Reverse Engineering: Outsourcing and Beyond

- Home

- Blog Details

- January 17 2019

- admin

all know reverse engineering is an economical approach towards product development & innovation, which manufacturers often utilize to evaluate and redesign competitor products. Reverse Engineering services involve understanding the product design, system integrity, and manufacturing processes involved to realize the potential required to build a similar or improved product version. The reverse engineering technique is best suitable for producing design data and related technical manuals for products that no longer have any design information. The entire work process involves engineers studying every design feature, associated manufacturing processes, and tools needed for product development and storing information. After digitizing the complete information, suitable design modifications are carried out as per requirements. However, to get things right, one should have an efficient and dedicated engineering team, the right software, hardware tools, etc., which seems difficult to have within the organization.

FAQs

What is Reverse Engineering?

The Process by which a man-made object is dismantled to reveal its architecture, designs, or to extract knowledge from the object to know about its functioning and structural integrity.

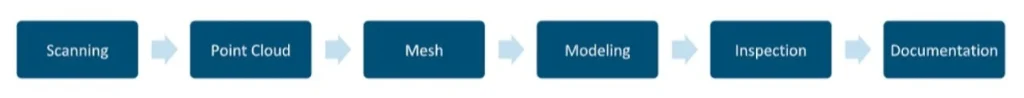

What is a typical CAD Reverse Engineering process?

A typical CAD reverse engineering involves:

What are the three stages of Reverse Engineering?

What is the future of Reverse Engineering?

Reverse engineering found its use in various industries gradually, as more and more industry leaders adopted this approach and implemented the same, thereby easing out their own work process.

Here comes the advantage of outsourcing reverse engineering projects where the activities can significantly reduce the cost of product development and burden the engineers who can focus on developing innovative design solutions for the product.

Reverse engineering services outsourcing might invoke some hesitancy. To address it, here are some of the crucial benefits of outsourcing reverse engineering projects:

- Outsourcing can bring in a global pool of talent with a myriad of innovative ideas that can assist in product design and development without investing in infrastructure and resources.

- As the in-house resource can focus on R&D, it dramatically helps improve the productivity of an organization.

- Product development time reduces considerably.

- Hiring an outsourcing partner who matches the requirement scale dramatically enhances the organization’s capability.

- RE outsourcing presents a scope to develop the product at a competitive price since the development cost is considerably less.

Still have more questions, ask us

Prescient Technology’s reverse engineering expertise has helped companies meet their designing and innovative demands. If you wish to know more, just click the button below.

Points to keep in mind while outsourcing reverse engineering services

As feasible as reverse engineering outsourcing sounds, there are specific steps to follow and factors to consider. Few crucial points to discuss when outsourcing reverse engineering services are as follows:

- The objective of reverse engineering as your provider needs to know your goals to suggest a cost-effective solution.

- Whether reverse engineering has to be for design intent or as-built depends solely on the organization’s end goal.

- What kind of measurement data should be approached, and to what extent the accuracy of measurement should be implemented, depending on organization plans.

- The original object is often disassembled or even destroyed for obtaining the most accurate measurements. Whether to go ahead with such a step or keep the actual product intact for future reference is something an organization should carefully decide on.

- What tools to be used for digitizing the final date, like desired software with its version to suit the complete development ecosystem.

Choosing a Vendor

After finalizing the decision to outsource reverse engineering service, the next vital step to consider is choosing a vendor. A responsive and efficient vendor makes all the difference. Finding a professional vendor with a high level of efficiency and even heightened work ethic is a complex but satisfying process. Be aware that once you are engaged with a vendor, it becomes a little difficult to break the deal and discontinue ‘business’ with the existing vendor. So choose carefully but commit completely after the contract.

When a vendor has been finalized, the organization issues a request for quotation (RFQ). RFQs are created to invite suppliers to a bidding process to bid on specific services/products. The organization should also take a legal approach and have the service provider’s non-disclosure agreement (NDA). This is done to prevent unlawful, authorized distribution, or illicit product adoption.

Now that the legal approach and paperwork have been taken care of, the organization sends the physical product to the service provider or the scanned files, depending on the company’s needs. The vendor is also supplied with measurement specifications and related industry standards to follow. Eventually, the vendor creates a digital format and sends it back to the organization for further design modification or innovation investigations.

For manufacturers, reverse engineering is a profitable strategy in today’s competitive scenario; however, outsourcing brings along the other benefits that ensure the product development process remains cost-effective. Prescient Technologies is adept at providing outstanding reverse engineering services and has extensive experience in the end-to-end process, so feel free to contact us today.