What are BREP and CSG | Difference between BREP and CSG

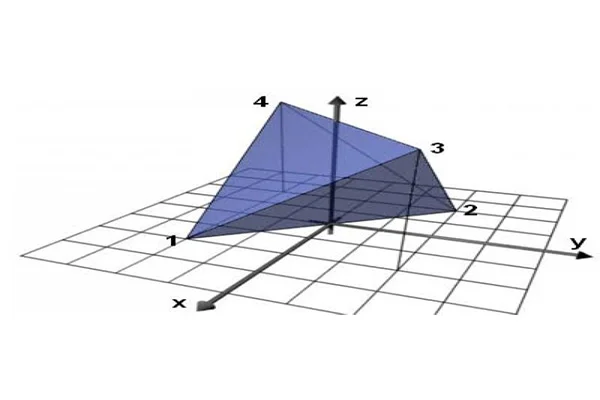

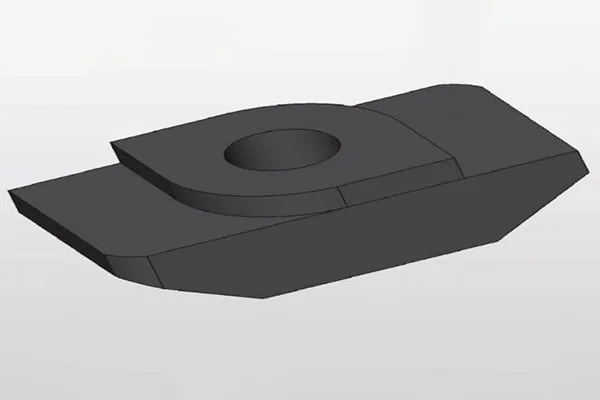

Table of Content Constructive Solid Geometry Boundary Representation Differences between BREP and CSG The geometric modeling technique has revolutionized the design and manufacture of products to a great extent. Although there have been various ways of representing an object, the most commonly used modeling technique is Solid Modelling. Boundary Representation modeling and Constructive Solid Geometry modeling are the two main ways to express solid models. Constructive Solid Geometry Constructive solid geometry or C-REP/CREP, previously known as computational binary solid geometry, is a reliable modeling technique that allows the creation of a complex object from simple primitives using Boolean operations. It is based on the fundamental that a physical object can be divided into a set of primitives or basic elements combined in a particular order by following a set of rules (Boolean operations) to create an object. Typically, they are objects of simple shapes such as cuboids, cylinders, prisms, pyramids, spheres, and cones. CSG cannot represent fillets, chamfers, and other context-based features. The primitives are considered valid CSG models, where each primitive is bounded by orientable surfaces (Half-spaces). These simple primitives are in generic form and must be confirmed by the user to be used in the design. The primitive may require scaling, translation, and rotation transformations to be assigned a coveted position. There are two kinds of CSG schemes: Primitive-based CSG: A popular CSG scheme based on bounded solid primitives, R-sets.Half-space-based CSG: This CSG scheme uses unbounded Half-spaces. Bounded solid primitives and their boundaries are considered composite half-spaces and the surfaces of the component half- spaces, respectively. Some attributes of CSG are as follows: Boundary Representation In solid modeling and computer-aided design, boundary representation or B-rep / BREP—is the process of representing shapes using the limits. Here a solid is described as a collection of connected surface elements. BREP was one of the first computer-generated representations to represent three- dimensional objects. BREP defines an object by its spatial boundaries. It details the points, edges, and surfaces of a volume. BREP can also be explained in terms of cell domain combination. A cell is a connected limitation of the underlying geometry. There are four kinds of cells as per the spatial dimension they inhabit: A domain is a set of connected cells grouped to define boundaries. Fields define various components inside a non-manifold object.Boundary representation of models consists of two kinds of information:Topology: The main topological entities are faces, edges, and vertices.Geometry: The main geometrical entities are surfaces, curves, and points. The topological and geometrical entities are intertwined in a way where: BREP comes with its share of advantages and disadvantages, which are: Differences between BREP and CSG Boundary Representation(BREP) Constructive Solid Geometry(CSG) BREP describes only the oriented surface of a solid as a data structure composed of vertices, edges, and faces. A solid is represented as a Boolean expression of primitive solid objects of a simpler structure. A BREP object is easily rendered on a graphic display system. A CSG object is always valid because its surface is closed and orientable and encloses a volume, provided the primitives are authentic in it. Basic operations include reviewing the possible surface types, the winged-edge representation schema, and the Euler operators for BREP. Basic operations include classifying points, curves, and surfaces concerning a solid, detecting redundancies in the representation, and approximating CSG objects systematically.

Read MoreFaceted Modeling and NURBS

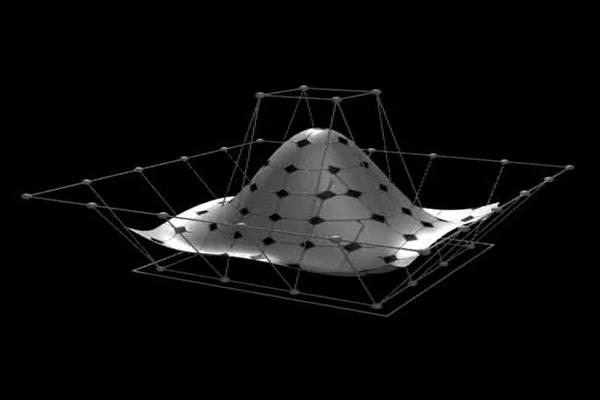

Modern CAD systems and CAD packages enable designers to model objects and retrieve them in their formats. Some formats are interchangeable while some enforce restrictions, upon which, it becomes difficult to transfer an object model from one form to another. This article describes some of the most used CAD formats in the industry. But before we look into various CAD formats, it is essential to understand the concept of Faceted geometry and Analytic geometry (NURBS). FACETED GEOMETRY Faceted geometry, also known as discrete geometry, are models which consist of groups of polygons which is often triangles. Most Computer-Aided Design (CAD) systems typically use continuous surface and edge definitions based on NURBS. CAE simulations break down this NURBS representation into facets by a process known as meshing. The faceted models are quite appealing to engineering marketing, as such simulations are less bothered with exact physical reality and tend to emphasize on creating eye-catching visuals, such as airflow over a car, which can be incorporated into a marketing brochure. File formats typically used for faceted models are: .3ds, .dxf, .obj, .stl (Stereolithography). Almost all the faceted formats, except for STL, reflect material properties such as glass and metal by providing groupings of facets. However, such groupings are inadequate for a CAE simulation. ANALYTIC GEOMETRY (NURBS) NURBS or Non-uniform rational basis spline describes curves and surfaces with mathematical functions, and form the most common analytic geometry representations. The NURBS geometry has unlimited resolution. The NURBS definition defines the location of the boundary points and uses control points with slope definition to determine the internal shape of curves and surfaces, thereby enabling a great deal of flexibility. NURBS geometry is typically produced in CAD systems such as CATIA, Pro/Engineer, Solidworks, NX, etc. A significant drawback of NURBS geometry is that they are generally specific to the CAD packages that created them, and interchanging formats can be error-prone and inaccurate. DIFFERENCE BETWEEN FACETED GEOMETRY AND ANALYTIC GEOMETRY (NURBS) Faceted geometry NURBS geometry Facets are always guaranteed to comply with the original definition In NURBS geometry, different levels of model detail are created without losing fidelity Faceted geometry describes a shape as a mesh, points usually connected by triangles Analytic geometry defines curves and surfaces with mathematical functions Faceted geometry has limited resolution NURBS geometry has unlimited resolution Evaluating a faceted surface, one can get a shape defined by linear interpolation between known discrete points One can assess a NURBS surface anywhere and get coordinates lying on the surface Simple definition Includes topology Cons of Faceted geometry Cons of NURBS geometry Fixed resolution More computing intense No topology High data exchange Although faceted geometry has its use, NURBS geometry is superior for design and manufacturing processes. Due to the high demands on geometric precision, NURBS geometry finds its place in CAE applications. But if the modeling requirements ask for stunning visuals, faceted models are worth giving a try.

Read MoreTypes of Geometric Modeling

Table of Content Solid Modeling Surface Modeling Wireframe Modeling The previous edition gave a brief introduction to Geometric Modeling and its features. Geometric modeling is the mathematical representation of an object’s geometry. It incorporates the use of curves to create models. It can be viewed either in 2D or 3D perspective. The general design is applied to different geometric structures, including sets and graphs. This article introduces geometric models which represent geometric objects and their properties mathematically. They can be viewed as collections of squares of different colors. On the other hand, geometric shapes can be considered mathematical equations. Geometric models can represent data in context, such as a digital image. Regardless of the modeling approach, all students should understand how CAD software works. A basic understanding of geometric modeling is essential for any aspiring designer. In contrast, button- push robots often neglect this aspect of CAD training. However, preparing students with the fundamental knowledge of geometric modeling is also critical for their competitive edge. This edition details the primary types of geometric modeling. Geometric modeling can be classified into the following: Solid Modeling Also known as volume modeling, this is the most widely used method, providing a complete description of solid modeling. Solid modeling defines an object by its nodes, edges, and surfaces; therefore, it gives a perfect and explicit mathematical representation of a precisely enclosed and filled volume. Solid modeling requires topology rules to guarantee that all covers are stitched together correctly. This geometry modeling procedure is based upon the “Half-Space” concept. A solid model begins with a solid, which is then stitched together using topology rules. Solid modeling has many benefits, including improved visualization and functional automation. CAD software can quickly calculate the actual geometry of complex shapes. A cube, for example, has six faces, a radius of 8.4 mm, and many radii. It has many angles and a shallow pyramid on each face. By applying solid modeling concepts, CAD programs can quickly calculate these attributes for a given cube. Similarly, a cube with rounded edges has many radii and faces. There are two prevalent ways of representing solid models:Constructive solid geometry: Constructive solid geometry combines primary solid objects (prism, cylinder, cone, sphere, etc.). These shapes are either added or deleted to form the final solid shape.Boundary representation: In boundary representation, an object’s definition is determined by its spatial boundaries. It describes the points, edges, and surfaces of a volume and issues the command to rotate and sweep bind facets into a third-dimensional solid. The union of these surfaces enables the formation of a surface that explicitly encloses a volume. Solid Modeling is the most widely used geometric modeling in three dimensions, and it serves the following purpose: Different solid modeling techniques are as follows: Surface Modeling Surface modeling represents the solid appearing object. Although it is a more complicated representation method than wireframe modeling, it is not as refined as solid modeling. Although surface and solid models look identical, the former cannot be sliced open the way solid models can be. This model makes use of B-splines and Bezier for controlling curves. When polygons or NURBS represent surfaces, the computer can convert the commands into mathematical models. These models are saved in files and can be opened for editing and analysis at any time. The process of importing models from other programs is often complex and problematic, resulting in ambiguous results. In contrast, surface modeling allows for precise changes to difficult surfaces. A typical surface modeling process involves the following steps: Surface modeling is used to: Geometric surface modeling has proven to be extremely useful in computer graphics. Multiresolution modeling involves the generation of various surfaces at different levels of detail and accuracy. The resulting surfaces are then applied to various problems, including general surface estimation from structured and unstructured data. One such application is a subdivision surface, which begins from a simple primitive and gradually adds tools and details. Wireframe Modeling A wireframe model is composed of points, lines, curves, and surfaces connected by point coordinates. Because the model is not solid, it is difficult to visualize, but it helps generate simple geometric shapes. The resulting model contains information on every object’s point, edge, face, and vertices. This model is beneficial for creating an orthographic isometric or perspective view. The lines within a wireframe connect to create polygons, such as triangles and rectangles, representing three-dimensional shapes when bound together. The outcome may range from a cube to a complex three-dimensional scene with people and objects. The number of polygons within a model indicates how detailed the wireframe 3D model is. Wireframe modeling helps in matching a 3D drawing model to its reference. Planar objects can be moved to a 3D location once they have been created. It allows the creator to match the vertex points to align with the desired reference and see the reference through the model. Although Wireframe modeling is a quick and easy way to demonstrate concepts, creating a fully detailed, precisely constructed model for an idea can be highly time-consuming. If it does not match what was visualized for the project, all that time and effort is wasted. In wireframe modeling, one can skip the detailed work and present a very skeletal framework that is simple to create and apprehensible to others. Using a wireframe model as a reference geometry will help you create a solid or surface model that follows a definite shape. In this way, you can easily visualize your model and select objects. The wireframe model is decomposed into a series of simple wireframes and the desired face topology.

Read MoreWhat is Geometric Modeling

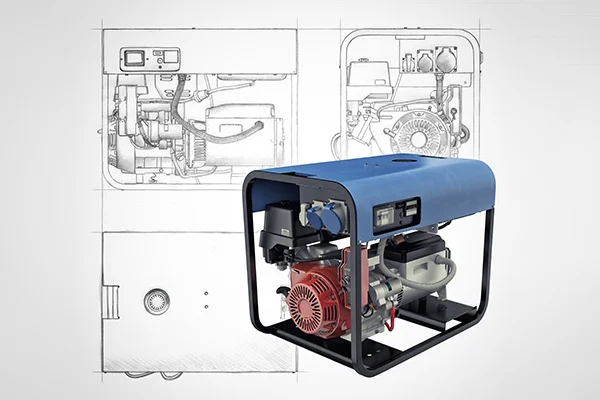

Table of Content Representation of Geometric Models Types of Geometric Modelings Requirements for Geometric Modeling The culture of design & manufacturing incorporates various crucial aspects for producing a market- efficient product. Computer-aided Engineering or CAE is a central part of the entire manufacturing process. Over the years, the function of CAE has evolved so much that it has developed its applications depending upon the type of usage and execution. Geometric Modeling happens to be one of the most popular CAE applications. Geometric Modeling is the computer/software-generated mathematical representation of an object’s geometry. It includes both graphical and non-graphical information. This information is stored in a database and displayed as a picture. It is then possible to edit and analyze the model in different ways. As curves are easy to manipulate and bend as per application, geometric modeling uses curves extensively to construct surfaces. The formation of curves can be achieved by – a set of points, analytic functions, or other curves/functions. The mathematical representation of an object can be displayed on a computer and used for the generation of drawings, which go on for analysis and eventual manufacturing of the object. In general, there are three conventional steps to creating a geometric model: Representation of Geometric Models There are two basic types of geometric models: a two-dimensional model, which is used for technical drawing, and a three-dimensional model, which is used for computer-aided design and manufacturing. Constructing a geometric model in CAD involves using a 3D computer program to describe geometric relationships and the physical extent of a component. The models may also contain material properties and other attributes of the element, such as the mass of the component. Many CAD programs can calculate a component’s mass properties and evaluate its other physical properties. These capabilities may be crucial for flexible and adaptive manufacturing lines. There are two main types of representations in geometric modeling. The classical presentation of geometric objects consists of geometric pointsets defined by boundaries. On the other hand, modern geometric modeling uses parametric families of pointsets. Parametric families are defined using geometric operation graphs, features, and constraints. In both cases, a user interacts with an example object from the family. It may also be a surface, a volume, or a solid. In addition to these models, geometric modeling can incorporate other design and manufacturing aspects. Computer- aided engineering, or CAE, is the central component of the manufacturing process. With the help of geometric modeling applications, key elements can be created, transformed, and integrated into the desired shape. In addition to this, CAD applications can also incorporate complex mathematical operations. Types of Geometric Modelings Depending upon the representations of objects, geometric modeling system can be classified into three categories, which are: Solid modelingSolid modeling also known as volume modeling, this is the most widely used method, providing a complete description of solid modeling. Solid modeling tools allow you to build many sides of an object at once. Solid models make multiple sides at once, reducing the ambiguity in surface modeling. Surface modelingSurface modeling is another popular method. This type of modeling represents the object by its surface and is used to describe the object with a clear view of manufacturing. This method uses surface geometry to create objects with complex forms. From this clear point of view, surface modeling cannot be used to develop an internal surface of any model. Surface modeling uses Bezier and B-spines. Surface modeling is better for design engineers as it organizes the edges that define polygonal surfaces. Wireframe modelingIt is a simple modeling system used to represent the object with the help of lines only. Hence, it is also known as Line model representation. However, wireframe modeling is not enough to express complex solids; therefore, it is used to describe only wiring systems. Wireframe geometric modeling is a good option for small-scale companies, where intricate surface details are essential for product design. Requirements for Geometric Modeling The various requirements of geometric modeling are as follows: Geometric modeling is a vast and elaborate field of CAE and requires in-depth study. The following articles dive deep into the various types and facets of geometric modeling.

Read More