CAx Software for Simulation and Analysis: Integrating Engineering Tools

- Home

- Blog Details

- July 14 2023

- admin

Table of content

Introduction

The Need for Simulation and Analysis in Engineering

CAx Software: A Platform for Integration

Benefits of Integrating Engineering Tools with CAx Software

- Enhanced Design Iteration

- Improved Design Optimization

- Accurate Performance Prediction

- Seamless Data Exchange

Challenges in Integrating Engineering Tools with CAx Software

Emerging Trends in CAx Software Integration

Conclusion

Introduction

Computer-aided design software has transformed engineering by speeding up the design process and allowing engineers to generate complicated models quickly. However, CAx has capabilities that go beyond design. Engineers can use CAx software for simulation and analysis to study the behavior and performance of designs before manufacturing.

This article examines how engineering tools can be integrated with CAx software, highlighting the advantages, difficulties, and new developments.

The Need for Simulation and Analysis in Engineering

Analysis and simulation are essential components of the engineering design process. They enable engineers to assess numerous design options, spot potential issues, and enhance performance. Engineers can evaluate structural integrity, fluid movement, heat transfer, and electrical behavior. Engineers may improve the overall quality of their designs, lower costs, increase efficiency and make informed decisions.

CAx Software: A Platform for Integration

CAx software is an ideal platform for integrating simulation and analysis tools. Its extensive capabilities enable widespread use in the engineering industry. Engineers can seamlessly transition from design to analysis without complex data transfers or software interoperability challenges. They can incorporate these tools directly into the CAx environment.

Benefits of Integrating Engineering Tools with CAx Software

There are several benefits to combining engineering tools with CAx software. These range from incredible teamwork and increased design effectiveness to cost and time savings. Let’s get started and discover how using CAx software and engineering tools may improve your designs:

Engineers can perform virtual tests and experiments by integrating simulation and analysis tools with CAx software, allowing rapid design iterations. They can quickly evaluate design changes, assess their impact, and refine their models accordingly. This iterative process significantly reduces physical prototyping and testing time and cost.

Engineers can more efficiently optimize their designs with CAx software for simulation and analysis tools. They can use cutting-edge algorithms and optimization approaches to alter design parameters for optimal performance automatically. The process is based on predetermined criteria. This integration allows engineers to explore various design options and quickly find the best solutions.

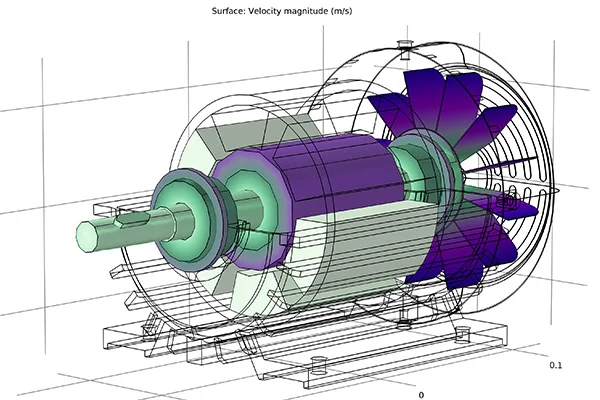

Simulation and analysis tools integrated into CAx software give engineers accurate predictions of a design’s behavior and performance. Engineers can assess stress distribution, thermal behavior, fluid dynamics, and electromagnetic properties by replicating real-world conditions. This knowledge helps engineers identify potential weaknesses and make necessary improvements before manufacturing, ensuring better overall performance and reliability.

Integrating CAx software for simulation and analysis tools ensures seamless data exchange between different engineering domains. Engineers can transfer design parameters, geometric information, and simulation results between various analysis modules within the CAx environment. This integration promotes collaboration, improves data consistency, and eliminates the need for manual data translation or re-entry, reducing the chances of errors.

Challenges in Integrating Engineering Tools with CAx Software

A unique set of difficulties arises while navigating the complex environment of CAx software integration with engineering equipment. Let’s look at some of the significant obstacles and possible solutions to get through them so that the integration process runs smoothly and successfully:

Integrating simulation and analysis tools within CAx software requires a complex software architecture that can handle the diverse requirements of different engineering domains. Software developers face significant challenges in ensuring smooth communication between CAx and analysis modules, data synchronization, and maintaining a user-friendly interface.

Different vendors often develop CAx software for simulation and analysis tools, resulting in interoperability challenges. Standardization efforts, such as the STEP (Standard for the Exchange of Product Data) format, have helped mitigate these issues. However, further collaboration and standardization initiatives are required to ensure seamless integration and data exchange between software tools.

Simulation and analysis processes can be computationally intensive, requiring substantial computational resources. Integrating these tools within CAx software necessitates optimizing performance, memory management, and scalability to efficiently handle large and complex models. This challenge becomes more significant as engineers demand faster simulations and analyses to meet tight project deadlines.

Emerging Trends in CAx Software Integration

CAx software integration is changing due to some intriguing new trends. These developments rethink how engineers approach design and analysis and present new opportunities. Let’s investigate the most recent developments that are elevating CAx software integration to new levels:

Cloud computing offers a promising solution for CAx software integration by providing scalable computational resources and collaborative environments. Cloud-based CAx platforms enable engineers to access simulation and analysis tools remotely. It reduces the burden on their local machines and facilitates real-time collaboration among team members.

CAx software’s inclusion of AI algorithms improves simulation and analysis capabilities. AI can optimize designs, automate complicated operations, and increase the precision of predictions. Machine learning approaches might advise design alterations based on simulation findings. Advanced technical analysis and optimization are now possible thanks to the combination of AI and CAx software.

Multi-disciplinary optimization features are being added to CAx software to address the increasing complexity of engineering systems. Engineers may optimize designs simultaneously for numerous domains because MDO integrates several analysis modules. Engineers may use this method to investigate intricate design spaces, weigh trade-offs between several disciplines, and produce comprehensive design solutions.

Conclusion

CAx software has significantly developed from a simple design tool to a complete simulation and analysis platform. Engineers can easily switch from design to analysis by integrating engineering tools into the CAx environment, streamlining the product development process. Enhanced design iteration, better optimization, precise performance forecasting, and seamless data interchange are some advantages of this connection.

However, issues with software architecture, interoperability, and computational needs must be resolved to fully utilize the potential of CAx software for simulation and analysis. The future of CAx software integration looks bright with growing trends, including cloud-based solutions, AI integration, and multi-disciplinary optimization, promising even better efficiency and innovation in engineering design.

With Prescient, you can harness the strength of integrated engineering tools. Make more educated judgments, increase performance, and streamline your design process. Increase the capabilities of your CAx software right away!