valid configurations.

Knowledge-Based Configurators

Knowledge-based configurators leverage artificial intelligence and machine learning techniques to provide intelligent recommendations based on user inputs. These configurators learn from historical data, user preferences, and expert knowledge to guide the configuration process.

Manufacturers need to provide training data, define algorithms, and continuously update the knowledge base to enhance the configurator’s accuracy and recommendation capabilities.

Defining Product Constraints and Dependencies

Manufacturers must distinctly outline the limitations and dependencies between various product aspects to build a configurable product. It’s vital to map out the relationships and constraints that exist inside the product configuration space. These restrictions can be accurately defined by thoroughly examining product requirements, engineering specifications, and design constraints.

Establishing Rule Hierarchy

In complex product configurations, establishing a rule hierarchy becomes crucial. Manufacturers need to prioritize rules based on their importance and impact on the product configuration. It ensures that conflicting rules are resolved effectively for the configurator to provide consistent and logical recommendations.

Creating a User-Friendly Configurator Interface

Delivering a seamless and interesting client experience largely depends on the user interface. In this part, we’ll discuss how a user-friendly configurator interface can improve customer satisfaction while streamlining the modification process.

Visualizing Product Customization

The user experience of the product configurator is improved with a visually appealing and dynamic interface. Customers may precisely envision their customizations when visual elements. High-quality product pictures, 3D modeling, and real-time rendering are used. This increases participation and aids in customers’ decision-making.

Designing an Intuitive User Interface

The configurator interface needs to be simple to use and intuitive. Customers should be guided through the configuration process with alternatives and choices presented in an intelligible and straightforward way. The user interface ought to be simple to use, with a logical flow and simple controls.

Incorporating Real-Time Visualization

Customers can view their customizations dynamically, thanks to real-time visualization. The configurator should change the visual depiction of the product in real-time depending on various choices. Therefore, customers have the opportunity to make informed judgments.

Optimizing for Mobile and Web Platforms

It is crucial to optimize the product configurator for both mobile and web platforms in the current digital age. The user interface must be flexible and responsive to various screen sizes and resolutions. Customers utilizing a variety of devices, including smartphones, tablets, and desktop PCs, are guaranteed accessibility and ease.

Implementing and Integrating the Configurator

Realizing the full potential of your product configurator depends on the implementation and integration phase. Let’s explore the process’ operational details in this part. By adhering to these recommendations, you may guarantee a smooth and successful deployment of your configurator. You can provide improved performance and simplified operations.

Data Preparation and Validation

Before implementing the product configurator, manufacturers need to ensure the accuracy and integrity of their product data. This involves cleaning and validating the data, resolving any inconsistencies, and mapping it to the configurator’s data structure. Data preparation is crucial for generating accurate configurations and preventing errors during the customization process.

Database and System Integration

The product configurator should seamlessly integrate with existing databases and systems to ensure data synchronization and efficient workflow. Integration with ERP, CRM, and PLM systems enables seamless communication between the configurator, order management, inventory control, and production planning systems. It also facilitates accurate pricing, real-time inventory updates, and order tracking.

Testing and Quality Assurance

Thorough testing and quality assurance are essential before deploying the product configurator. Manufacturers should conduct rigorous testing to validate the configurator’s functionality, accuracy, and performance. This includes testing different configuration scenarios, validating data integrity, and ensuring compatibility across multiple platforms and devices.

Monitoring and Continuous Improvement

Post implementation, manufacturers should establish a monitoring system to track its performance, usage patterns, and customer feedback. Regular monitoring allows for identifying and resolving any issues or bottlenecks promptly. Continuous improvement involves analyzing data, identifying trends, and making iterative enhancements to the configurator. It helps optimize its effectiveness and customer satisfaction.

Ensuring a Seamless Customer Experience

The success of a product configurator is highly dependent on the customer experience. Let’s examine ideas and see how to give customers a seamless and positive experience:

Customized Guidance and Support

To provide a seamless customer experience, manufacturers should offer guidance and support throughout the configuration process. Clear instructions, tooltips, and contextual help can assist customers in making informed choices. Additionally, incorporating live chat or customer support features can address any queries or concerns promptly.

Real-Time Pricing and Quoting

Integrating real-time pricing and quoting capabilities into the configurator instantly shows the cost implications of their customizations. Manufacturers should ensure that the pricing engine accurately calculates costs based on selected options, quantities, discounts, and other factors. It fosters trust and enables customers to make purchasing decisions confidently.

Order Management and Production Planning

Efficient order management and production planning are crucial for a seamless customer experience. The configurator should seamlessly transmit the configuration details to the order management system. The procedure triggers the necessary workflows and processes. Integration with production planning systems allows for streamlined production scheduling, material procurement, and timely delivery.

Post-Sales Support and Feedback

Post-sales support becomes essential after a customer completes a configuration and places an order. Manufacturers should provide updates on order status, delivery tracking, and post-sales support. Collecting feedback from customers regarding their experience with the configurator can help identify areas for improvement. It also helps enhance future iterations of the product configurator.

Overcoming Challenges and Pitfalls

Implementing a product configurator can present unique challenges. Let’s explore common obstacles, discover practical solutions to overcome these challenges, and ensure successful product configurator implementation.

Managing Complex Product Configurations

Complex products with numerous customization options pose challenges in designing and implementing a configurator. Manufacturers should analyze the complexity of their products and strike a balance between customization flexibility and configurator usability. Employing advanced configurator techniques, such as constraint solvers or artificial intelligence, can help address complexity challenges effectively.

Data Accuracy and Integrity

Maintaining accurate and consistent product data is crucial for a successful product configurator implementation. Manufacturers must establish data governance practices to ensure data accuracy, integrity, and consistency across various systems and databases. Regular data audits and validation processes are essential to prevent errors and discrepancies.

Balancing Customer Experience and Manufacturing Constraints

While providing extensive customization options, manufacturers must also consider manufacturing constraints, such as feasibility, costs, and lead times. Striking a balance between customer experience and manufacturing capabilities ensures that the results are both desirable for customers and feasible for production.

Training and Change Management

Implementing a product configurator requires training employees and stakeholders on its usage, capabilities, and benefits. Adequate training programs should be developed to familiarize sales teams, customer support staff, and other relevant personnel with the configurator. Employ change management strategies to ensure smooth adoption and acceptance of the configurator across the organization.

Case Studies: Successful Product Configurator Implementations

Learn from real-world case studies of successful product configurator implementations across industries. You can highlight their positive impact on customer satisfaction, sales conversions, and manufacturing efficiency.

Automotive Industry

Automotive manufacturers have successfully implemented product configurators to enable customers to personalize their vehicles. Configurators allow customers to select options for exterior color, interior features, accessories, and more. By implementing configurators, well-known automotive brands have seen increased customer engagement, improved sales conversions, and streamlined production processes.

Furniture Manufacturing

Furniture producers use product configurators to provide specialized options for upholstery, coatings, measurements, and styles. Customers can use configurators to see their personalized furniture pieces and make better judgments. After introducing configurators, furniture makers have seen enhanced manufacturing productivity, decreased order errors, and higher customer satisfaction.

Electronic Appliances

Electronic appliance manufacturers use configurators to allow customers to personalize devices by selecting various specifications. These include screen size, memory, processor, and other features. Configurators have enhanced the customer experience by providing accurate product visualizations and real-time pricing. Manufacturers have experienced increased sales and improved production planning accuracy through configurator implementations.

Conclusion

The manufacturing sector gains a lot from implementing a product configurator in manufacturing, including improved client interaction, increased operational effectiveness, and simpler production procedures.

Manufacturers can successfully implement a product configurator that boosts sales and enhances customer satisfaction. They can achieve competitive differentiation by adopting a comprehensive approach. It commonly includes defining the scope, choosing the appropriate software, designing configuration rules, and creating a user-friendly interface.

Manufacturers use the potential of product configurators to improve their manufacturing capabilities in today’s highly configurable market. It includes careful planning, reliable software selection, and efficient integration.

Ready to revolutionize your manufacturing process? Experience the power of Prescient today and unlock the full potential of product configurator in manufacturing. Request a demo now and see how Prescient Technologies can streamline your operations to deliver unparalleled customer satisfaction.Take advantage of this opportunity to stay ahead of the competition. Take the first step towards implementing a comprehensive product configurator in manufacturing by contacting us today.

- adminhttps://www.pre-scient.com/author/webwideit/

- adminhttps://www.pre-scient.com/author/webwideit/

- adminhttps://www.pre-scient.com/author/webwideit/

- adminhttps://www.pre-scient.com/author/webwideit/