How Inspection And Validation Can Improve The Reliability Of Additive Manufacturing Processes

- Home

- Blog Details

- March 27 2023

- admin

Table of content

What Is Meant by Inspection and Validation?

4 Steps to improve Inspection and Validation

- 1. Catching Errors Early

- 2. Ensuring consistent quality

- 3. Identifying areas for improvement

- 4. Increasing Confidence in the Final Product)

How Can You Implement Inspection and Validation in Your Additive Manufacturing Process?

Conclusion

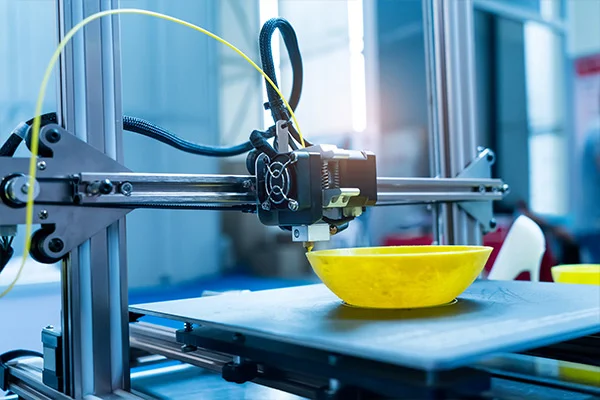

Do you want to make the processes you use for additive manufacturing more reliable? If so, you’ve come to the right place. This article will talk about how you can make your 3D printing more reliable by using inspection and validation.

The additive manufacturing method, which is sometimes called “3D printing,” is a business that is growing quickly and changing the way we make things. 3D printing is a popular way to make prototypes and custom parts because it can make complicated shapes and patterns. Still, as with any manufacturing process, it’s essential to make sure that the final product meets quality and reliability standards. At this point, there needs to be an inspection and validation.

What Is Meant by Inspection and Validation?

During the inspection, the printed item is looked at to make sure it meets certain standards, such as size, finish, and material quality. Validation, on the other hand, is the process of testing the part to make sure it works as expected under different conditions, like stress or heat.

Additive manufacturing might be more reliable if there were better ways to inspect and test products.

4 Steps to improve Inspection and Validation

1. Catching Errors Early

Inspection is a key part of the process of additive manufacturing because it lets you find mistakes early on. This is important because it could save you money and time in the long run. For instance, if a part is printed in the wrong size, it may be caught early and fixed so that the whole part doesn’t have to be made again or thrown away. If you catch problems early, you may save money and improve the overall quality of your printed parts.

2. Ensuring consistent quality

Checking and validating processes make sure that the quality of your printed parts is always good. This is very important if you want to make consistent products that meet your customers’ needs. By regularly testing and certifying your parts, you can find any quality problems and fix them before they get worse. This could make your customers happy and improve the quality of your goods as a whole.

3. Identifying areas for improvement

By looking at and testing your additive manufacturing process, you may find ways to make it better. For example, if parts keep failing a certain validation test, you can find out why and make any changes to the printing process that are needed. This could help you improve the performance and dependability of your printed parts, making your customers happier and making your goods work better overall.

4. Increasing Confidence in the Final Product

If you use inspection and validation techniques, you might be able to trust the end results more. This is very crucial in fields like medicine and aviation, where dependability is significant. Testing and validation make sure that your products meet the right standards and specifications and work as expected in different situations. This could help you meet client needs, get industry certifications, and build a stronger reputation as a reliable provider.

How Can You Implement Inspection and Validation in Your Additive Manufacturing Process?

1. Develop a Quality Control Plan

For your additive manufacturing process to work, you need a quality control plan that includes inspection and validation steps. This plan should say what will be checked and how validation tests will be done. The strategy should also say how much error is okay for each of the specs that are being tested. A good plan for quality control can help make sure that everyone who works on the part knows what it is supposed to do.

2. Invest in the Right Equipment

For inspection and validation procedures to work, you need to buy the right tools. Measurement tools, test equipment, and software are all examples of this type of equipment. You should choose the equipment based on how your production process works and how precise it needs to be. For example, you might need to buy a coordinate measurement machine (CMM) if you need to figure out the size of something.

3. Train Your Team

It’s necessary to show your staff how to use the equipment and go through the same inspection and validation steps every time. During this training, the contents of the quality control plan, the tools and equipment that are used, and the right way to do inspections and validation tests should all be talked about. The training should also cover what to do if a part doesn’t meet the requirements, such as writing down the problem and fixing it.

Conclusion

Inspection and validation are two important steps that help make additive manufacturing more reliable. You can make 3D printing more reliable by catching mistakes early, making sure the quality is always the same, looking for ways to improve, and having more faith in the end result. Do you want to use additive manufacturing more effectively? Prescient Technologies can assist you! Our software development services could completely change how you use 3D printing and other methods of “additive manufacturing.”

So, make a plan for quality control, get the right tools, and train your staff. Then, you’ll be on your way to better 3D-printed products.

References:

- adminhttps://www.pre-scient.com/author/webwideit/

- adminhttps://www.pre-scient.com/author/webwideit/

- adminhttps://www.pre-scient.com/author/webwideit/

- adminhttps://www.pre-scient.com/author/webwideit/