Improving Operational Efficiency with MES: A Deep Dive into its Benefits

- Home

- Blog Details

- September 8 2023

- admin

Operational effectiveness is crucial for companies trying to stay ahead in today’s cutthroat manufacturing environment. Manufacturing Execution Systems (MES) have changed the game by allowing producers to enhance production, streamline operations, and increase efficiency.

This article thoroughly explores MES and explains how it can increase operational effectiveness in an organization.

Manufacturers can use the power of MES to drive radical changes in their production processes by identifying and acknowledging the benefits of its implementation.

Real-Time Visibility and Control

The real-time visibility that MES gives manufacturers into their production activities enables them to monitor and manage every part of the manufacturing process. MES provides thorough insights into production indicators, machine status, work order progress, and resource use by combining data from numerous sources. This real-time visibility empowers firms to address bottlenecks, reduce downtime, and improve resource allocation. It also speeds up reaction times.

Furthermore, MES facilitates centralized control over production processes, enabling manufacturers to standardize workflows, enforce best practices, and implement consistent procedures across multiple production lines or locations. By providing a unified view of operations, MES enables organizations to identify inefficiencies, streamline processes, and ensure adherence to quality standards and compliance requirements.

Enhanced Production Planning and Scheduling

Manufacturing Execution Systems (MES) enable enterprises to optimize their production processes, save lead times, and boost overall efficiency, revolutionizing production planning and scheduling. Resource allocation, capacity planning, and workload balancing are made possible by MES’s extensive features.

By integrating real-time data on machine availability, labor capacity, and material availability, MES enables accurate production planning and scheduling. Manufacturers can optimize machine utilization, reduce idle time, and minimize changeover times, leading to increased throughput and reduced production cycle times.

Additionally, MES enables dynamic rescheduling to accommodate unforeseen changes, such as rush orders or machine breakdowns, ensuring optimal production efficiency.

Improved Quality Control and Traceability

MES plays a pivotal role in improving quality control processes and ensuring product traceability throughout the manufacturing lifecycle. By capturing real-time data at every stage of production, MES enables manufacturers to monitor and control quality parameters, perform inspections, and enforce adherence to quality standards.

Manufacturers can use automated data gathering and analysis using MES to spot and fix quality problems instantly. MES provides a framework for Statistical Process Control (SPC), allowing producers to track quality metrics, spot deviations, and quickly take corrective action. MES-driven quality control measures allow manufacturers to lower the amount of scrap, rework, and defects, improving product quality and customer satisfaction.

By recording and storing complete data on materials, components, processes, and related data, MES also makes thorough product traceability possible. Manufacturers can swiftly pinpoint the underlying cause of a quality problem or product recall, carry out focused corrective actions, and lower the adverse impact on customers and brand reputation.

Streamlined Inventory Management

Manufacturers can optimize inventory levels, lower carrying costs, and enhance supply chain performance, thanks to MES’ all-inclusive inventory management solution. MES offers precise visibility into inventory levels, consumption rates, and material requirements through real-time data integration and analysis.

By synchronizing production schedules, material availability, and customer demand, MES enables manufacturers to minimize stockouts and excess inventory. With accurate demand forecasting and just-in-time inventory management, manufacturers can achieve better inventory accuracy, reduce carrying costs, and optimize working capital.

The automation of material replenishment procedures, the provision of real-time inventory updates, and the facilitation of seamless coordination between production, procurement, and warehousing operations are ways in which MES facilitates effective material flow and control. As a result, supply chain activities are streamlined, delays are reduced, and materials are always available at the appropriate time and in the appropriate quantity.

Data-Driven Decision Making and Continuous Improvement

Manufacturers who use MES have access to data-driven decision-making skills, allowing them to take advantage of insights and promote efforts for continuous improvement. Massive volumes of real-time production data are collected and analyzed by MES, which offers actionable insights that support well-informed decision-making.

Manufacturers can spot trends, patterns, and performance measures that affect operational effectiveness through comprehensive analytics and reporting features. Key Performance Indicators (KPIs) and customizable dashboards provided by MES enable businesses to track several metrics, including Overall Equipment Efficiency (OEE), production yield, downtime, and quality. With the use of such data, manufacturers can highlight areas for improvement, focus on bettering them, and assess the results of changing their processes.

MES also supports the deployment of continuous improvement processes such as Lean and Six Sigma. It allows firms to discover waste, variability, and non-value-added operations by offering real-time visibility into processes. This enables manufacturers to implement lean principles, promote process optimization, and foster a culture of continuous improvement throughout the firm.

Enhanced Compliance and Regulatory Compliance

Manufacturing Execution Systems (MES) implementation improves adherence to industry norms and regulations, ensuring that manufacturers fulfill the necessary criteria and uphold regulatory compliance.

For maintaining and enforcing compliance with industry-specific rules like Good Manufacturing Practices (GMP), ISO standards, and certain quality certifications, MES offers a consolidated platform. Manufacturing Execution Systems (MES) ensure that manufacturers follow the appropriate regulations and maintain consistent compliance throughout their operations by combining quality control processes, documentation management, and audit trails.

With MES, manufacturers can capture and store critical data related to production processes, materials, and quality control parameters. This data is readily available for audits, inspections, and regulatory reporting, ensuring transparency and accountability. MES facilitates efficient documentation management, automating the generation and storage of critical documents, including batch records, Standard Operating Procedures (SOPs), and quality control documentation.

Conclusion

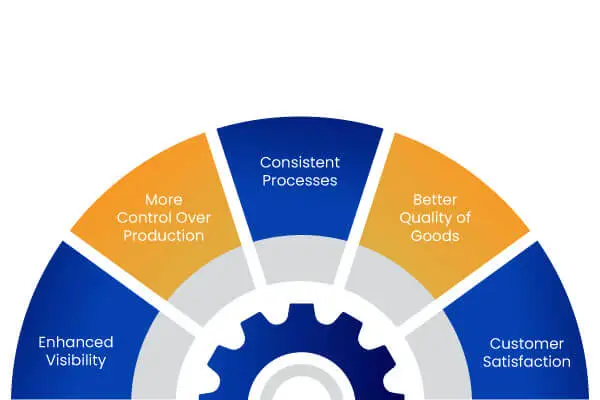

Manufacturing Execution Systems (MES) provide businesses with a variety of advantages targeted at enhancing operational effectiveness. Through increased production planning, quality control, inventory management, data-driven decision-making, compliance management and real-time visibility and control, MES helps businesses streamline their operations, cut costs, and promote continuous development.

Manufacturers can obtain a competitive edge in the dynamic production environment by deploying MES. Organizations can make data-driven choices, react swiftly to changes, and adhere to regulations, thanks to the comprehensive functions of MES. Manufacturers may streamline operations, boost productivity, provide high-quality goods, and maintain compliance with industry norms and laws using MES as a fundamental technology.

Adopting MES becomes a strategic necessity as manufacturers look for ways to increase their operational efficiency. They may flourish in a market that is changing quickly, exceed customer expectations, and achieve sustainable growth through MES. Adopting MES is a crucial step to modernizing production processes, releasing untapped potential, and maintaining a leading position in the manufacturing sector.

Ready to improve your operational efficiency and unlock the full potential of Manufacturing Execution Systems (MES)? Partner with Prescient to revolutionize your production processes. Contact us today to discover how Prescient can drive efficiency, quality, and compliance in your manufacturing operations.