KBE Methodology for Product Design and Development

- Home

- Blog Details

- June 9 2023

- admin

Table of content

Introduction

The KBE Methodology: An Overview

The Benefits of KBE in Product Design and Development

- Improved Efficiency and Speed

- Enhanced Product Quality

- Increased Collaboration and Reusability

- Cost Reduction

Application of KBE in Product Design and Development

Challenges and Considerations

Overcoming Resistance to Automation

The Future of Manufacturing and Vision-Based Inspection

Conclusion

Introduction

Businesses continuously seek ways to enhance their product design and development processes in today’s fast-paced, cutthroat business environment. Knowledge-Based Engineering (KBE) is one methodology that has drawn much interest.

KBE streamlines the product development lifecycle and boosts overall effectiveness by combining technical expertise, CAD, and AI approaches. This article investigates the KBE approach, its advantages, and how it might be used to build new products.

The KBE Methodology: An Overview

Knowledge-Based Engineering (KBE) incorporates knowledge from diverse fields into computer- based systems. Engineers can produce novel items quickly because of the automation of design and engineering procedures made possible by these systems.

KBE uses the capabilities of expert systems, rule-based reasoning, and artificial intelligence to capture and apply engineering knowledge over a product’s lifecycle.

The Benefits of KBE in Product Design and Development

The Knowledge-Based Engineering (KBE) methodology can be adapted to create products with various benefits. KBE enables organisations to accomplish their objectives more quickly and successfully.

Let’s explore KBE’s advantages, revolutionising how things are created, developed, and released onto the market.

Improved Efficiency and Speed

KBE makes it possible to automate time-consuming, repetitive design procedures. Engineers can build designs, run simulations, and assess options fast by utilising pre-existing knowledge and regulations. This quickens the product development process, cutting down on time to market and giving the company a competitive edge.

Enhanced Product Quality

KBE systems enforce design limitations and regulations, reducing mistake rates and guaranteeing adherence to industry standards. KBE lessens the possibility of design mistakes by integrating technical expertise into the design process, improving the overall quality and dependability of the finished product.

Increased Collaboration and Reusability

KBE encourages communication and cooperation between engineering teams. All stakeholders will easily access design knowledge once it has been collected and organised in a central repository. This promotes reusability and enables engineers to draw on their prior expertise and successful ideas.

Cost Reduction

KBE’s automated features reduce manual iterations, reducing labour expenses and associated overhead. KBE aids in avoiding expensive design revisions at later phases of product development by minimising mistakes and optimising design decisions. Further lowering costs is made possible by the reuse of information and design elements.

Application of KBE in Product Design and Development

There are many opportunities when Knowledge-Based Engineering (KBE) is used in the design and development of products. KBE enables engineers to optimise designs, guarantee compliance with standards, and streamline the overall development workflow by interacting with CAD, simulation, and analytic tools. This section will examine how KBE is revolutionising product design and development by transforming how things are developed, validated, and ready for manufacturing.

Conceptual Design

KBE provides design templates, rule-based reasoning, and simulation tools to aid in the conceptualisation stage. Under established guidelines and limitations, engineers may quickly investigate potential design solutions, assess their performance, and come to wise conclusions.

Detailed Design

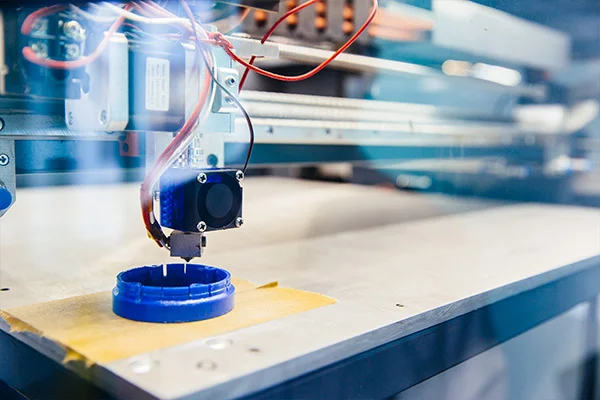

KBE streamlines the creation of 3D CAD models, automates geometric and parametric modelling, and maintains adherence to design standards during the detailed design process. By taking into account various aspects, including material selection, manufacturability, and assembly requirements, it enables engineers to optimise designs.

Simulation and Analysis

Vision-based inspection systems can validate proper component alignment and positioning in intricate manufacturing lines. To ensure exact assembly and lower the possibility of defective or out- of-place items, they can compare acquired photos against predetermined templates. Early detection of faults allows producers to avoid problems later on and enhance overall product quality.

Design Validation and Verification

Engineers can validate designs using KBE systems against industry standards, regulatory requirements, and design specifications. KBE makes sure that products fulfil safety, quality, and performance standards before they move into production by automating compliance inspections.

Challenges and Considerations

Although vision-based inspection systems have several benefits for production, they are difficult to implement. To achieve successful integration and ideal results, these elements must be addressed. Let’s examine the difficulties and vital elements to consider while implementing vision-based manufacturing inspection.

Overcoming Resistance to Automation

Although there is no denying the advantages of vision-based inspection systems, some manufacturers could be reluctant to adopt automation due to worries about job loss and up-front expenditures. It is crucial to understand that automation does not always imply the replacement of human labour. Instead, it enables them to concentrate on higher-value duties like inspecting inspection data, streamlining processes, and enhancing quality.

Furthermore, long-term cost savings and increased productivity can benefit more than the initial investment in vision-based inspection equipment. When weighing the deployment of these technologies, manufacturers should consider the return on investment (ROI) and potential competitive advantages.

The Future of Manufacturing and Vision-Based Inspection

Automation is the key to the success of manufacturing in the future, and vision-based inspection is leading this change. These systems will grow more potent, precise, and adaptable as technology develops. The effectiveness and capacities of vision-based inspection in manufacturing will be further improved by integration with other developing technologies, including robotics, the Internet of Things (IoT), and augmented reality.

Vision-based inspection technologies will maintain product quality and reduce environmental impact as the industry prioritises sustainability and waste reduction. Manufacturers may reduce waste and help create a more sustainable manufacturing ecosystem by identifying problems early in production.

Conclusion

The manufacturing sector is changing because vision-based inspection systems offer precise, effective, and reasonably priced quality control solutions. By embracing automation, manufacturers can obtain greater precision, increased efficiency, and lower costs. By utilising AI and machine vision technologies, businesses can streamline processes, enhance product quality, and gain a competitive edge in the global market.

Ready to revolutionise your manufacturing processes with the vision-based inspection? Contact Prescient today to unlock the power of automation, accuracy, and efficiency in quality control.