AI-ML Engineering Problems

- Home

- Blog Details

- July 13 2021

- admin

Artificial Intelligence (AI), Machine Learning, and Deep Learning have been extensively used for more than a decade but largely remained confined to areas such as voice recognition, image reconstruction, image/signal processing, and output prediction.

Such algorithms have seen limited usage in engineering domains such as thermal management, electronics cooling industries, fluid dynamics prediction inside the engine or over a bonnet, aerodynamics, and fluid dynamics problems across an aero-foil or turbine engine.

The delicate relation between AI ML and engineering can be better explained with two specific terms – A priori knowledge and posteriori knowledge. Since the time of Emmanual Kent, western philosophy has defined A priori knowledge as something which is attained from reason and independent of particular experiences. On the contrary, posteriori knowledge is derived from real evidence that has to be considered authentic.

It means A priori knowledge is not circumstance-centric but instead follows a set of pretty universal rules. Fundamental concepts of thermodynamics, electromagnetism, mechanical, and material properties are highly quantitative. They stick to a predetermined route rather than a vast stock of different scenarios.

Engineering Problems Requirements

Every problem related to engineering emphasizes the below-mentioned parameters:

High Accuracy Levels – Every endeavor starts with a model in the early stages. The model undergoes various physical applications and virtual simulations. It is done to gather all sorts of data to determine the proposed workability of the model and improvise areas. The model goes through several stages of scrutiny until high accuracy levels are achieved. AI ML works more on input feeding, and the outputs fluctuate every given time.

Function Over Feel – Engineering problems ask for the accurately intended functionality of a model. Feel of the component is never the priority. Every process applied to a model at every stage makes sure the intended functioning is obtained. As mentioned before, it is more linear. On the other hand, AI ML targets more on the feel, which varies with different situations.

High Repeatability and Predictability – An engineering task involves a high repetition of activities and the desired outcome is already known. One cannot simply predict an AI ML output, and as a result, for a conventional model in engineering, AI ML is not suitable.

However, recent years have witnessed increased usage of AI ML in the engineering sector, which is attributed to the following change in trends:

- Keeping up with rapid advancements to address consumer needs, the speed of coming up with new ideas, design, versions have increased

- Extensive field testing is not viable anymore

- Over the years, lots of digital footprint data of earlier design and earlier products have been accumulated and is available to serve as feed for AI ML

- Feel attribute is getting a lot of importance which results in the implantation of AI ML

Application of AI ML in Engineering Problems

Although Artificial Intelligence has found its niche in the engineering sector, it is extensively found in four areas of operation, which have a massive importance in today’s market.

Generative Design

As the related data are available for every product released in the market, we have a readily available vast database to quickly conjure up past information and generate engineering data out of it. This makes the task more streamlined, so we can understand product requirements, highlight the recurrence of similar conditions in the past, and pull out past data that have previously catered to the same.

This minimizes the time required to draw out an elaborate plan from scratch. If a problem is repetitive, it can be solved with the help of past data. This helps to intend to multiple issues simultaneously.

Failure Analysis

Failure Analysis is the collection of data and analysis to obtain the cause of a failure.

Failure analysis is essential as it helps pinpoint the causes, reasons behind causes and pave a way to determine corrective actions or liabilities. A massive set of failure analysis records is fed to AI ML, which comes in handy during similar failures. AI ML can assess the loss and come back with valuable information, should the incident occurred in the past. Once again, it reduces detailed investigation and time.

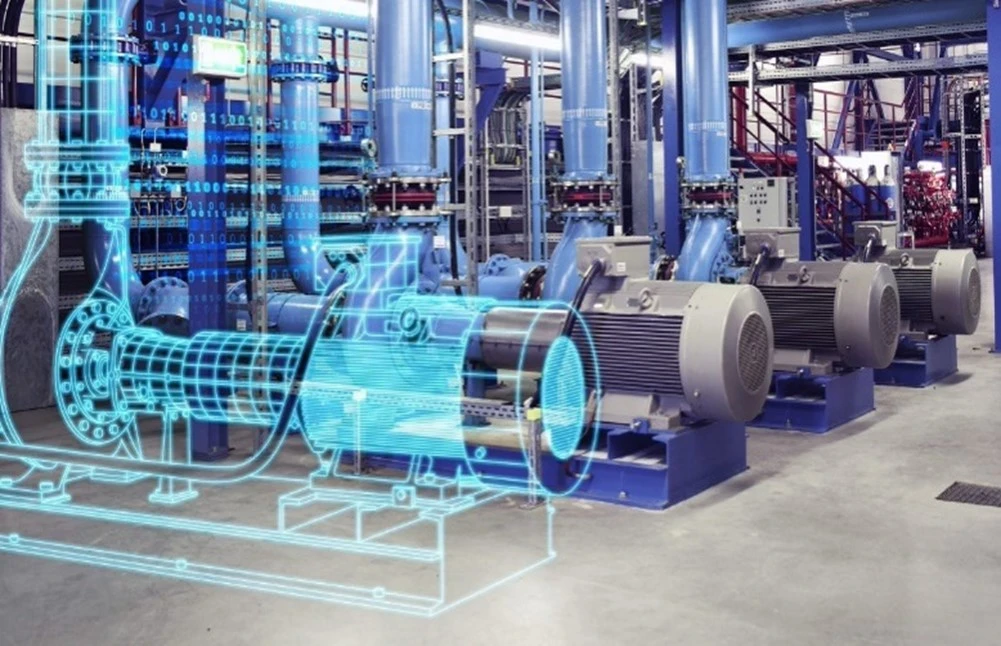

Digital Twins

A significant aspect of AI, while digital twin has been around circa 2002, credit goes to the Internet of Things (IoT) for making it cost-effective to implement. It was named one of the top 10 technology trends for 2017, considering it is imperative to business.

The digital twin is a virtual, digital replica of a real-world entity or process.

The intelligent components are integrated into a physical element to gather data such as working conditions, position, and process changes. The compiled data is collected, synthesized, and integrated into a virtual model and AI algorithms. Such data assets can be created even before the physical model is built. Applying analytics into these virtual models can give back relevant insights about the real-world asset. The best part of the digital twin is that once the physical and the virtual models are integrated, the virtual model can sync with the actual model.

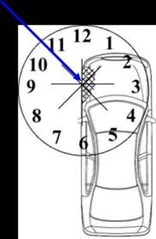

Digital Inspection

The digital inspection involves collecting information and analysis of products on production to ensure quality control.

The operation of digital inspection has gained considerable momentum in engineering, especially in the manufacturing sector. Unlike paper inspections which could have been laced with occasional errors, digital inspection minimizes or completely obliterates the chances of mistakes. AI ML has made its way to production and manufacturing, consequently providing automation that is faster, cost-effective, and superior to human involvement. AI-infused digital inspections build intelligent systems that perform quality checks down to the finest of details, leaving no stones unturned.

The rise of artificial intelligence has allowed automated machines to develop complicated manufacturing and design operations. AI has found significant importance in:

- Areas where data is available (or could be generated) and forward model is hazy or too complex

- Areas concerning partial data and incrementally growing data problems

- Areas of operation with disparate sources of information and varied data

- Forward engineering problems where constraints and inputs are not well defined/quantifie

The end goal is to introduce machines capable of learning, exploring, probing, and improving without human intervention. AI ML and Big Data are climbing the ladders of engineering with pace. An interesting point to bring up is that in our pursuit of creating supreme AIs, we are unwrapping information about how human brains perceive & operate and how we address the learning process, both consciously and unconsciously.