Employee Engagement Kashmir – Jan 2019

Employee Engagement Kashmir – Jan 2019 Previous image Next image “Children are not things to be molded but people to be unfolded” – Jess Lair It is said and believed that children are the future of a nation. The examples we set today and the values we sow in them act as the principles which will run a healthy society in the future. Proper nurture and education have always made significant impacts on a child. Owing to the great cause and adhering to Corporate Social Responsibility (CSR), the Jammu & Kashmir Knowledge Network (JKKN) in association with Jnana Prabodhini, a Pune based organization; organized an online lecture with the help of an expert, Ms. Deepti Waghmare, Director – Legal, HR & Admin in Prescient Technologies Pune, for the students of Jammu and Kashmir on 17th January 2019. The Guest Speaker, who is also an alumnus of Jnana Prabodhini, spoke on the topic ‘CAREER IN LAW’. In her lecture, she guided the students about: • career options available after completing a Bachelor’s Degree in Law • getting enrolled in LLB after passing higher secondary (12th ) • clearing exam to get a license for practice as a lawyer in court • starting a law firm or work with a law firm • how law firms operate and the variety of services provided by the law firms • competing and cracking competitive exams to join in Judicial services as Judge Nearly 550 students of 12 schools from the Jammu Division participated in the online interaction. The session ended with Ms. Waghmare answering a number of questions raised by the participants in an enlightening and academic way. We at the Prescient family take pride in Ms. Deepti Waghmare and Jnana Prabodhini’s team for participating in such a noble cause and we are committed to working for the cause of children and the overall betterment of society.

Read MoreReverse Engineering: Outsourcing and Beyond

FAQs Points to keep in mind while outsourcing reverse engineering services Choosing a Vendor all know reverse engineering is an economical approach towards product development & innovation, which manufacturers often utilize to evaluate and redesign competitor products. Reverse Engineering services involve understanding the product design, system integrity, and manufacturing processes involved to realize the potential required to build a similar or improved product version. The reverse engineering technique is best suitable for producing design data and related technical manuals for products that no longer have any design information. The entire work process involves engineers studying every design feature, associated manufacturing processes, and tools needed for product development and storing information. After digitizing the complete information, suitable design modifications are carried out as per requirements. However, to get things right, one should have an efficient and dedicated engineering team, the right software, hardware tools, etc., which seems difficult to have within the organization. FAQs Here comes the advantage of outsourcing reverse engineering projects where the activities can significantly reduce the cost of product development and burden the engineers who can focus on developing innovative design solutions for the product.Reverse engineering services outsourcing might invoke some hesitancy. To address it, here are some of the crucial benefits of outsourcing reverse engineering projects: Still have more questions, ask us Prescient Technology’s reverse engineering expertise has helped companies meet their designing and innovative demands. If you wish to know more, just click the button below. Points to keep in mind while outsourcing reverse engineering services As feasible as reverse engineering outsourcing sounds, there are specific steps to follow and factors to consider. Few crucial points to discuss when outsourcing reverse engineering services are as follows: Choosing a Vendor After finalizing the decision to outsource reverse engineering service, the next vital step to consider is choosing a vendor. A responsive and efficient vendor makes all the difference. Finding a professional vendor with a high level of efficiency and even heightened work ethic is a complex but satisfying process. Be aware that once you are engaged with a vendor, it becomes a little difficult to break the deal and discontinue ‘business’ with the existing vendor. So choose carefully but commit completely after the contract.When a vendor has been finalized, the organization issues a request for quotation (RFQ). RFQs are created to invite suppliers to a bidding process to bid on specific services/products. The organization should also take a legal approach and have the service provider’s non-disclosure agreement (NDA). This is done to prevent unlawful, authorized distribution, or illicit product adoption.Now that the legal approach and paperwork have been taken care of, the organization sends the physical product to the service provider or the scanned files, depending on the company’s needs. The vendor is also supplied with measurement specifications and related industry standards to follow. Eventually, the vendor creates a digital format and sends it back to the organization for further design modification or innovation investigations.For manufacturers, reverse engineering is a profitable strategy in today’s competitive scenario; however, outsourcing brings along the other benefits that ensure the product development process remains cost-effective. Prescient Technologies is adept at providing outstanding reverse engineering services and has extensive experience in the end-to-end process, so feel free to contact us today.

Read MoreDigitization

For starters, digitization is converting of analog/physical things such as paper documents, microfilm images, photographs, sounds and more into digital (bits and bytes) version. So it is simply converting and/or representing something non-digital into a digital format which then can be used by a computing system for numerous reasons. Sometimes a paper document gets destroyed after having digitized, sometimes we capture the sound and images in the form of video of your presentation at an event, the digital format continues to exist while your voice and physical presentation during that presentation are gone forever. Digitizing doesn’t means replacing the original document, image, sound, etc. Another synonymous term is ‘Automation’ which more or less means the same. The conversion of physical data into intangible format has its benefit and has revolutionized paperwork in its own way. Benefits of Digitization 5 ways digitization is helping the business Automation/Artificial Intelligence There have been debates about automation and development of artificial intelligence (AI) over the last couple of years. All credits to movies and their takes on AI. Some eminent minds have also predicted its dark future. However, AI has already changed the business world with companies gradually automatizing work and other sorts of activities. Almost 85% of industry leaders believe automation will allow their companies to obtain or sustain a competitive advantage. Flexibility of working hours With all the data and information being stored on digital media and devices; digitization has made it possible for us to transform it and access it from anywhere. As a result, we can adjust our work schedule to our personal needs and lifestyle. We can choose how to work and when to work, and we owe it to digitization. Innovation We all know, innovation helps companies come up with groundbreaking ideas, use special tools and business applications for organizing & managing work, reach wider audience and create a better product. Digitization is not only about transforming physical data into digital format, but also about using it and finding new ways of developing/enhancing them. Communication The lack of right information transfer leads to misunderstandings and conflicts. Without proper communication, a business cannot thrive. Communication has always been one of the most important aspects of our lives. Fortunately, there are tools and channels that enable smooth exchange of information. There are tools that facilitate the exchange of thoughts, ideas and opinions such as blogs, websites, conferences and business meetings. Digitization has made it possible to propagate information while providing ready access to information, thereby, consuming less amount of time.

Read MoreFuture of Reverse Engineering

Reverse engineering found its use in various industries gradually, as more and more industry leaders adopted this approach and implemented the same, thereby easing out their own work-process. Here is a list of industries that use reverse engineering as a part of their methods: The future It is the 21st century. These are great times for design engineers. Over the past two decades, their job has been dramatically changed, with the transformation of finite element analysis (FEA) software from mainframe to desktop computer. With the easy availability of computer-aided design software packages, reverse engineering technology has become a practical means to create a 3D virtual model of an existing physical part. That, in turn, has made the use of 3D CAD, CAM, or other CAE applications easier. The convenience in the usage, affordability and the ability of its software to tightly integrate with a CAD program has made this process a much favored among engineers. At the same time, the costs of scanners and other hardware used to input measurements have been dropping, and the hardware is becoming smaller and easier to use, according to the hardware makers.

Read MoreReverse Engineering Inspection and its use

The quality control and inspection process in reverse engineering usually take three steps to determine if the 3D CAD model of the part is available or not. Those three steps are as follows: Following are some uses of Reverse engineering inspection:

Read MoreWhat are Parametric and Non-parametric Modeling

Table of content Parametric Model/Modeling Non-parametric Model/Modeling In the past, designers resorted to the physical measurement of the product to redraw its geometry. Today, designers use 3D scanners to capture measurements. The scanned data is then imported to CAD, where the design can be analyzed, processed, manipulated, and refined. Two key aspects that fall in place when focusing on the reverse engineering process are: Parametric Model/Modeling A parametric model captures all its information about the data within its parameters. All you need to know to predict a future data value from the model’s current state is its parameters. The parameters are usually finite in dimensions. Knowing the parameters for a parametric model to predict new data is enough. A parametric model is one where we assume the ‘shape’ of the data and, therefore, only have to estimate the coefficients of the model. A significant advantage of parametric modeling is that it compactly describes the underlying process, making further data processing more accessible. However, most work in parametric system identification relies on the assumption of time-invariance of the system and stationarity of the observed signal. But this assumption is not valid for all signals. In these cases, a heuristic approach often determines the optimal reduced model. Parametric models keep a history of the parameters that determine a model’s geometry. As a result, they allow the user to explore different design options while minimizing edit time. Similarly, parametric models can be visualized in 3D drawing programs. It means that they can more closely simulate the actual behavior of the original project. Non-parametric Model/Modeling A non-parametric model can capture more subtle aspects of the data. It allows more information to pass from the current set of data attached to the model at the current state to predict future data. The parameters are usually said to be infinite in dimensions. Hence, it can express the characteristics in the data much better than parametric models. For a non-parametric model, predicting future data is based not just on the parameters but also on the observed data state. A non-parametric model is one where we do not assume the ‘shape’ of the data, and we have to estimate the most suitable form of the model, along with the coefficients. Parametric models require a fixed number of parameters, while non-parametric ones don’t. The former is better for models with well-defined and predictable input data. Non-parametric models can be trained with a more significant number of data. However, the disadvantages of a parametric model are greater training time. While both models effectively predict the future, the latter tends to produce better results. The former requires less training data but is faster than non-parametric methods. Non-parametric models have the disadvantage of overfitting because they need many observations to approximate f. Non-parametric models have a much lower precision rate but can produce better-fitting models. As for the disadvantages of both models, parametric models are generally easier to understand and use. Besides requiring less training data, parametric models tend to produce poorer results. It is why they are more popular. However, the benefits of non-parametric algorithms are far outweighed by their disadvantages. The latter is often better for data that are not linear or have many missing values. Parametric models use different methods to estimate model parameters. Parametric modeling is based on mathematical functions, while non-parametric models are based on data. The difference between the two is a big one and can make the difference between success and failure in the field of statistics.

Read MoreThe Reverse Engineering process

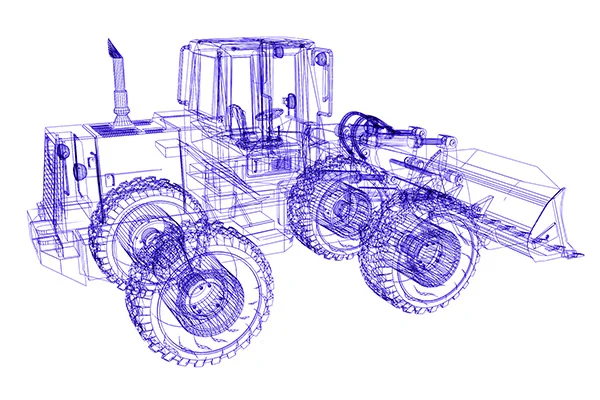

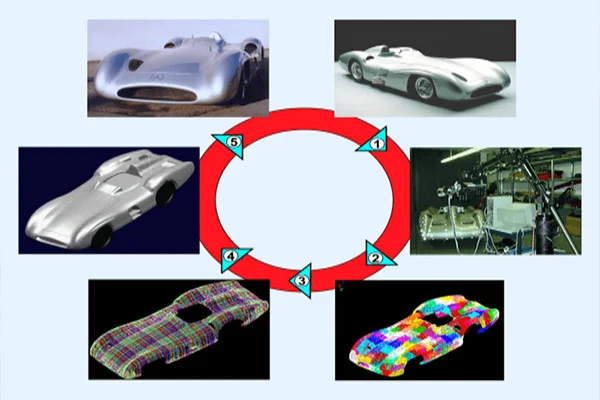

Sometimes, situations arise where you don’t have access to a part’s original design documentation from its original production. This might be due to the absence of the original manufacturer altogether or stoppage on the production itself. Reverse engineering empowers us to analyze a physical part and explore how it was originally built to replicate, create variations, or improve on the design. The goal is to ultimately create a new CAD model for use in manufacturing. Let us take a look at the steps involved in reverse engineering. Commonly, it involves careful executions of the following steps: Scanning The first step involves using a 3D scanner for collecting the geometric measurements and dimensions of the existing part quickly and accurately using projected light patterns and camera system. Generally, the types of scanners used for such execution are blue light scanner, white light scanner, CT scanner and /or laser scanner. The former two captures the outward dimension and measurements while the latter two is capable of scanning the entire inside out. Point Cloud Once a certain part is scanned, the data gets transformed in the form of point clouds. Point cloud is a 3D visualization consisting of thousands or even millions of points. Point clouds define the shape of a physical system. Meshing/Triangulation This stage serves involves conversion of point clouds to mesh (STL or Stereolithographic format). Mesh generation is the practice of converting the given set of points into a consistent polygonal model that generates vertices, edges and faces that only meet at shared edges. Common software tools used to merge point clouds are Polywords, Geomatics, Image Ware, MeshLab. The meshed part is then run for alignment in the mentioned software tools. Parametric/Non-parametric Modeling After the meshed part is aligned, it goes through either of two stages. The first option involves applying surface modeling on meshed part in tools such as Polyworks. It results in the generation of non-parametric model (IGES or STEP format). An alternate option is creating a sketch of the meshed part instead of putting it through surfacing. This work-process is known as parametric modeling (.PRT format). For a non parametric model, predicting future data is based on not just the parameters but also in the current state of data that has been observed. For a parametric model to predict new data, knowing just the parameters is enough. CAD Modeling The next stage consists of transferring the data through CAD software tools such as NX, Catia, Solidworks, Cero etc., for applying functions such as ‘stitch’, ‘sew’, ‘knit’, ‘trim’, ‘extrude’, ‘revolve’ etc for creation of 3D CAD model. Inspection This stage includes visual computer model inspections and alignment of the merged models against actual scanned parts (STL) for any discrepancies in the geometry as well as dimensions. Generally, inspection is carried out by using tools such as Polyworks or Geomagic. Reverse engineering inspection provides sufficient information to check tolerances, dimensions and other information relevant to the project. Documentation Documentation of 3D stage model depends solely on one’s technical/business requirements. This step is about converting 3D model to 2D sketch, usually with the help of tools such as inventor or Isidra/Coral draw, citing measurements which can be used for reference in the future.

Read MoreWhat is Reverse Engineering ?

Let us start with an example. One day you get into your garage and find on the workbench a ‘black box’. Stricken by curiosity, you build up an urge to discover what it ‘is’ and what it ‘does’. You start with an inspection of the box’s dimensions, color. Then you try to find its purpose and then how it operates. Not satisfied, you try to open it, break it apart, piece by piece in an attempt to understand what each component does and build up a pattern of how they would all interact together as one system. Finally you reach the end of your inquisition. You now fully (or partially) understand the box. This very approach is termed as Reverse Engineering.Reverse engineering, also known as back engineering, is the process where a man-made object is dismantled completely to reveal its architecture, design or to extract knowledge from the object about its functioning and structural integrity. Why do you need Reverse Engineering? There might be innumerable reasons to adopt reverse engineering process. Some of the common cases are as follows:

Read More