How Artificial Intelligence and 3D Printing can collaborate

- Home

- Blog Details

- April 9 2022

- admin

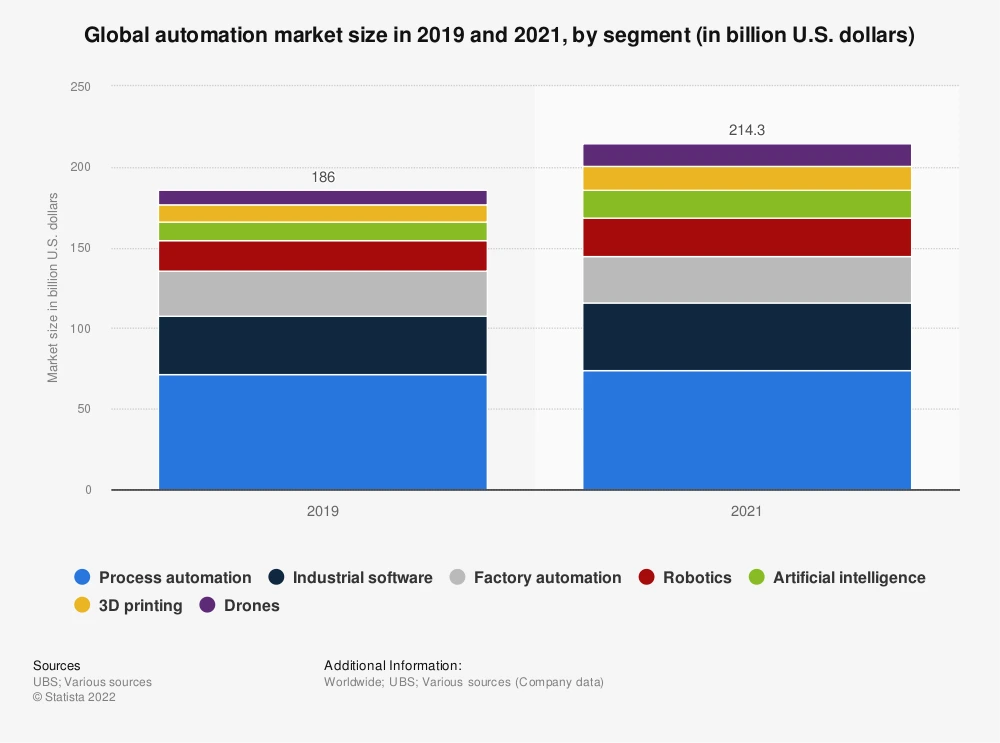

AI and 3D printing has been a hot tech for sometime and ever since their inception, these two domains has climbed steadfastly on the global market ladder. The 2019-20 global automation market size has displayed this rise. It is obvious that these two domain would cross paths sometime and strike up a beneficial collaboration.

The intersection of AI and 3D printing has long been predicted. AI can analyze a 3D model and determine which parts will fail to form the part. 3D printers can also remove material from failed regions and use AI to create a different version. AI can even analyze a part’s geometry and identify a potential problem so an alternative way to create it can be found. The end result? A better-designed part with a high rate of success.

Artificial Intelligence

The merging of artificial intelligence and 3D printing is an evolution of manufacturing paradigms. Prosthetics design, for instance, is one of the most important applications of 3D printing. As technology advances, artificial intelligence and 3D printers can be used to control 3D printers and increase the number of compatible materials for the process. By combining these two technologies, manufacturers can create new and improved products and production processes. Artificial intelligence and 3D printing will eventually help humans create better prosthetics.

The advancement of 3D printing has made it possible to create complex objects without the need for a human. Despite the complexity of the manufacturing process, AI can help to improve the process. The combination of AI and 3D printers will also create new applications. Here are some applications that will benefit from the convergence of these technologies. Once this technology becomes more widespread, it will revolutionize the manufacturing industry. It could even be used to create new prosthetic limbs that can be used for surgery.

3D Printing

AI and 3D printing are often associated, but it can also be used to create better products and objects. By automating processes, AI can help eliminate human error and enhance 3D printing performance. The fusion of AI and 3D printing has a number of benefits for manufacturing and quality control. It also helps accelerate the rise of Industry 4.0 and the Industrial Internet of Things. But which use cases will AI have in manufacturing? What are some examples of where AI is already being applied to 3D printing?

Machine learning, or AI, is a technology that can analyze a data stream and find hidden relationships. For instance, in the 3D printing process, artificial intelligence helps maintain the material properties of complex alloys, such as titanium, carbon, and other metals. The resulting models can be used for predictive maintenance. Machine learning can even help manufacturers improve spare parts and predict when to replace them. This is an exciting development for manufacturers and researchers alike.

Machine Learning

Bioprinting, also known as 3D bioprinting, is an emerging field in which machine learning is being used to improve the process of making organoids. This technique involves constructing a scaffold with a specific design to support cell growth and function. The complexity of the scaffold can have a big impact on the printed organ’s function. For this reason, scaffolds should be designed carefully and precisely to optimize the process.

Using machine learning in 3-D bioprinting can help detect defects, such as incorrectly positioned cells, curved layers, and microstructure errors. It can also monitor the entire bioprinting process and identify problems before they arise. One such example is shown in Figure 4, which uses CNN to detect defects during the bioprinting process. In this example, images from high-quality cameras during the bioprinting process are input data for the CNN, which analyzes the images to determine whether they are defects.

Applications of AI in 3D printing

AI has a number of advantages when it comes to 3D printing, including the ability to analyze an object before starting the process, and to predict the quality of the part. The use of machine learning algorithms also improves the fixation process and reduces manufacturing waste. Some projects are even aiming for zero-waste additive manufacturing. AI can also be used to protect important data about the printing process, such as reducing the number of errors.

A recent example of an application of machine learning in 3D printing is automated monitoring of 3D printed parts. By integrating image processing and camera data, supervised machine learning algorithms can detect defects during the printing process and help companies fix them without human intervention. The technology can also help companies cut the cost of reprinting parts if they have to fix a problem. Another cost-saving application of artificial intelligence in 3D printing is the guarantee of high- precision prints. A project developed by the University of Southern California has been designed to ensure that parts produced by 3D printing processes meet high-quality standards.

The possibilities for AI and 3D printing to collaborate are endless. We’ve seen how they can work together to create a prosthetic hand, and we believe that as these technologies continue to develop, the potential value they can provide each other will only increase.