Remote Machine Monitoring System

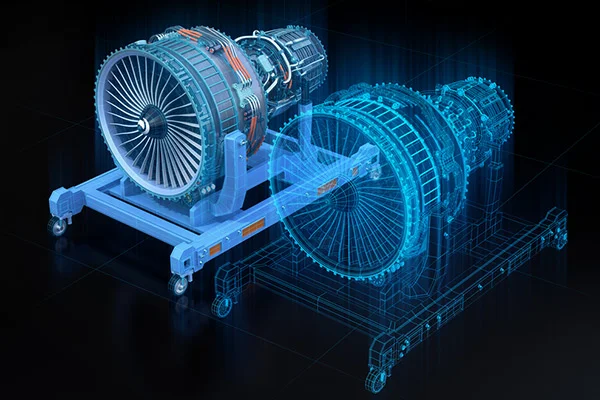

Smart Machine Monitoring System

machineCONNECT is an advanced after-sales intelligent monitoring system designed to help manufacturers monitor their machines from a command center for any faults and performance issues. This innovative solution combines cutting-edge technology with seamless integration to provide a comprehensive machine monitoring experience.

machineCONNECT helps you leverage the power of IIoT for your machines. It brings critical data from your machines in the field at your fingertips, in your own command center. It allows you to monitor and manage your machines anywhere in the world taking your commitment to your customers to the next level.

Key Features

Real-time Monitoring

machineCONNECT enables manufacturers to monitor their machines in real-time, allowing them to quickly identify and address any issues that may arise.

Fault Detection

The system is designed to detect even the slightest faults in the machines, ensuring that manufacturers can take prompt action to prevent downtime and maintain optimal performance.

Performance Analysis

machineCONNECT provides in-depth performance analysis, helping manufacturers to optimize their machines and improve overall efficiency.

Integration

This intelligent monitoring system seamlessly integrates with existing machine control systems, ensuring a smooth transition and minimal disruption to daily operations.

Scalability

machineCONNECT is designed to grow with your business, making it an ideal choice for manufacturers looking to expand their machine monitoring capabilities.

Featured Services

Benefits

Real-time Monitoring

The system enables real-time monitoring of machines, allowing for quick identification and resolution of issues.

Performance Tracking

machineCONNECT provides in-depth performance analysis, helping manufacturers optimize their machines and improve overall efficiency.

Predictive Maintenance

By detecting potential faults early, the system supports predictive maintenance, reducing downtime and maintenance costs.

Remote Diagnostic

machineCONNECT allows for remote diagnostic capabilities, enabling timely issue resolution and decreased downtime.

Empower Your Operations! Get in Touch Today for machineCONNECT.

Why Choose MachineCONNECT?

Cutting-Edge Technology for Real-Time Insights

machineCONNECT leverages the power of the Industrial Internet of Things (IIoT) to provide real-time monitoring of your machines.

Cost Savings

machineCONNECT saves costs through predictive maintenance, real-time monitoring, and performance tracking. Reduce downtime, optimize maintenance, and enhance efficiency for a stronger bottom line.

Fault Detection Excellence

machineCONNECT's system excels in detecting the most minute faults in your machines. With precision engineering, we empower you to take immediate action, prevent downtime, and maintain optimal performance seamlessly.

Optimize Efficiency with Predictive Maintenance

machineCONNECT goes beyond basic monitoring, providing manufacturers with tools for in-depth performance analysis. Optimize machine performance for improved efficiency and output.

What is machineCONNECT?

machineCONNECT is an after-sales intelligent monitoring system that enables manufacturers to monitor their machines in real time, detect faults, track performance, and facilitate predictive maintenance.

How does machineCONNECT benefit manufacturers?

machineCONNECT offers various benefits, including real-time monitoring, performance tracking, predictive maintenance, remote diagnostic capabilities, and valuable inputs for research and development.

Can machineCONNECT be integrated with existing machine control systems?

Yes, machineCONNECT is designed to seamlessly integrate with existing machine control systems, ensuring a smooth transition and minimal disruption to daily operations.

How does machineCONNECT contribute to cost savings?

By enabling predictive maintenance, real-time monitoring, and performance tracking, machineCONNECT helps manufacturers reduce downtime, optimize maintenance schedules, and improve overall efficiency, leading to cost savings.

Is machineCONNECT scalable for growing businesses?

Yes, machineCONNECT is designed to be scalable, making it an ideal choice for manufacturers looking to expand their machine monitoring capabilities as their business grows.

How does machineCONNECT ensure data security?

machineCONNECT prioritizes data security and utilizes industry-standard encryption and security protocols to ensure that the monitored data is protected and only accessible to authorized personnel.

What kind of support is available for machineCONNECT users?

machineCONNECT users have access to comprehensive technical support and training to ensure they can maximize the benefits of the system and address any issues that may arise.

Can machineCONNECT be customized to specific manufacturing needs?

Yes, machineCONNECT can be customized to meet the specific monitoring and reporting needs of different manufacturing environments, ensuring that it provides tailored and actionable insights for each user.