Evaluating ROI: Measuring the Impact of Additive Manufacturing Implementation

- Home

- Blog Details

- July 14 2023

- admin

Table of content

Introduction

Understanding Additive Manufacturing

- Cost Analysis

- Operational Efficiency

- Design Optimization

- Customization and Personalization

- Supply Chain Optimization

- Risk Management

- Quantitative and Qualitative Factors

- Market Expansion and New Business Opportunities

Challenges and Considerations in Additive Manufacturing Implementation

- Annotated Training Data

- Model Selection and Fine-tuning

- Computational Resources

- Generalization and Robustness

Future Trends and the Evolving Landscape of Additive Manufacturing ROI

Conclusion

Introduction

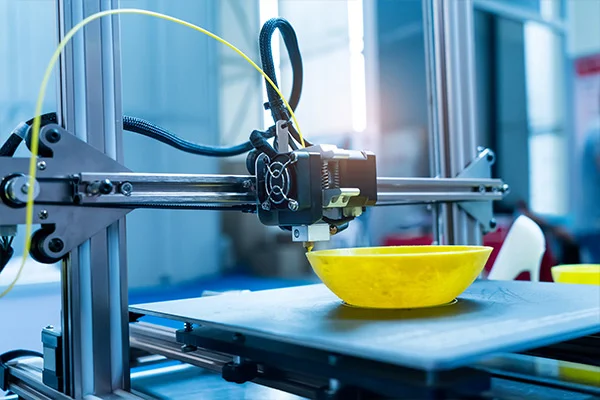

The ability to produce complicated parts with remarkable speed and efficiency thanks to additive manufacturing, often known as 3D printing, has completely changed the industrial sector. Businesses are becoming more concerned with assessing the return on investment (ROI) related to using additive manufacturing solutions as the technology develops and becomes more widely used.

This article looks at several aspects of additive manufacturing implementation and how organizations may evaluate their ROI effectively.

Understanding Additive Manufacturing

Additive manufacturing is a process that builds three-dimensional objects by adding successive layers of material based on a digital model. This technology offers numerous advantages over traditional manufacturing methods, including reduced lead times, lower costs, design flexibility, and the ability to produce complex geometries.

These benefits have attracted a wide range of industries, including aerospace, automotive, healthcare, and consumer products, to incorporate additive manufacturing into their operations.

Measuring ROI in Additive Manufacturing

Assessing the costs, advantages, and dangers of implementing additive manufacturing is necessary to calculate the return on investment. When assessing the effects of additive manufacturing on your company, keep the following points in mind:

Cost Analysis

Begin by analyzing the costs associated with implementing additive manufacturing. This includes the cost of acquiring 3D printers, software, materials, and training. Additionally, consider the costs of maintaining and operating the equipment, as well as any required facility modifications. You can estimate the financial impact by comparing these costs with the potential savings due to additive manufacturing.

Operational Efficiency

Additive manufacturing can considerably increase operational efficiency because lead times are shortened and supply chains are made simpler. Analyze the potential for time and money savings in your production processes by using additive manufacturing. One method to save assembly stages and material waste is to combine several pieces into a single 3D-printed component.

Design Optimization

Another key advantage of additive manufacturing is design flexibility. Traditional manufacturing methods often have limitations on complex geometries, but additive manufacturing allows for intricate designs with minimal constraints. Assess how this design freedom can enhance product performance, reduce material usage, and enable innovation. Consider the potential cost savings and revenue generation resulting from optimized designs.

Additive manufacturing enables customization and personalization at scale. Evaluate the market demand for customized products and assess how additive manufacturing can help meet these requirements. Customized products often command higher prices, leading to increased revenue potential.

Due to its ability to support decentralized production and on-demand manufacturing, additive manufacturing has the potential to upend conventional supply chains. Consider the effects of localized manufacturing, lower transportation costs, and advantages of inventory management. Take into account the potential reduction in lead times and the capacity to react swiftly to demand fluctuations.

Like any investment, additive manufacturing comes with inherent risks. Evaluate the potential risks associated with implementing the technology, such as operational challenges, quality control, intellectual property concerns, and regulatory compliance. Mitigate these risks by developing robust strategies and considering them in your ROI calculations.

Take into account both quantitative and qualitative considerations when assessing the ROI of additive manufacturing. Cost reductions, income growth, increased productivity, and less waste are examples of quantitative metrics. Improved consumer happiness, increased market competition, and the capacity to develop novel products are examples of qualitative metrics.

Market Expansion and New Business Opportunities

Additive manufacturing opens up new business opportunities and market expansion possibilities. Evaluate how implementing this technology can allow you to enter new markets, cater to niche customer segments, or offer unique products and services. Consider the potential revenue growth from tapping into previously unexplored markets or creating innovative business models based on additive manufacturing capabilities.

Challenges and Considerations in Additive Manufacturing Implementation

There are certain difficulties and things to think about in additive manufacturing implementation. Despite the fact that the technology has many advantages, businesses should be aware of any obstacles that could reduce the overall return on investment. Consider the following major difficulties:

The initial investment required for additive manufacturing implementation can be substantial. Organizations need to assess their financial capabilities and determine if they have the necessary budget to acquire the equipment, software, and training required for successful implementation. Conduct a thorough cost analysis and consider alternative financing options if needed.

Additive manufacturing relies on various materials, each with its own unique properties. Organizations must carefully evaluate material options to ensure they are suitable for the intended applications. Maintaining consistent quality control throughout the additive manufacturing process is crucial to avoid defects or deviations in the final products.

Additive manufacturing involves the use of digital models and designs, which can be susceptible to intellectual property theft or unauthorized replication. Organizations must implement robust security measures to protect their intellectual property and ensure data integrity throughout the additive manufacturing workflow.

Future Trends and the Evolving Landscape of Additive Manufacturing ROI

As additive manufacturing continues to evolve, several future trends will shape the ROI landscape. Understanding these trends can help organizations assess the long-term impact of additive manufacturing implementation. Here are some noteworthy trends:

- Hybrid Manufacturing

- Integrating additive manufacturing with traditional methods, known as hybrid manufacturing, offers unique advantages. Combining additive manufacturing’s design flexibility and customization capabilities with the efficiency and scalability of traditional manufacturing techniques can provide a higher ROI for certain applications.

- Industrialization of Additive Manufacturing

- Prototyping and low-volume production in additive manufacturing are giving way to full-scale industrialization. Organizations can boost ROI through high-volume manufacturing runs, lower costs, and increased efficiency as the technology develops and becomes more dependable.

- Digitization and Connectivity

- Digital technologies like artificial intelligence, machine learning, and the Internet of Things (IoT) are increasingly integrating with additive manufacturing. Real-time monitoring, predictive upkeep, and data-driven optimization are made possible by these developments, which boost ROI and operational effectiveness.

Conclusion

As additive manufacturing continues to reshape the manufacturing landscape, evaluating the ROI of additive manufacturing implementation is crucial for organizations considering adopting this technology. It involves considering the challenges and considerations, examining real-world case studies, and understanding future trends in the additive manufacturing landscape.

By carefully assessing the costs, benefits, and risks associated with additive manufacturing implementation, organizations can make informed decisions that maximize the ROI and leverage the full potential of this transformative technology. With ongoing advancements and increasing adoption, additive manufacturing will continue to reshape industries, drive innovation, and deliver substantial returns for forward-thinking organizations.

Interested in transforming your manufacturing processes? Discover the impact of additive manufacturing implementation on your business. Evaluate ROI, explore case studies, and stay ahead of the evolving landscape. Embrace the future of manufacturing with Prescient and take the first step today.